High and large template support system model

A support system and tall formwork technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of expert demonstration plan deviation, low education level of construction workers, and increase the difficulty of technicians' work, so as to ensure toughness and firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

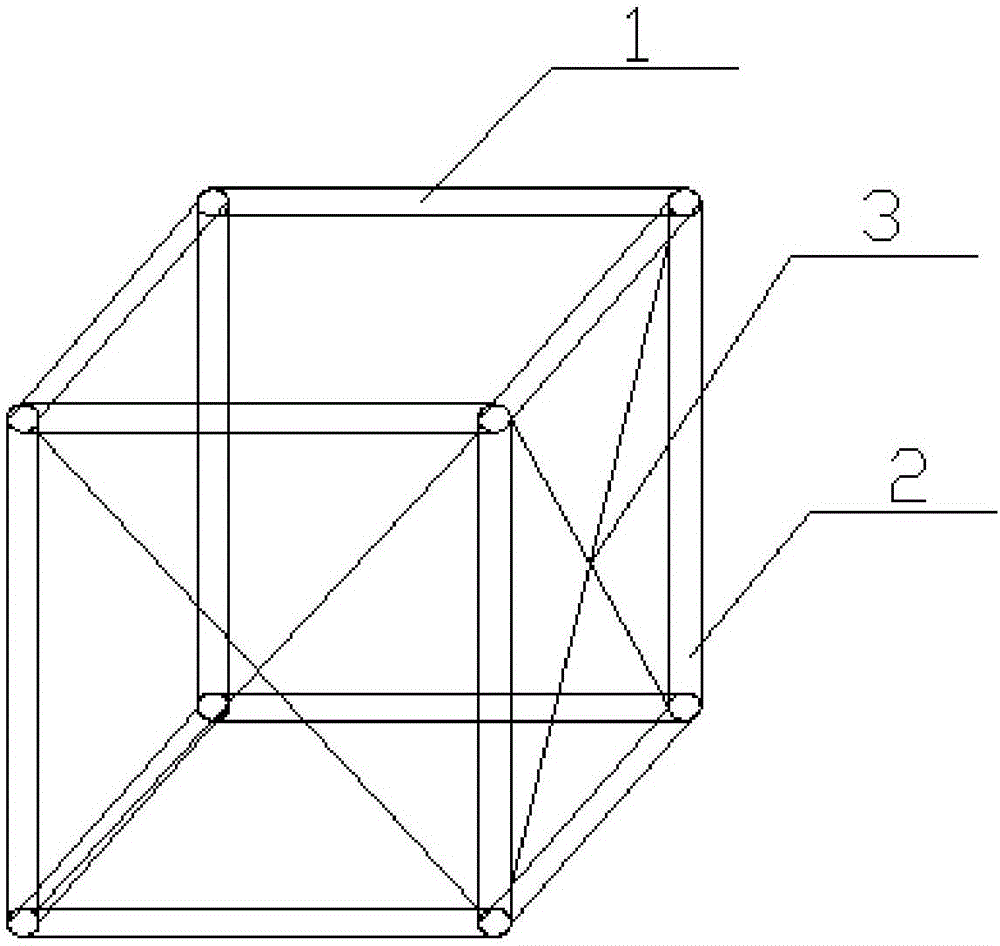

[0033] The tall formwork support system model, the model is in the shape of a cuboid as a whole, including horizontal bar 1, vertical bar 2, and scissor frame 3; the horizontal bar 1 and vertical bar 2 are welded to form a model frame, and the surface of the model frame is welded with scissor frame 3.

[0034] The horizontal bar 1, the vertical bar 2, and the scissors frame 3 are high-strength steel.

[0035] The high-strength steel is made of carbon, manganese, silicon, chromium, nickel, titanium, aluminum, sulfur, copper, iron, molybdenum, potassium, tin, cesium, iodine, lead, gold, tungsten, molybdenum;

[0036] The high-strength steel weight percentage is:

[0037] Carbon 0.02

[0038] Manganese 0.06

[0039] Silicon 0.05

[0040] Chrome 0.04

[0041] Nickel 0.005

[0042] Titanium 0.01

[0043] Aluminum 0.07

[0044] Sulfur 0.03

[0045] Copper 0.07

[0046] Molybdenum 0.04

[0047] Potassium 0.07

[0048] Tin 0.02

[0049] Cesium 0.03

[0050] Iodine 0.16

...

specific Embodiment 2

[0058] The tall formwork support system model, the model is in the shape of a cuboid as a whole, including horizontal bar 1, vertical bar 2, and scissor frame 3; the horizontal bar 1 and vertical bar 2 are welded to form a model frame, and the surface of the model frame is welded with scissor frame 3.

[0059] The horizontal bar 1, the vertical bar 2, and the scissors frame 3 are high-strength steel.

[0060] The high-strength steel is made of carbon, manganese, silicon, chromium, nickel, titanium, aluminum, sulfur, copper, iron, molybdenum, potassium, tin, cesium, iodine, lead, gold, tungsten, molybdenum;

[0061] The high-strength steel weight percentage is:

[0062] Carbon 0.1

[0063] Manganese 0.1

[0064] Silicon 0.25

[0065] Chrome 0.35

[0066] Nickel 0.5

[0067] Titanium 0.3

[0068] Aluminum 0.1

[0069] Sulfur 0.7

[0070] Copper 0.09

[0071] Molybdenum 0.09

[0072] Potassium 0.09

[0073] Tin 0.035

[0074] Cesium 0.25

[0075] Iodine 0.2

[0076]...

specific Embodiment 3

[0083] The tall formwork support system model, the model is in the shape of a cuboid as a whole, including horizontal bar 1, vertical bar 2, and scissor frame 3; the horizontal bar 1 and vertical bar 2 are welded to form a model frame, and the surface of the model frame is welded with scissor frame 3.

[0084] The horizontal bar 1, the vertical bar 2, and the scissors frame 3 are high-strength steel.

[0085] The high-strength steel is made of carbon, manganese, silicon, chromium, nickel, titanium, aluminum, sulfur, copper, iron, molybdenum, potassium, tin, cesium, iodine, lead, gold, tungsten, molybdenum;

[0086] The high-strength steel weight percentage is:

[0087] Carbon 0.2

[0088] Manganese 1.3

[0089] Silicon 0.4

[0090] Chromium 0.55

[0091] Nickel 0.6

[0092] Titanium 0.45

[0093] Aluminum 0.12

[0094] Sulfur 0.10

[0095] Copper 0.11

[0096] Molybdenum 0.13

[0097] Potassium 0.12

[0098] Tin 0.05

[0099] Cesium 0.54

[0100] Iodine 0.36

[010...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com