Parallel irradiation reaction device

A technology of irradiation reaction and reaction container, which is applied in the field of parallel irradiation reaction devices, can solve problems such as the influence of light source life and inability to detect online, and achieve the effects of improving light distribution characteristics, increasing accuracy, and receiving light evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

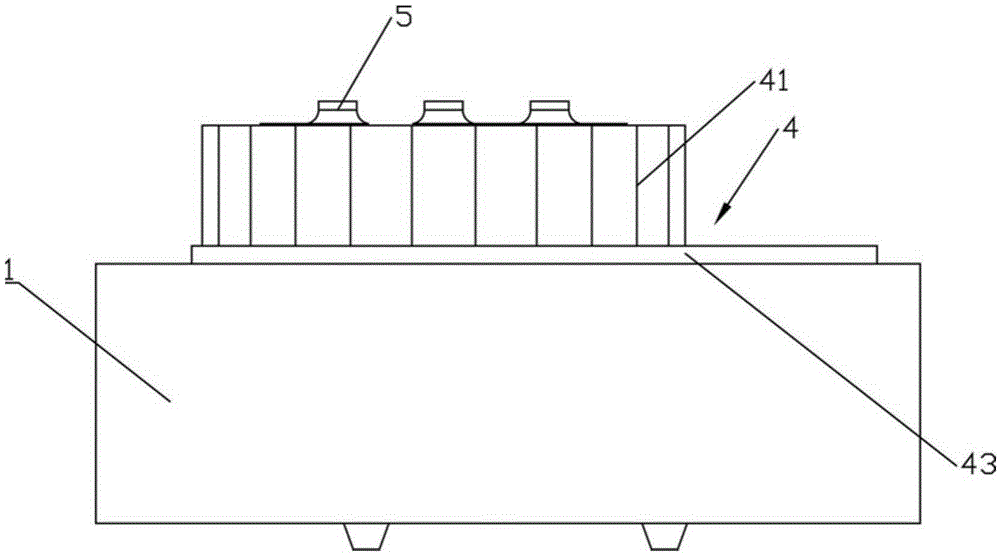

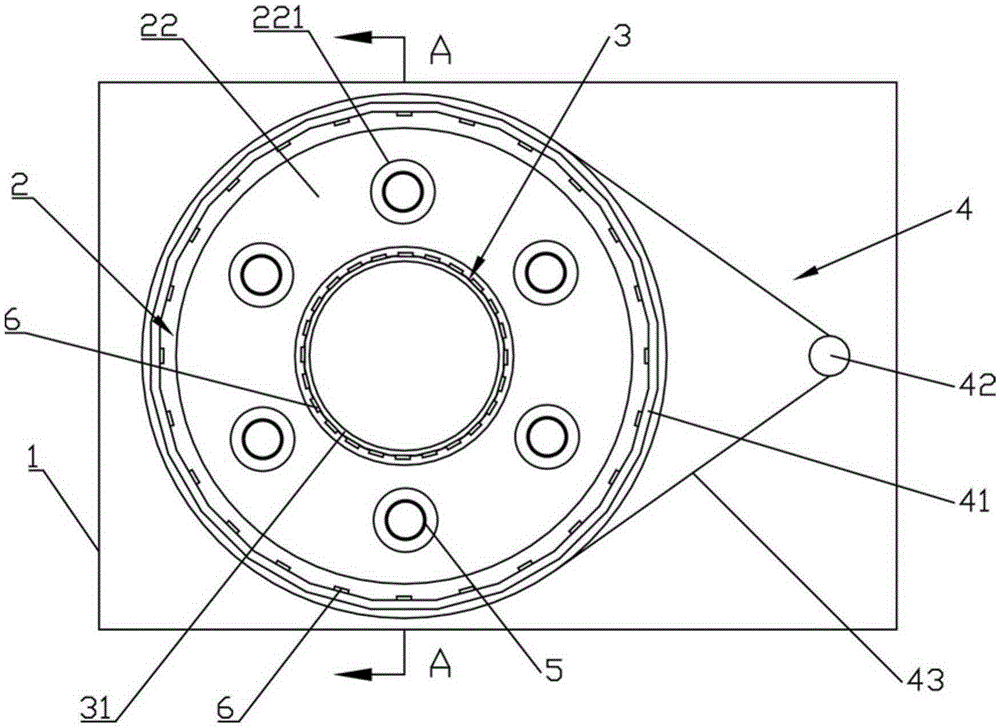

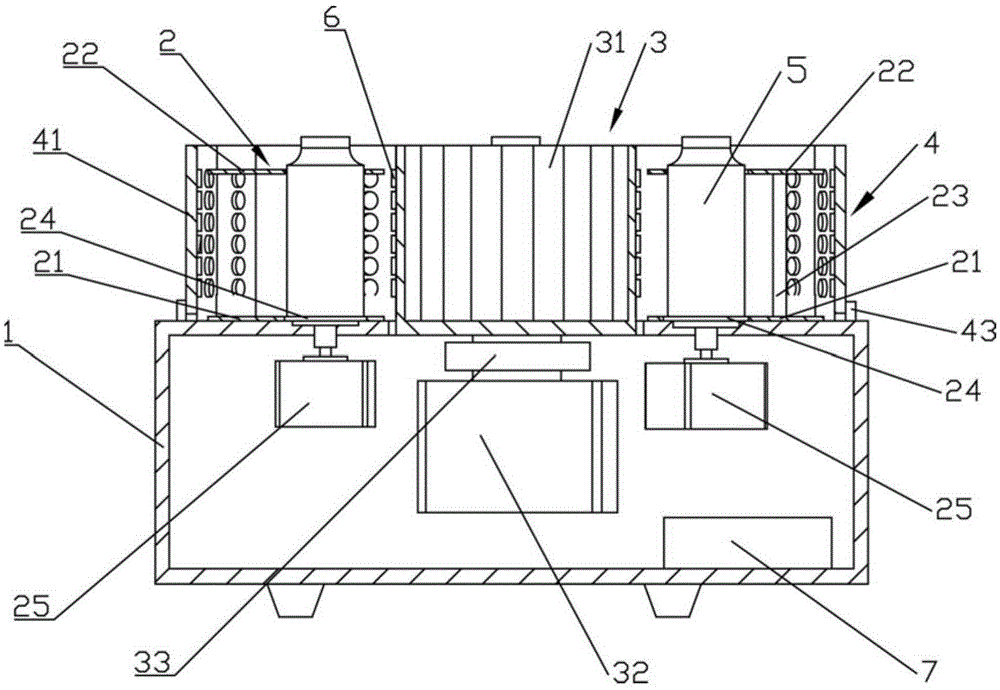

[0030] refer to Figures 1 to 3 As shown, the parallel irradiation reaction device of the present invention includes: a support 1, a sample holder 2 and an internal illumination mechanism 3, the internal illumination mechanism 3 includes an internal illumination motor 32 and an internal illumination cylinder 31, and the internal illumination cylinder 31 is a cylinder structure, the inner tube 31 can be rotatably arranged on the support 1 around its axis of rotation, that is, the inner tube 31 can rotate around its own axis of rotation; the inner tube 32 is connected with the inner tube 32, and the inner tube 32 is used To drive the inner cylinder 31 to rotate. The sample holder 2 is arranged on the support 1, and the sample holder 2 is located around the outside of the inner lighting tube 31 for holding the reaction vessel 5; the outer surface of the inner lighting tube 31 is provided with a plurality of light sources 6 for irradiating and placing Reaction vessel 5 on sample ...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, and the same parts as Embodiments 1 and 2 will not be repeated in this embodiment. Multiple light sources are not exactly the same, and more than two kinds of LED lamps, xenon lamps, mercury lamps and halogen lamps are used. For example can have following combination: (1) the light source on the inner lighting tube 31 all adopts LED lamp, and the light source on the outer lighting tube 41 all adopts xenon lamp; (2) the light source on the inner lighting tube 31 adopts LED lamp, xenon lamp And three kinds of mercury lamps; And the light source on the outer lighting tube 41 adopts three kinds of LED lamps, xenon lamps and halogen lamps. The use of different light sources has two advantages: (1) the reaction vessel can be irradiated with light of different wavelengths; (2) different light sources can be lighted for experiments in different reaction stages, without changing the filter, making the light source The selec...

Embodiment 3

[0042] This embodiment is basically the same as Embodiments 1 and 2, and the same parts as Embodiments 1 and 2 will not be repeated in this embodiment. (not shown in the figure), and a filter (not shown in the figure) is arranged between the outer tube 41 and the sample holder 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com