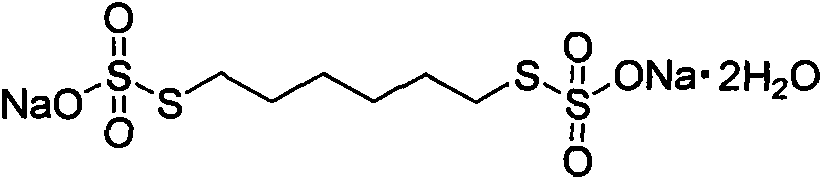

A kind of polymer containing polysulfide structure and preparation method thereof

A polysulfide and polymer technology, applied in the field of polymers containing polysulfide structure and its preparation, can solve the problems of reducing production process safety, loss of raw materials, long reaction time, etc., and achieve improved anti-vulcanization reversion performance , good repeatability, simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Sodium disulfide (Na 2 S 2 ) Preparation of aqueous solution

[0031] Use a 250mL four-neck flask equipped with a mechanical stirring device, a thermometer, and a reflux condenser as a reaction vessel, add 31.6g of sodium sulfide nonahydrate and 100g of water, stir and dissolve, add 12.7g of sulfur, stir and react at 50°C for 3.5h, then stop stirring , to obtain a sodium disulfide aqueous solution with a mass percentage concentration of 10%, which can be further diluted into a mass percentage concentration of 5-9% Na 2 S 2 aqueous solution.

[0032] Sodium tetrasulfide (Na 2 S 4 ) Preparation of aqueous solution

[0033] Use a 250mL four-necked flask equipped with a mechanical stirring device, a thermometer and a reflux condenser as a reaction vessel, add 43.2g of sodium sulfide nonahydrate and 85g of water, stir and dissolve, add 17.4g of sulfur, and stir at 60°C for 4 hours, then stop stirring. The obtained mass percent concentration is 30% sodium tetrasulfide ...

Embodiment 1~12

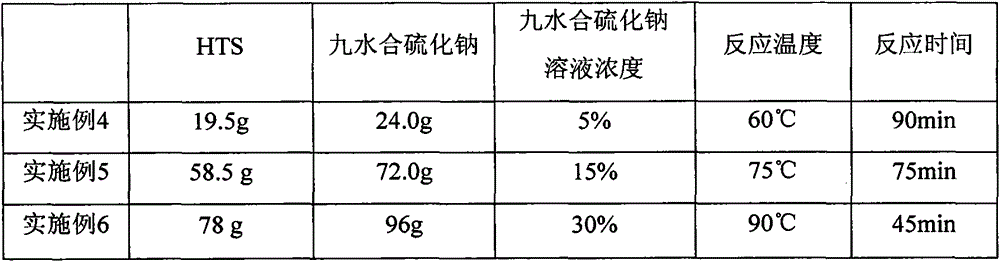

[0035] Examples 1-12: Using sodium sulfide nonahydrate and hexamethylene dihydrate 1,6-dithiosulfate disodium salt (HTS) as raw materials

Embodiment 1

[0037] Purge and stir the 500ml four-necked flask with nitrogen, and install a thermometer, a reflux condenser, and a stirrer. Add 39.0 g of HTS and 156.0 g of deionized water into the flask, turn on the stirrer, increase the internal temperature of the reactor, and completely dissolve the HTS in the water. The upper space of the reactor was purged with nitrogen again, and 120.0 g of 20% by mass aqueous solution of sodium sulfide nonahydrate was added. Then continue to raise the internal temperature of the reactor to 100° C., and stir the reaction at this temperature. During the reaction, the reaction solution gradually changed from transparent and clear to turbid, and the pH value of the reaction solution was controlled to be 12.0. After reacting for 60 minutes, a gelatinous substance was formed in the reactor, and the reaction liquid became transparent and clear, and the reaction was stopped and naturally cooled to room temperature. The reaction solution was poured out, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com