A kind of thin-layer optical glue elastic modulus test method and sample

A technology of elastic modulus and test method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem that it cannot be used to measure the elastic modulus of thin-layer optical adhesives, and achieves the promotion of technology research and development and optimization, The effect of great practical application value and simple derivation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

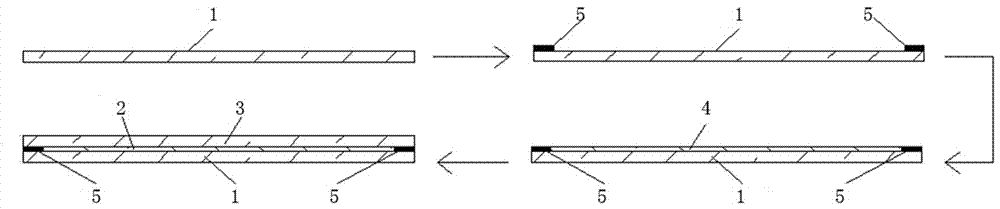

[0079] (1) Clean the bottom glass and the upper glass, the thickness of the bottom glass and the upper glass is 0.7mm, and the diagonal length is 20mm×50mm;

[0080] (2) Mix the glue of the A and B components of the optical glue in a ratio of 1:1, fully stir and defoam, to form a usable liquid optical glue;

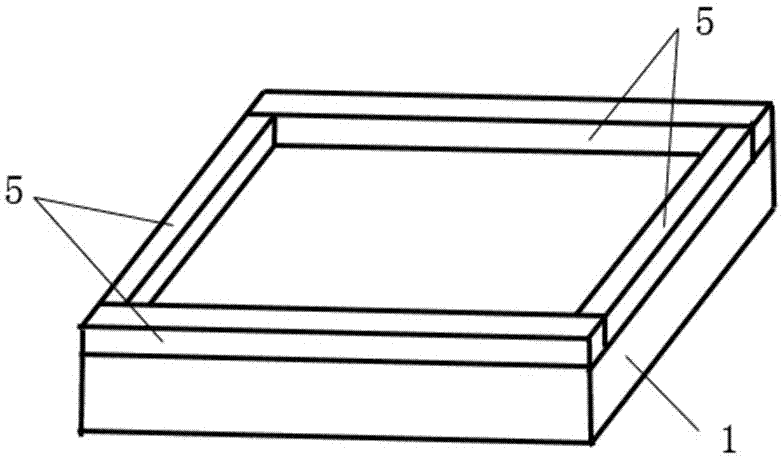

[0081] (3) Adhesive tapes with a thickness of 200 μm are fixed at the four corners of the bottom glass 1;

[0082] (4) Pour the liquid optical glue on the bottom glass and let it stand until the liquid optical glue flows freely and completely covers the bottom glass;

[0083] (5) Place the upper glass on the bottom glass and the liquid optical glue to form a sample with a three-layer structure;

[0084] (6) Put the sample into the oven for 3 hours, set the oven temperature to 70°C, and the liquid optical glue between the two layers of glass becomes solid optical glue;

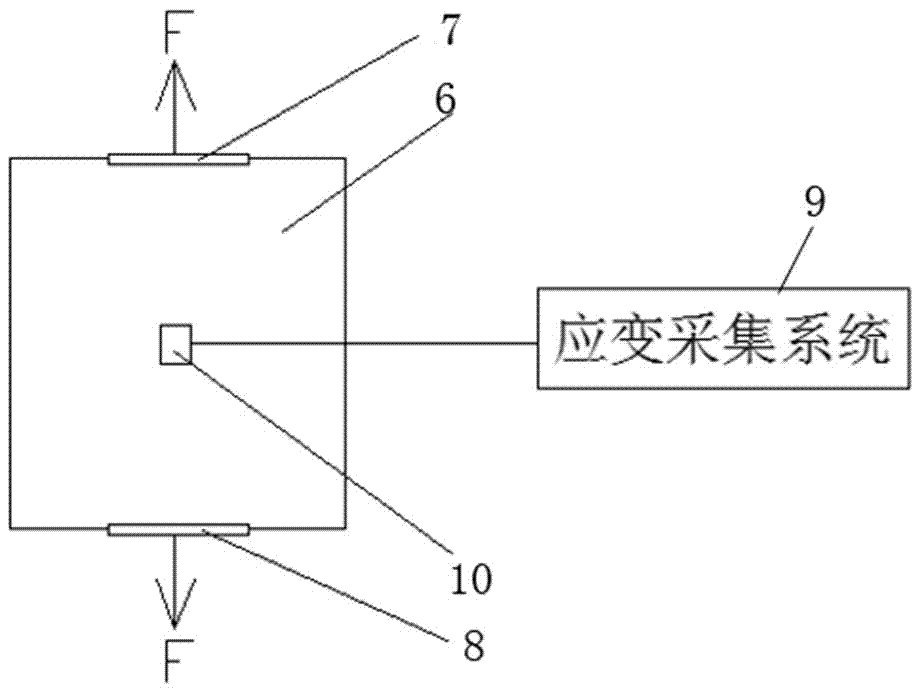

[0085] (7) Bond the strain gauge at the center of the cured sample;

[0086] (8) Fix the cured sampl...

Embodiment 2

[0092] In order to solve the difficult problem of testing the modulus of elasticity of optical glue with a fixed thickness of only a few hundred microns, the present invention proposes a method for testing the modulus of elasticity of thin-layer optical glue, which includes the following steps:

[0093] (1) Clean the bottom glass and the upper glass, the thickness of the bottom glass and the upper glass is 1.1mm, and the size is 174mm×315mm;

[0094] (2) Mix the glue of the A and B components of the optical glue according to the ratio of 1:1, fully stir and defoam, and form a usable optical glue;

[0095] (3) Fix tape with a thickness of 250 μm on the four corners of the bottom glass;

[0096] (4) Pour the optical glue on the bottom glass and let it stand until the optical glue flows freely and completely covers the bottom glass;

[0097] (5) Put the sample into the oven for 3 hours, set the oven temperature to 70°C, and the liquid optical glue between the two layers of glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com