Automatic needle threading robot

A robot and automatic threading technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult assembly process, heavy talk, cumbersome and other problems, and achieve the effect of quick needle threading, good effect and tight coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

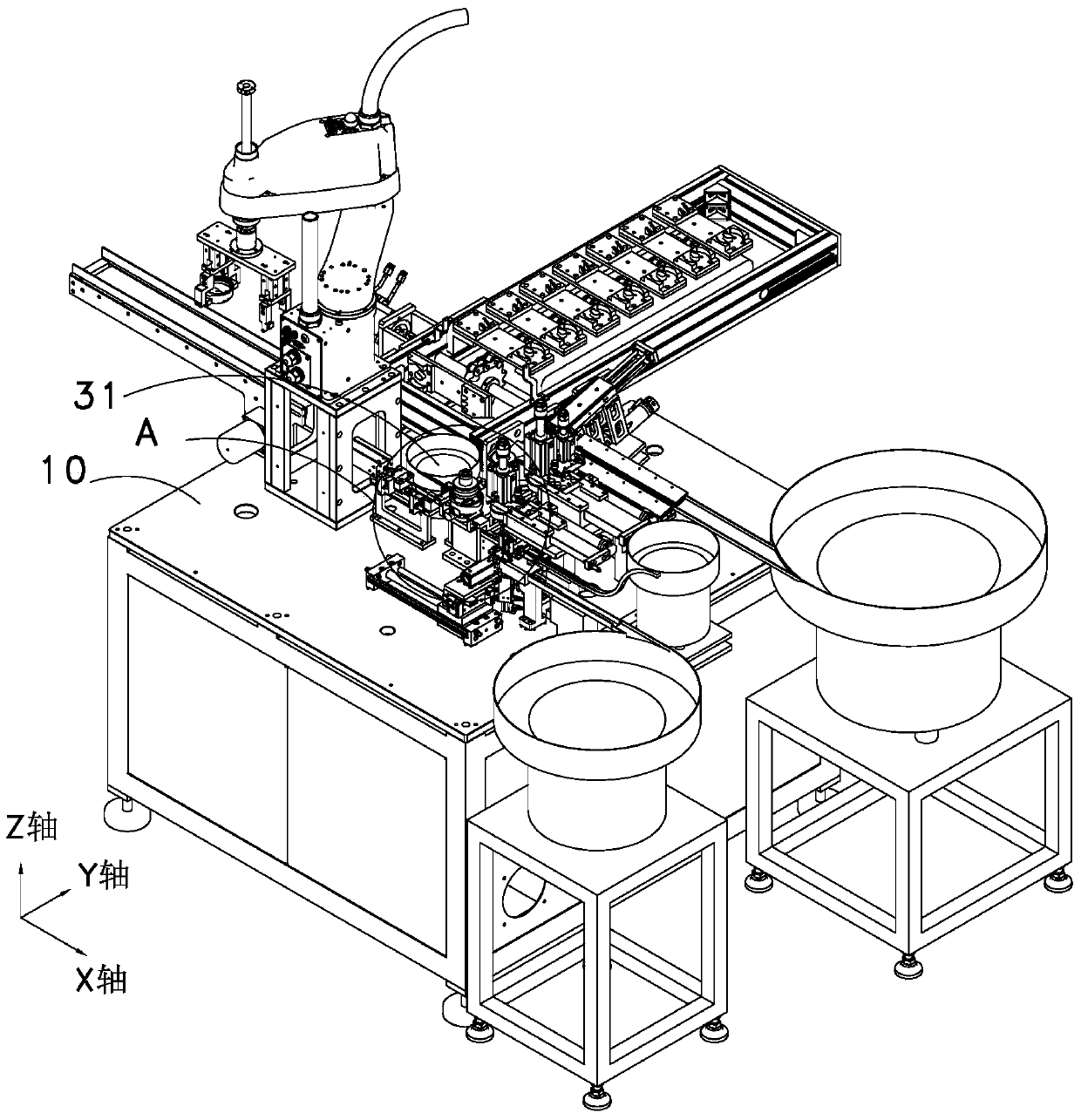

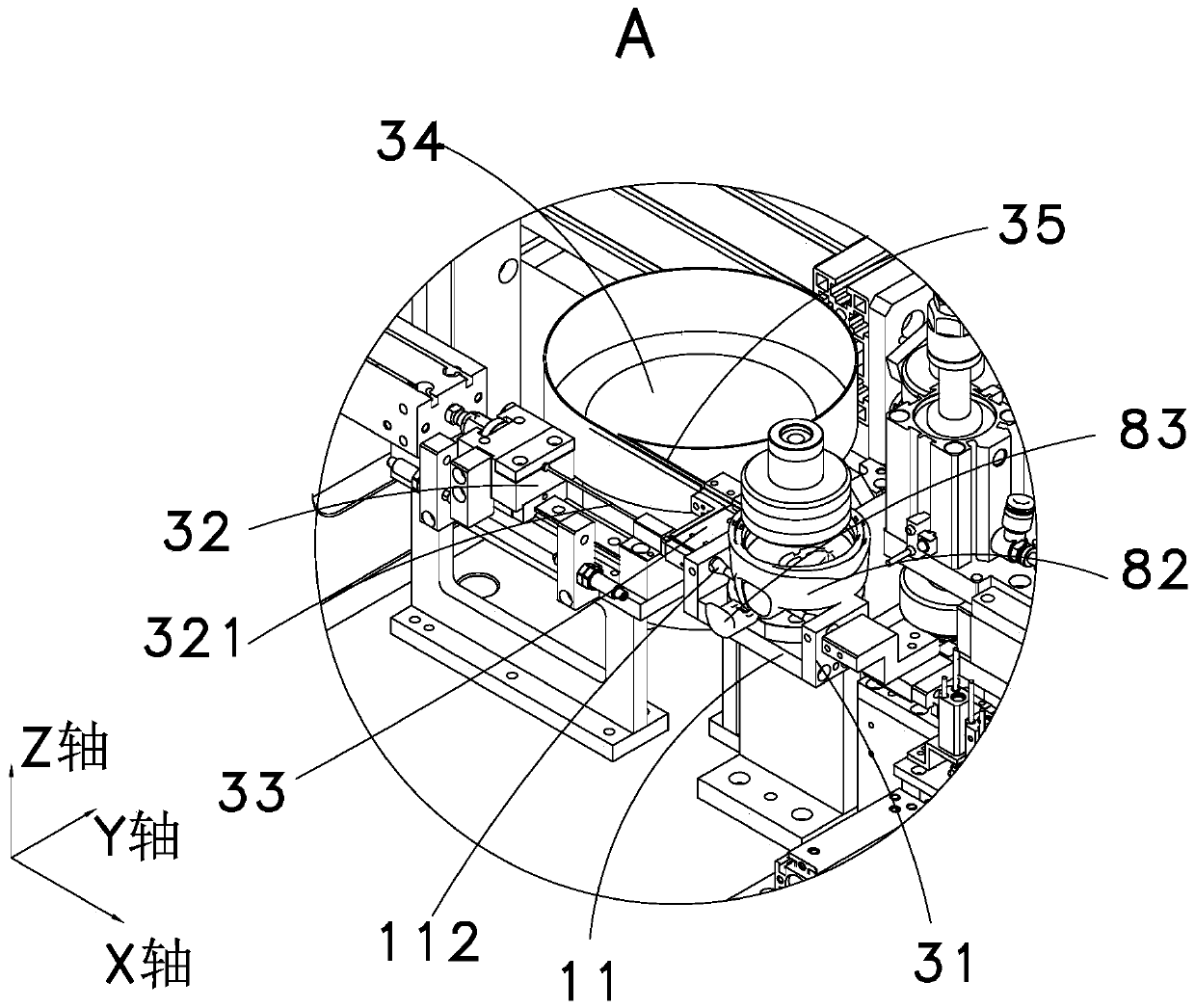

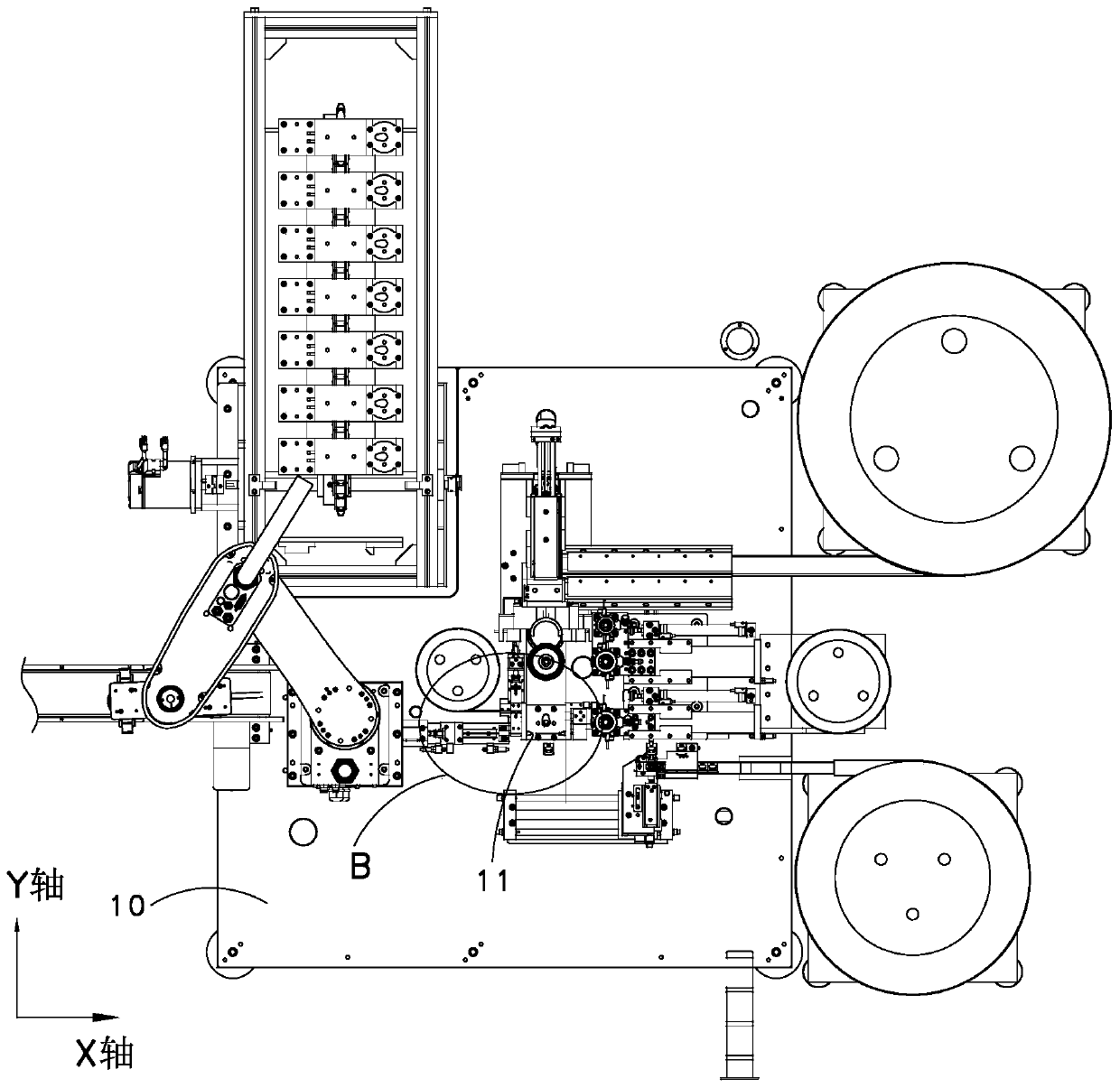

[0020] An automatic needle-threading robot, comprising a frame 10, a needle-threading station 11 fixedly arranged on the frame 10, slidably arranged on the frame 10 along the X-axis direction and located at the needle-threading station 11 A needle threading guide frame 31 on one side, a needle threading frame 32 slidably arranged on the frame 10 along the X-axis direction and located on the other side of the needle threading station 11, a needle transport frame 33 for transporting needles, And the program control mechanism, the needle delivery frame 33 is located between the needle threading station 11 and the needle threading frame 32, the needle threading frame 32 has a push rod 321, and the needle threading guide frame 31 has a Guide rod 311. One side of the needle threading station 11 is fixed with a first guide member 111 which facilitates the insertion of the guide rod 311 and corrects its position, and the other side of the needle threading station 11 is fixed with a T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com