Non-woven-fabric filter

A filter and non-woven fabric technology, applied in the field of water treatment, can solve the problems of easy accumulation of bacteria, high production cost, easy formation of bacterial clusters, etc., and achieve the effect of good filtering effect, low production cost and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

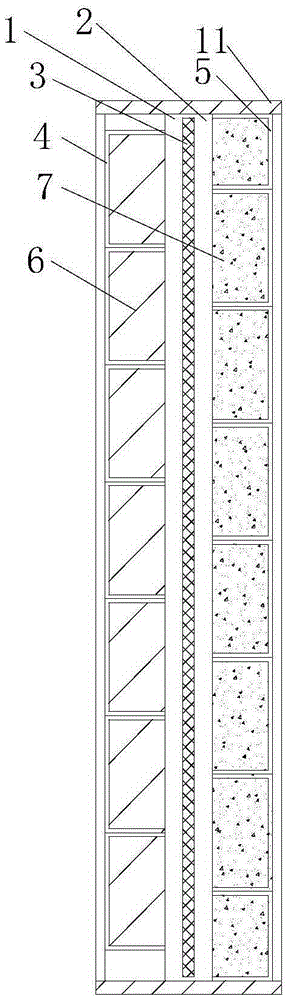

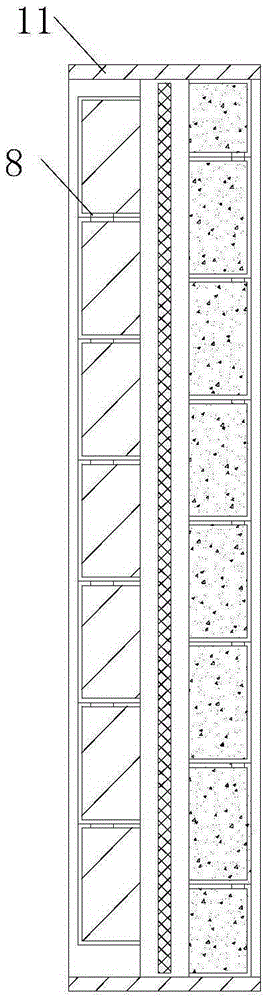

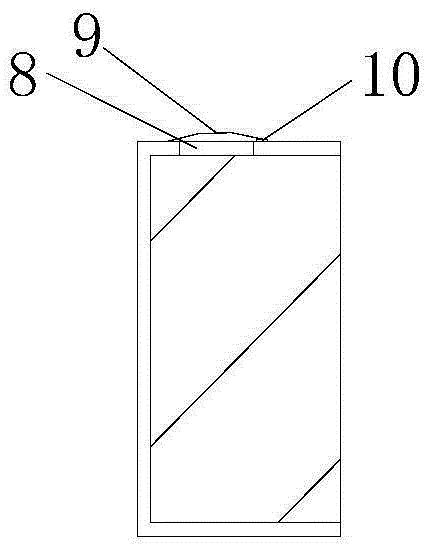

[0015] see Figure 1-Figure 3 Shown, a kind of nonwoven fabric filter; It is characterized in that, comprises frame body 11 and is arranged with the filter element in frame; Described filter element comprises first nonwoven fabric layer 1 and second nonwoven fabric layer 2, first, A support net 3 is arranged between the second non-woven fabric layers; some first non-woven fabric bags 4 are uniformly distributed on the first non-woven fabric layer, and some second non-woven fabric bags 4 are evenly distributed on the second non-woven fabric layer. Cloth bag 5; First filter material 6 is all arranged in the cavity formed between the first non-woven bag and the first non-woven layer; The second non-woven bag and the second non-woven The second filter material 7 is arranged in the cavity formed between the layers. Since the first and second filter materials are respectively arranged in the first and second non-woven bags to achieve secondary filtration, the filtering effect is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com