Spraying device for heating radiators

A spraying device and radiator technology, applied in the field of radiators, can solve the problems of high labor intensity, low work efficiency, paint waste, etc., and achieve the effect of low labor intensity, high work efficiency and uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

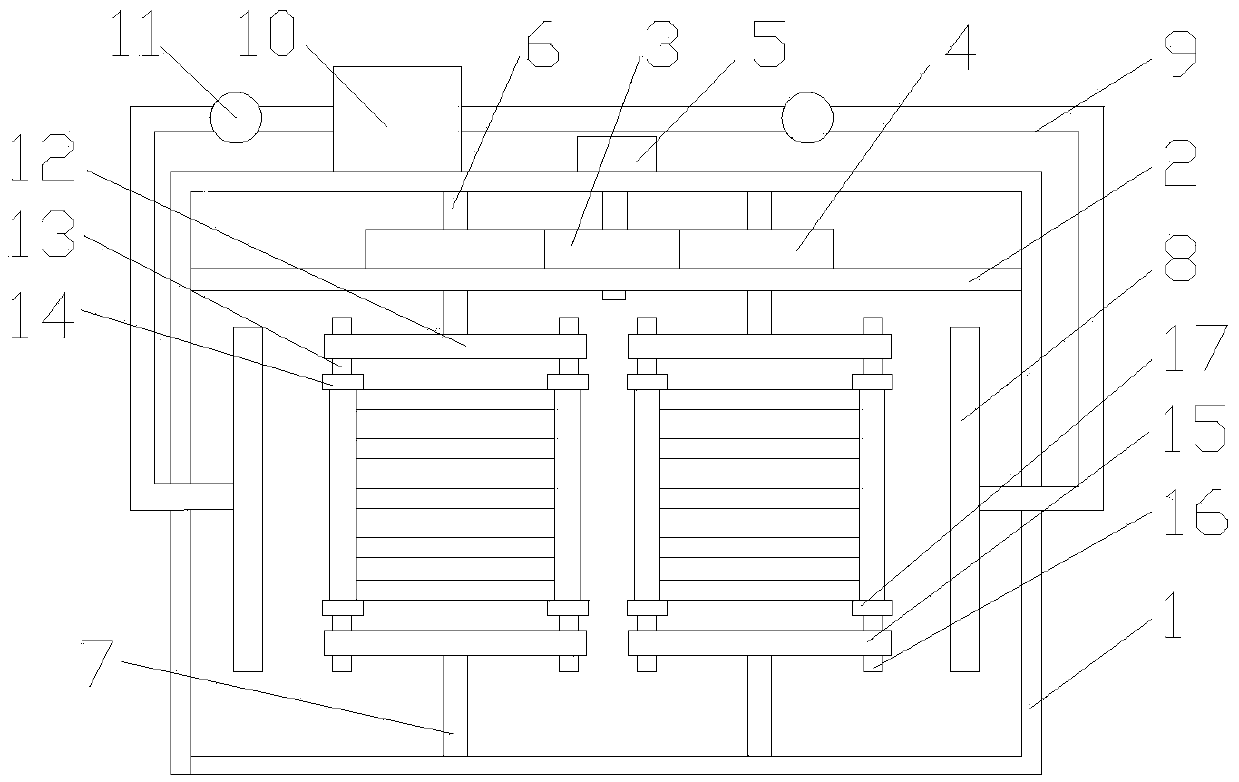

[0011] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a radiator spraying device proposed by the present invention.

[0012] refer to figure 1 , the present invention proposes a spraying device for radiators, comprising: a spraying chamber 1, a support plate 2, a driving gear 3, a plurality of driven gears 4, a driving device 5, a plurality of clamping mechanisms, a plurality of spray pipes 8, an infusion Pipeline 9, storage tank 10 and control valve 11; Support plate 2 is arranged in the spray booth 1, driving gear 3 and a plurality of driven gears 4 are all arranged on the support plate 2, and drive gear 3 is arranged on the spray booth 1 The driving device 5 is driven to rotate, and a plurality of driven gears 4 mesh with the driving gear 3. The number of clamping mechanisms matches the number of driven gears 4. The clamping mechanism includes an upper clamping assembly and a lower clamping assembly. The upper clamping assembly Including the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com