Consolidation repair agent for contaminated soil and preparation method thereof

A technology of polluted soil and remediation agent, which can be used in the restoration of polluted soil and other directions, and can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

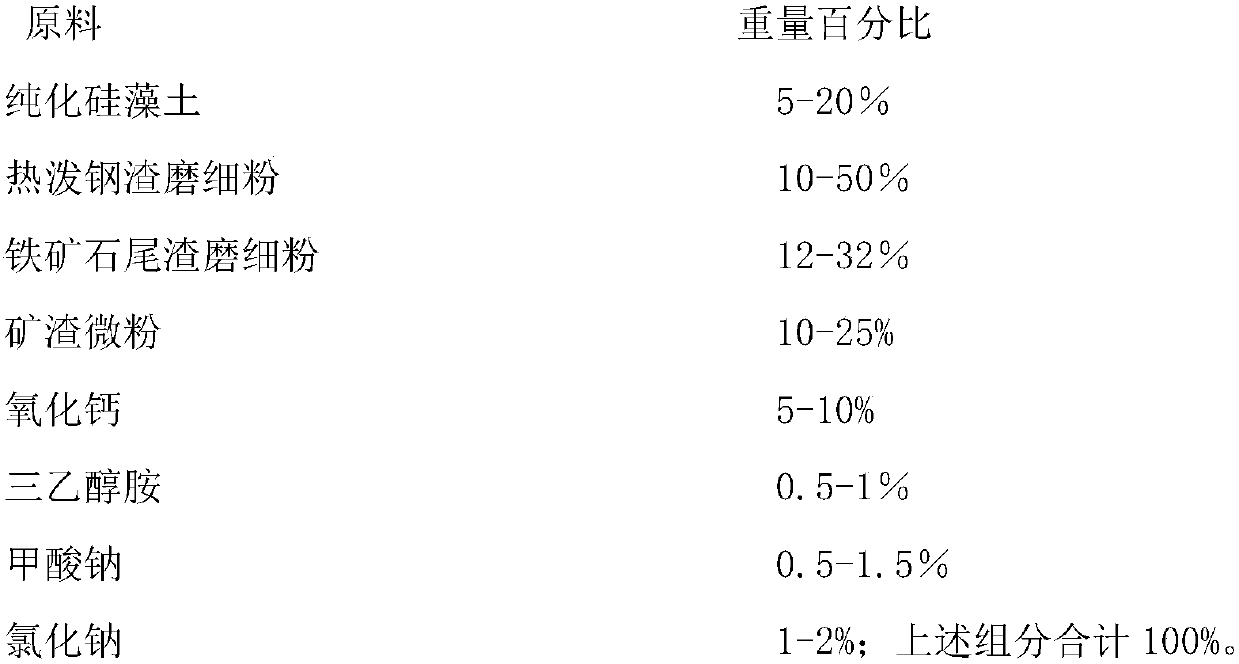

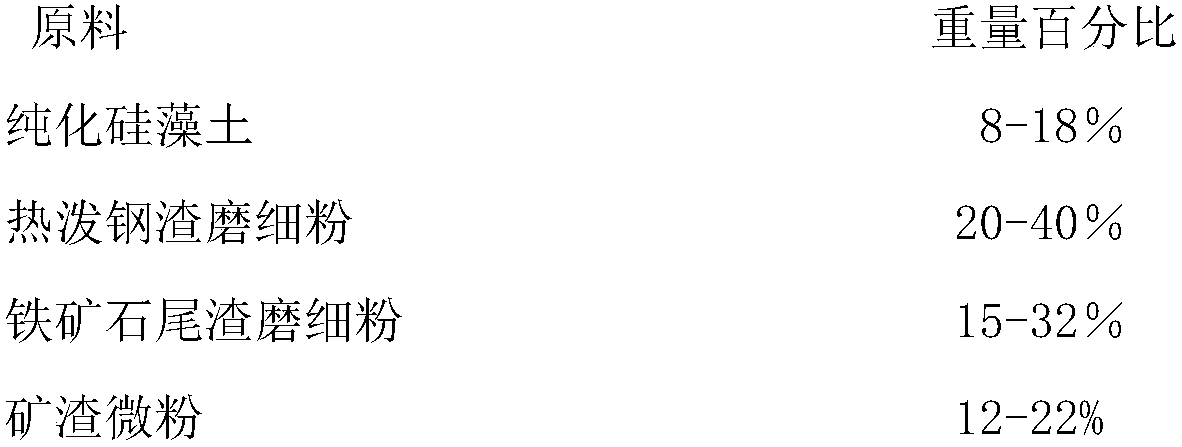

[0042] A kind of consolidation repairing agent related to polluted soil, it is made of the raw materials of following percentage by weight:

[0043]

[0044] A preparation method involving contaminated soil consolidation restoration agent, the steps are:

[0045]A. Soak steel slag, purified diatomite and iron ore tailings with 15% (volume concentration) hydrochloric acid for 3 or 4 or 5 hours respectively, in order to remove the inert components in steel slag, diatomite and iron ore tailings Erosion treatment is carried out, because steel slag and iron ore tailings are solid wastes produced by high temperature process, and the amorphous phase structure composed of calcium, magnesium, silicon and aluminum metal oxidation is dense on the surface, which is not conducive to the activation of activity. After being etched with hydrochloric acid, it is beneficial to other The activity is stimulated, and the acid soaking is beneficial to increase the lattice depression and defect r...

Embodiment 2

[0055] Take the sludge from WISCO Industrial Port Sewage Plant, mix it with silt according to the mass fraction of 12%, the mold is consolidated after mixing, demolded after 1 day, and the softening coefficient is measured to be 0.98 after curing for 7 days; the chemical erosion coefficient of acid, alkali and salt medium is 1.05; The permeability coefficient reaches 6*10 -8 cm / s. (see Example 3)

Embodiment 3

[0056] Take the polluted soil in Huanggang Wuxing Metal Products Factory, mix it with silt according to the mass fraction of 8%, the mold is consolidated after mixing, demolded after 1 day, and the softening coefficient is measured to be 0.99 after 7 days of curing; the chemical erosion coefficient of acid, alkali and salt medium is 1.02 ;Permeability up to 4*10 -8 cm / s. (see Example 4)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com