Same-tower multi-loop power transmission line strain insulator string electrification replacing method and device

A technology of strain insulator strings and live replacement, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of small safety distance, difficulty for operators to safely pass through the middle phase and lower phase cross arm, and small safety distance of upper line on the transmission line, etc. , to achieve the effect of expanding the operation window, improving the ability, and ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

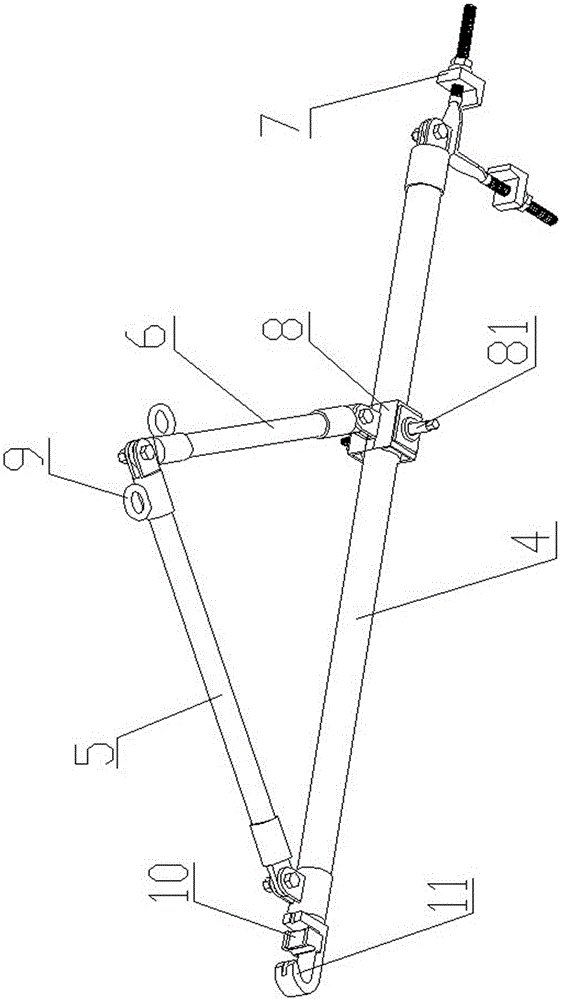

[0023] The tool insulation holding rods used in the specific implementation of the present invention are self-designed, and other tools used (such as insulation pulley, insulation transfer rope, insulation operating rod, screw mandrel, large knife fixture, insulation pull plate, bottle holder) are all in the field. Existing tools are commercially available. Except for the use of insulating poles, the methods of using other tools are well known to those skilled in the art. The steps of using these tools to remove and replace the insulator are well known to those skilled in the art. The key improvement point of the present invention lies in the step of enlarging the distance between the upper phase jumper and the work cross arm.

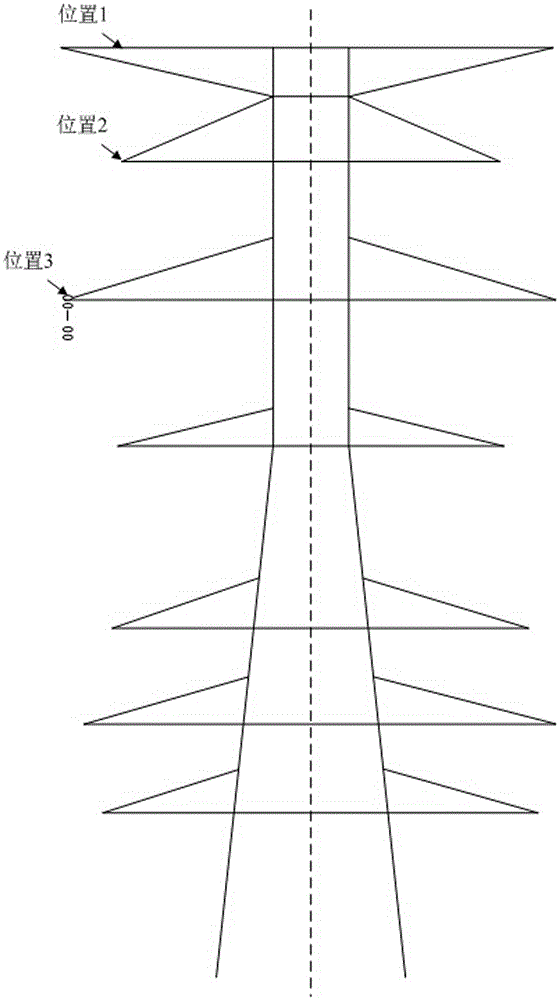

[0024] The following positions 1, 2, and 3 are respectively located in the upper phase cross arm, the middle phase cross arm, and the lower phase cross arm.

[0025] The insulating pole used in the present invention, as image 3 , including a suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com