Sludge filter pressing device for sewage treatment

A technology for sludge press filtration and sewage treatment, which is used in water/sewage treatment, water/sludge/sewage treatment, and sludge treatment, etc. It can solve problems such as insufficient filtration, impurity cannot be filtered out in time, and inconvenient classification and treatment. problems, to achieve the effect of improving the cleaning effect and cleaning efficiency, and improving the degree of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

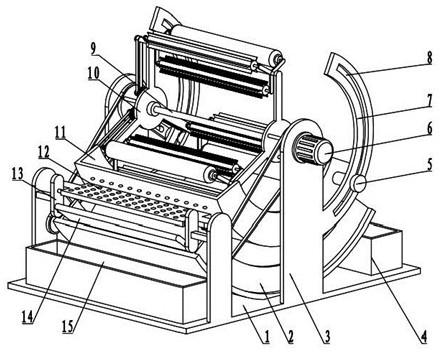

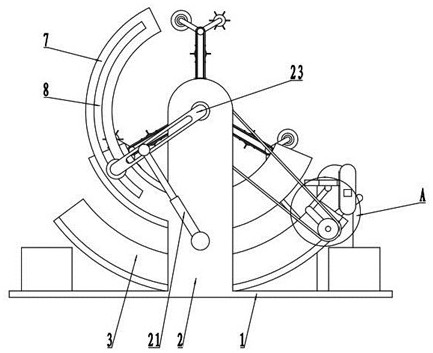

[0028] see Figure 1-7 , a sludge filter press device for sewage treatment, including a bottom plate 1, and also includes:

[0029] The fixed plate 3 fixedly arranged on one side of the bottom plate 1, the drive column 9 is arranged between the fixed plates 3, and the side of the fixed plate 3 on the side of the drive column 9 is fixedly connected to the drive motor 6;

[0030] The filter press mechanism arranged on one side of the drive column 9 includes an installation assembly and a transmission assembly. A filter press tank 11 is arranged on one side of the installation assembly, and the filter press tank 11 is an arc-shaped structure. One end of the installation assembly is provided with a fixing frame 17 , the fixed frame 17 is a three-terminal protruding structure, and the fixed frame 17 is respectively connected to the mud pressing roller 18, the mud scraping cylinder 19 and the scraping material cylinder 20, and the wall of the mud scraping cylinder 19 is fixedly conn...

Embodiment 2

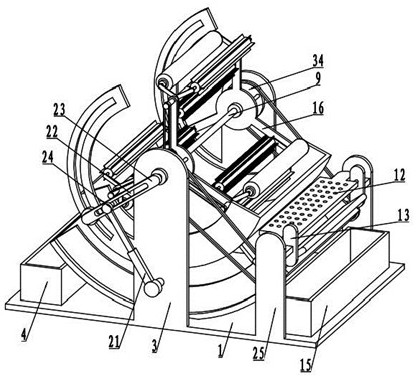

[0034] see Figure 1-7 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the installation assembly includes installation disks 10 fixedly arranged at both ends of the drive column 9, one side of the installation disk 10 is fixedly connected to the connecting rod 30, and the connecting rod 30- One side of the drive wheel 34 is fixedly connected, and one side of the drive wheel 34 is rotationally connected with the fixed plate 3. At least one installation rod 16 is arranged on the side wall of the installation disk 10, and the installation rod 16 is fixedly connected with the installation disk 10. One end of the installation rod 16 is connected to the installation disk 10. Fixed mount 17 is connected in rotation.

[0035] The transmission assembly includes a driving gear 26 arranged on one side of the mounting plate 10, the side wall of the mounting plate 10 on the axial side of the driving gear 26 is fixedly connected to the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com