Rubber composition improving anti-reversion performance and application thereof

A rubber composition and anti-vulcanization reversion technology, applied in the field of rubber, can solve the problems of unfavorable health and safety, a large amount of dust, etc., achieve low dynamic heat generation, good mechanical properties, and improve the effect of anti-vulcanization reversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

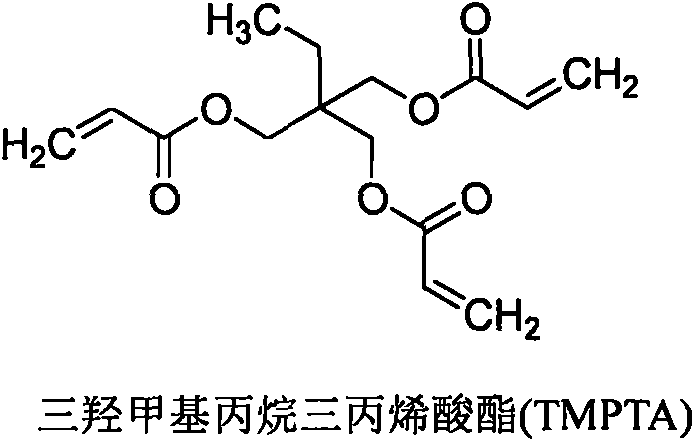

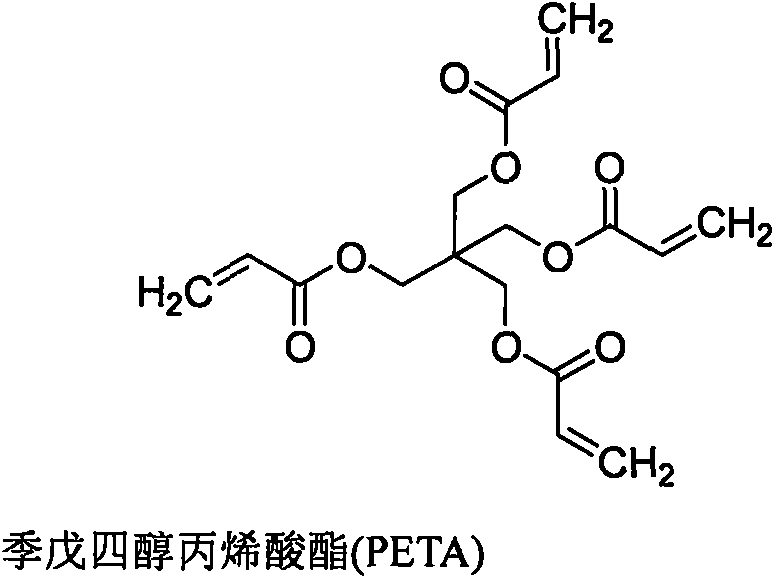

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. It should be pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they are all deemed to be included in the present invention.

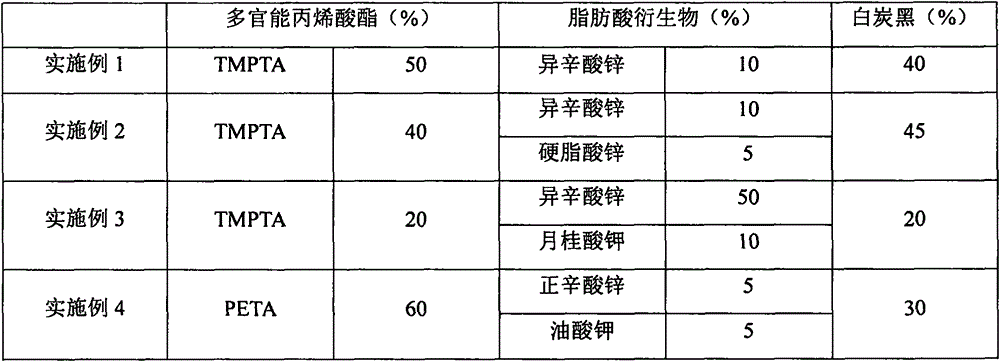

[0017] The anti-reversion agent composition and composition in Examples 1 to 4 are as follows:

[0018] Table 1. Anti-reversion agent components in Examples 1-4

[0019]

[0020] Components and sources in the embodiment rubber composition are as follows:

[0021] Natural rubber, SMR20, product from Malaysia;

[0022] Carbon black N326, Cabot (China) Investment Co., Ltd.;

[0023] Zinc Oxide, Dalian Zinc Oxide Factory;

[0024] Stearic acid, Tyko Browning;

[0025] Antiaging agent 4020, Jiangsu Sunon Chemical Co., Ltd.;

[0026] Antiaging agent RD, Jiangsu Sunon Chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com