Emergent release device for ultralow temperature fluid handling equipment

A technology for loading and unloading equipment and disengagement devices, which is applied in the directions of liquid distribution, conveying or transfer devices, valve devices, mechanical equipment, etc., can solve problems such as marine pollution, reduced elasticity, and increased operating torque of oil cylinders, and achieves low manufacturing accuracy requirements. Consistent switching degree and small operating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

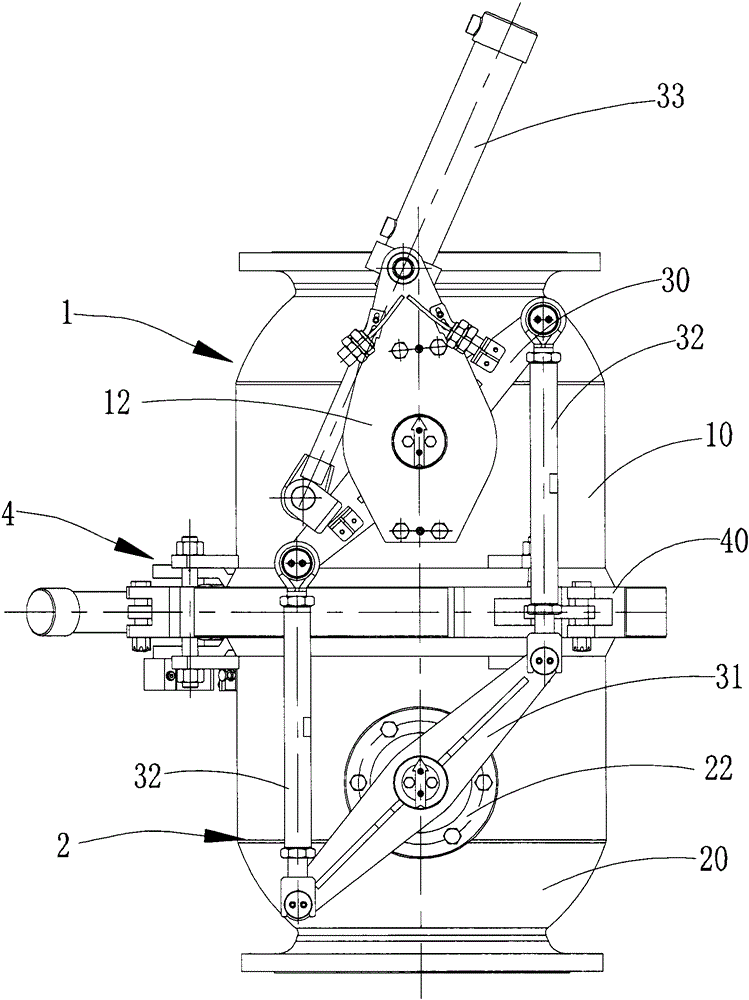

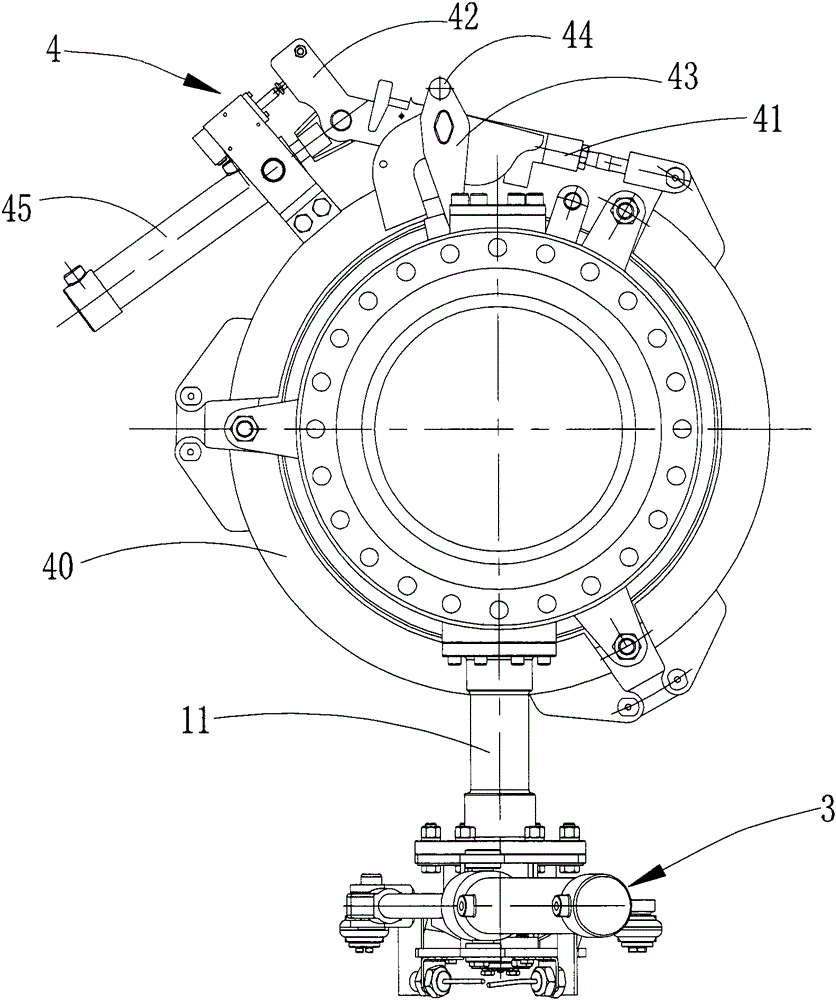

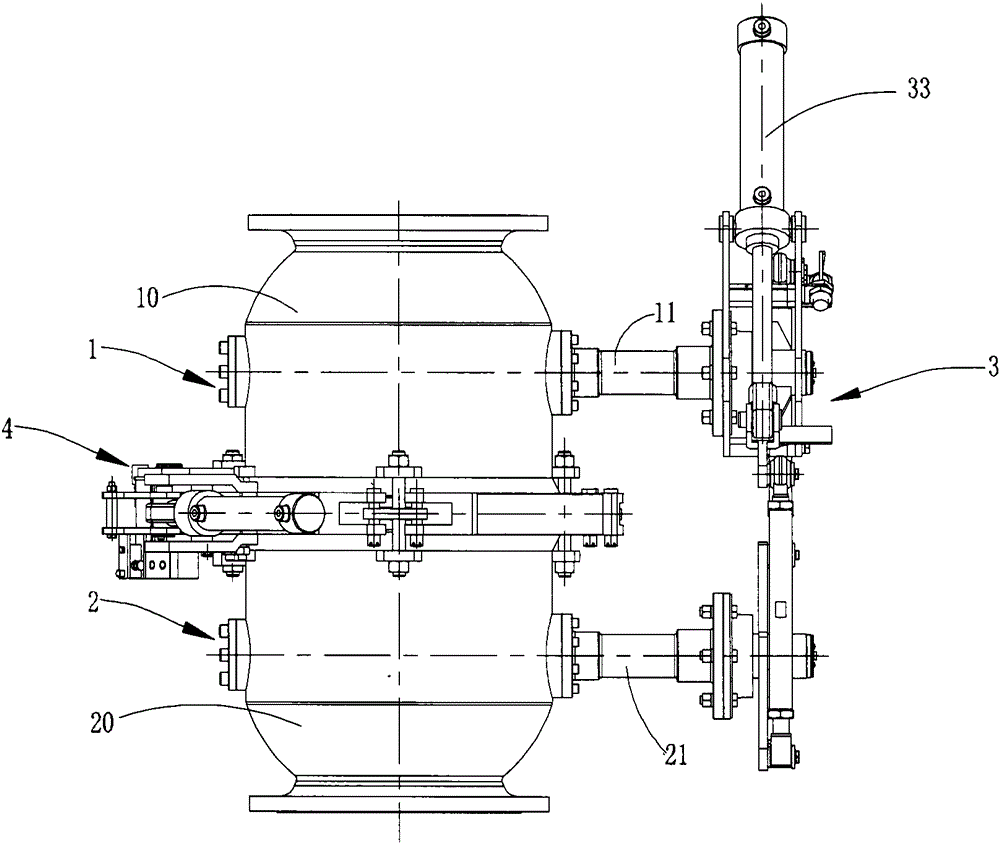

[0026] see Figure 1 to Figure 4 As shown, an emergency release device for ultra-low temperature fluid loading and unloading equipment includes two upper and lower ball valves, a valve switch mechanism 3 that drives the synchronous switching of the two ball valves, and a valve for controlling the two ball valves. A locking mechanism 4 for ball valves to be locked or disengaged from each other. By separating the valve switch mechanism 3 from the locking mechanism 4, the valve closing operation can also be realized when the loading and unloading arm is not in use to prevent fluid leakage. Here, the sequence of valve switching and disengagement is controlled by the hydraulic system of the loading and unloading arm .

[0027] Wherein, both the upper and lower ball valves include a valve body with an inner cavity, a valve stem inserted in the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com