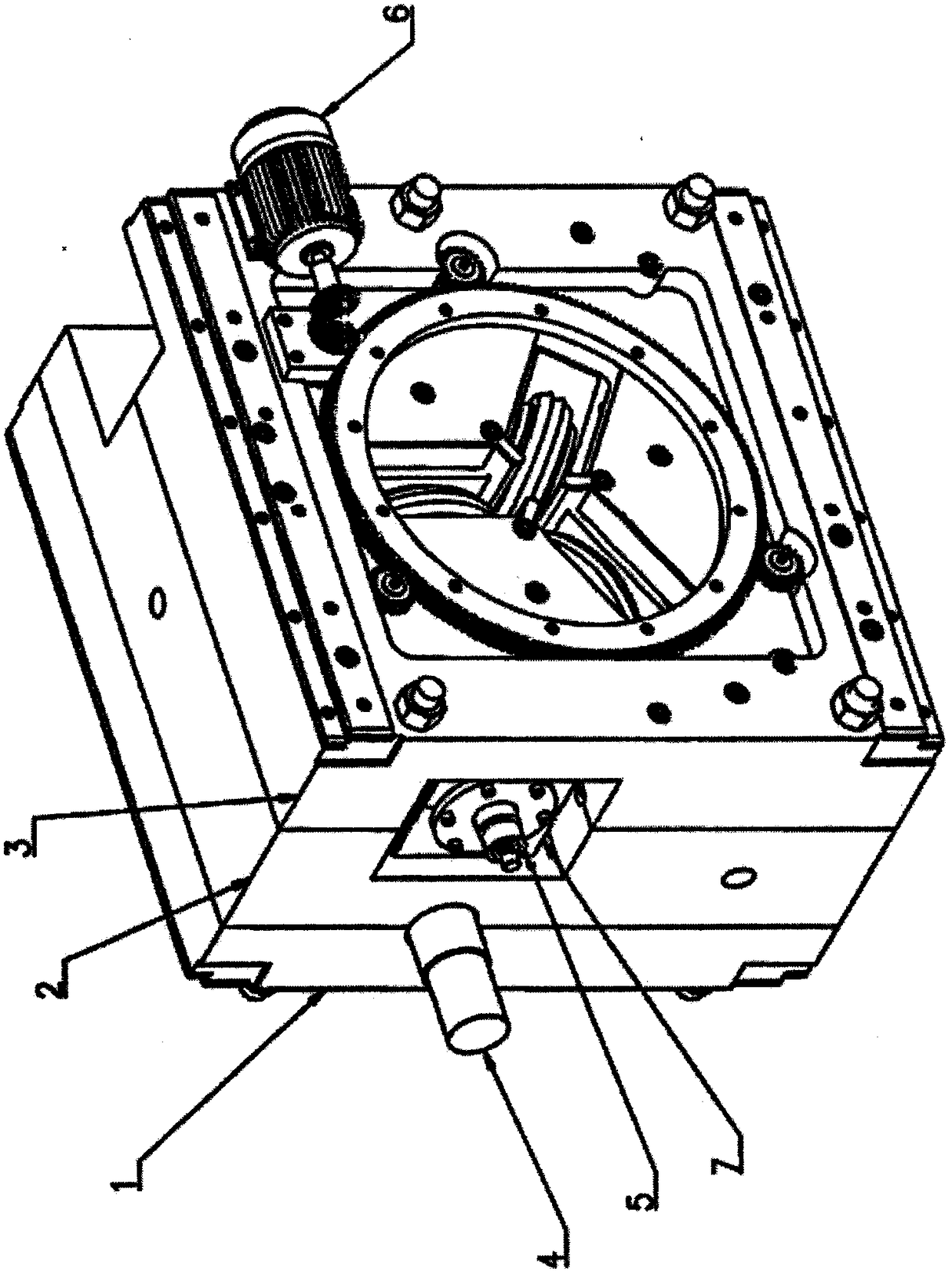

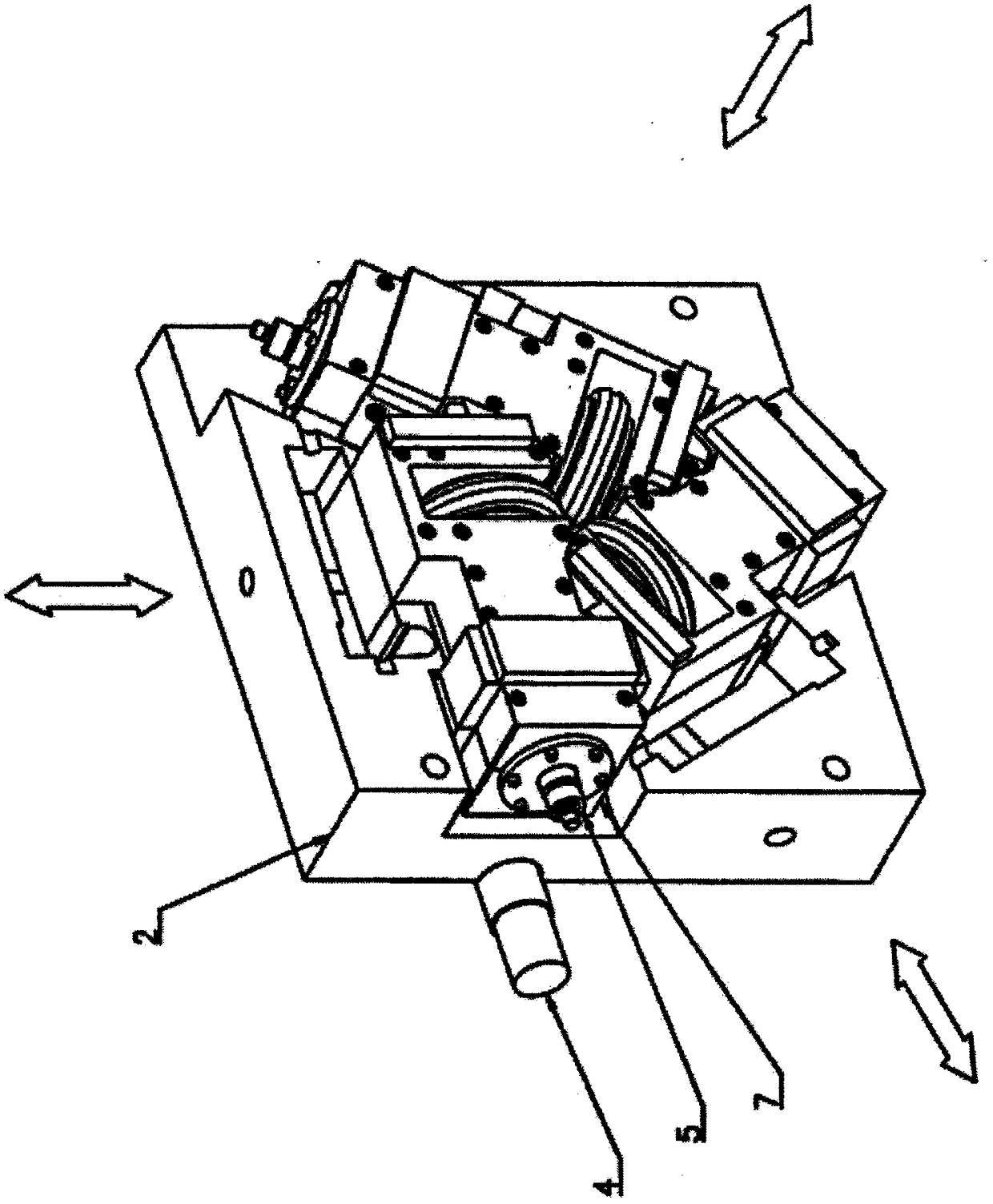

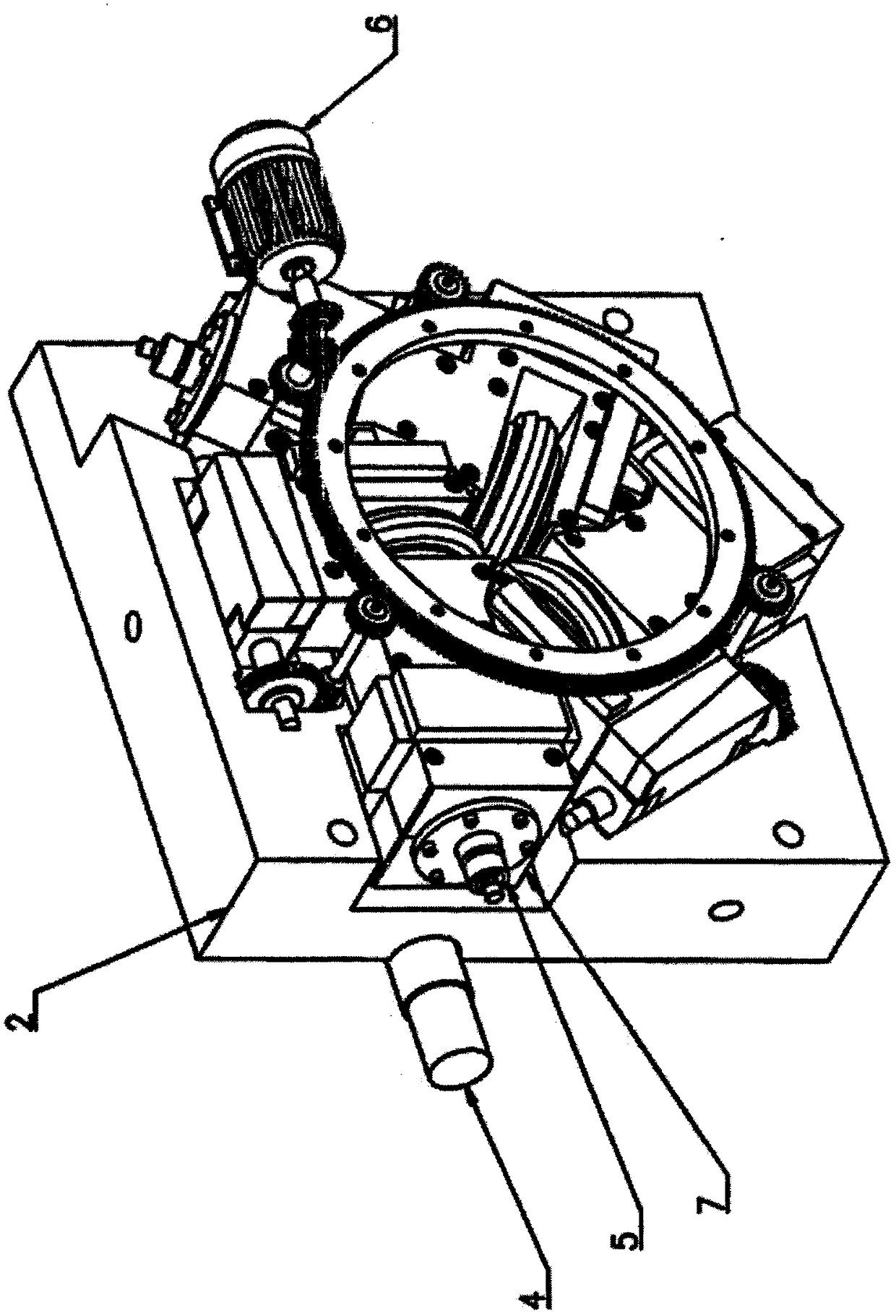

A two-stage lateral transmission three-roll rolling mill

A three-roll mill, drive-side technology, applied in metal rolling stands, metal rolling mill stands, driving devices for metal rolling mills, etc., can solve the problem that the three-roll mill roll gap cannot be adjusted, increase energy consumption, increase backup Rack etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The core of the present invention is to move the rolls perpendicular to the direction connecting the centers of the two transmission gears to adjust the roll gap, and in order to cooperate with this way of adjusting the roll gap, three roll chocks 7 that are designed and arranged to move perpendicular to the rolled piece, and Gap adjustment mechanism 6. Embodiments of the present invention are as Figure 7 As shown in middle a, when adjusting the roll gap, the roll 5 is perpendicular to the line connecting the center of the drive shaft 4, and moves a certain distance within the roll gap adjustment range, deviated from the line connecting the centers of the original two meshing gears, the gear of the roll 5 is in the new A new connection line is formed between the center point and the gear center of the transmission shaft 4. This connection line forms a right-angled triangle with the line connecting the original center line and the distance that the adjustment roll gap m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com