Method for connecting vertical seams between adjacent load-bearing wallboards in floors

A connection method and wall panel technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of low strength, weak connection, easy aging, etc., and achieve the effect of high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

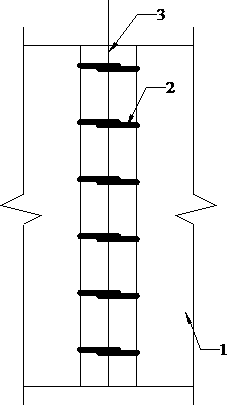

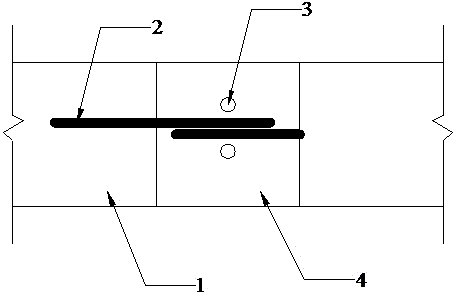

[0009] Such as figure 1 with figure 2 As shown, in the vertical joints generated between adjacent load-bearing prefabricated wall panels 1 in the floor, the vertical reinforcement 2 is laid first, then the vertical reinforcement is welded and connected with the connecting reinforcement 3, and finally the concrete 4 is post-cast. The prefabricated wall panels connected by this method are firmly connected and have good safety.

[0010] The above is only a preferred embodiment of the present invention, and is not intended to limit the technical content of the present invention in any form. Any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention , all still belong to the scope of the technical solution of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com