A method and device for screening and rewinding optical fiber to prevent take-up whipping

An anti-whiplash and optical fiber technology, which is applied in the field of optical fiber screening and rewinding to prevent take-up whipping, can solve problems such as abnormal use, machine rewinding, optical fiber collision damage, etc., achieve reasonable device design, increase suction port design, and prevent whipping damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

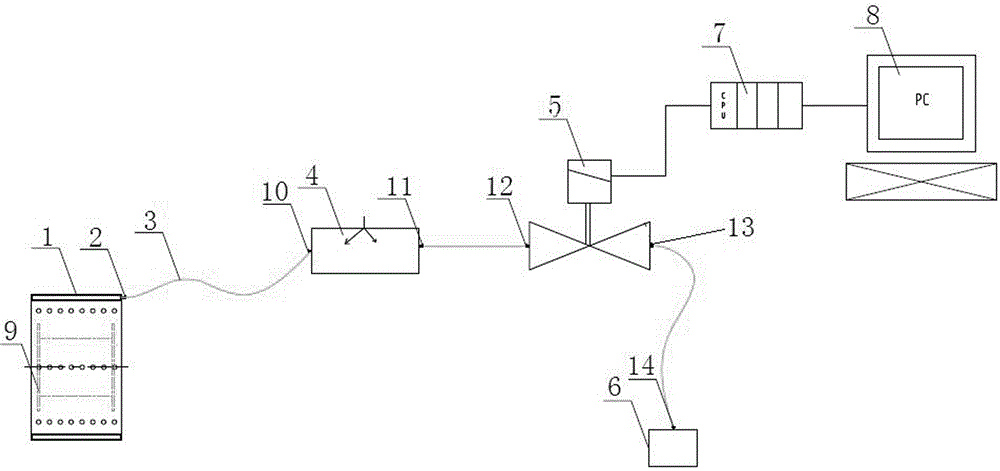

[0030] Refer to attached figure 1 , 2 A device for screening and rewinding an optical fiber to prevent whiplash from take-up includes an optical fiber anti-whiplash protective cover 1, a pipeline quick connector, a gas pipe, a vacuum pump 4, a solenoid valve 5, a PLC controller 7 and a main control computer 8.

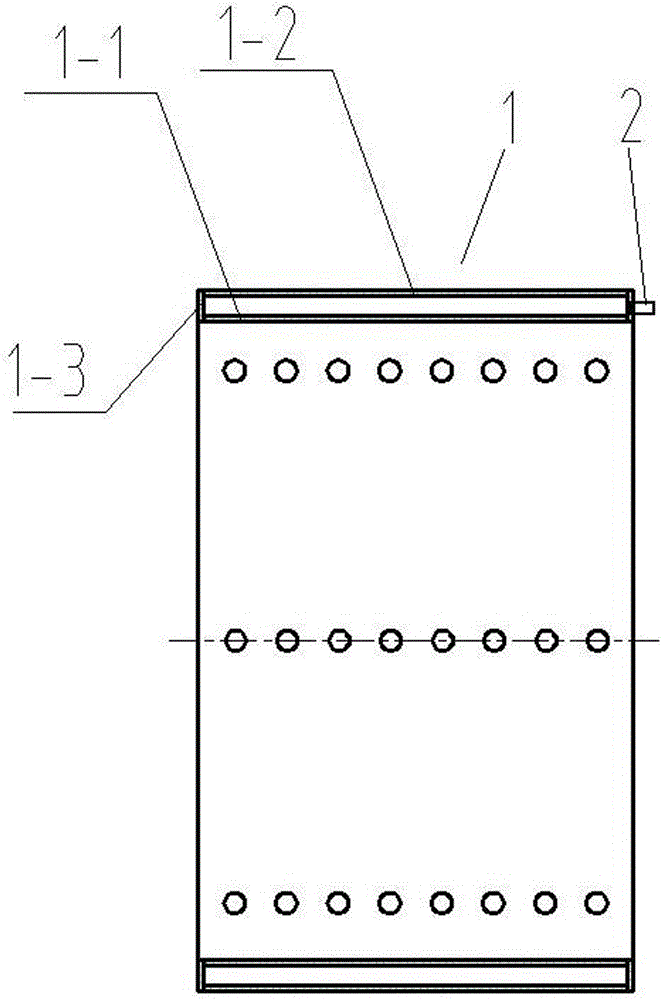

[0031] The optical fiber anti-whiplash protective cover 1 is installed on the main body bracket of the equipment. The optical fiber anti-whiplash protective cover 1 includes an inner protective cover 1-1, an outer protective cover 1-2, and a closed ring 1-3; the inner protective cover 1-1 is a circle Shaped protective cover, small holes are evenly distributed on the circular protective cover, the outer protective cover is a circular closed protective cover, the inner protective cover and the outer protective cover are sealed and welded by using the rings closed at both ends, the inner protective cover and the outer protective cover The middle of the protective cover i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com