Fan hub balancing structure

A technology of balancing structure and fan wheel, which is applied to components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc., can solve the overall strength effect of the top 11, the deformation of the sides, and the side 12. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

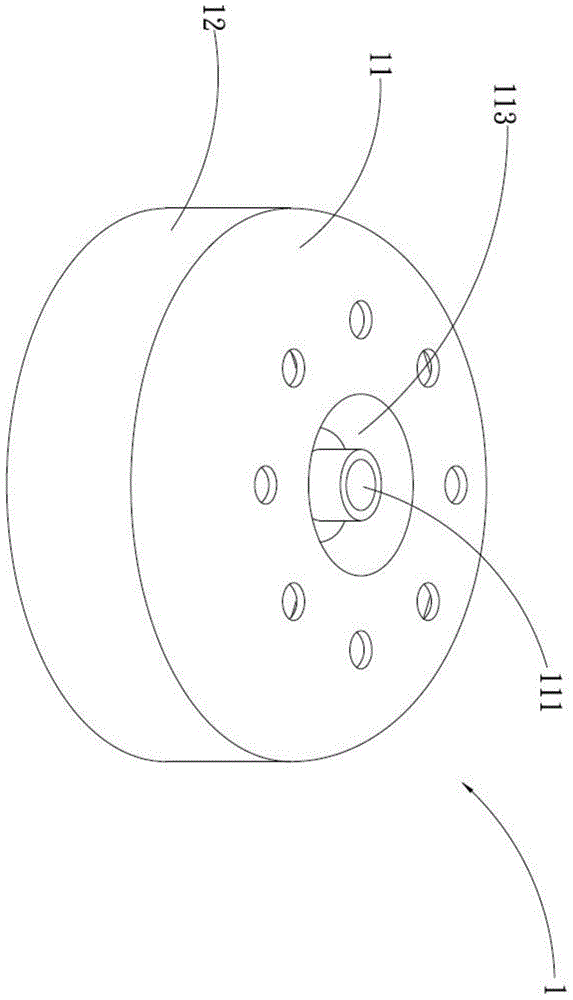

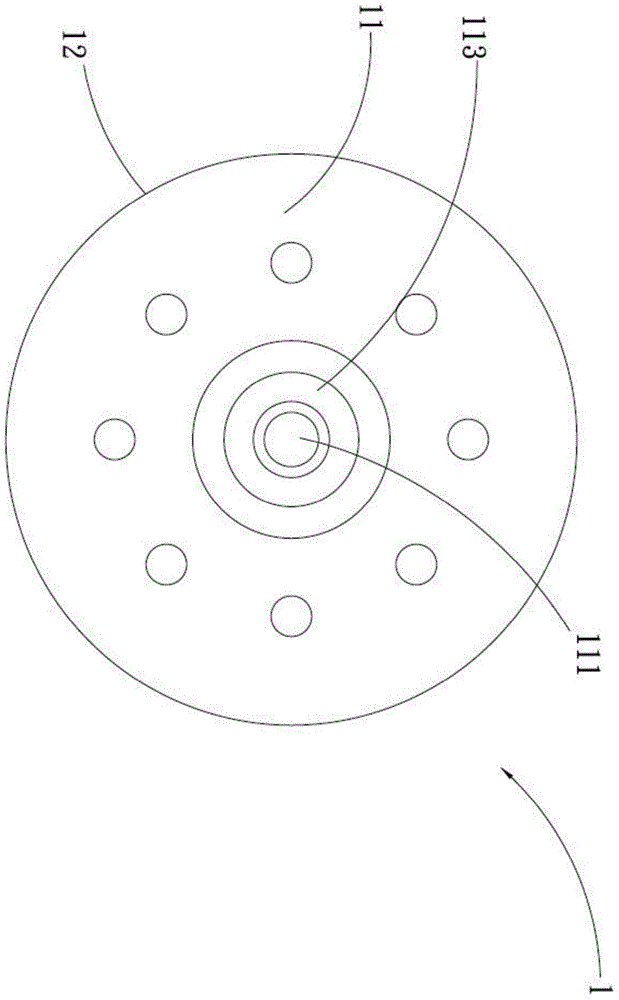

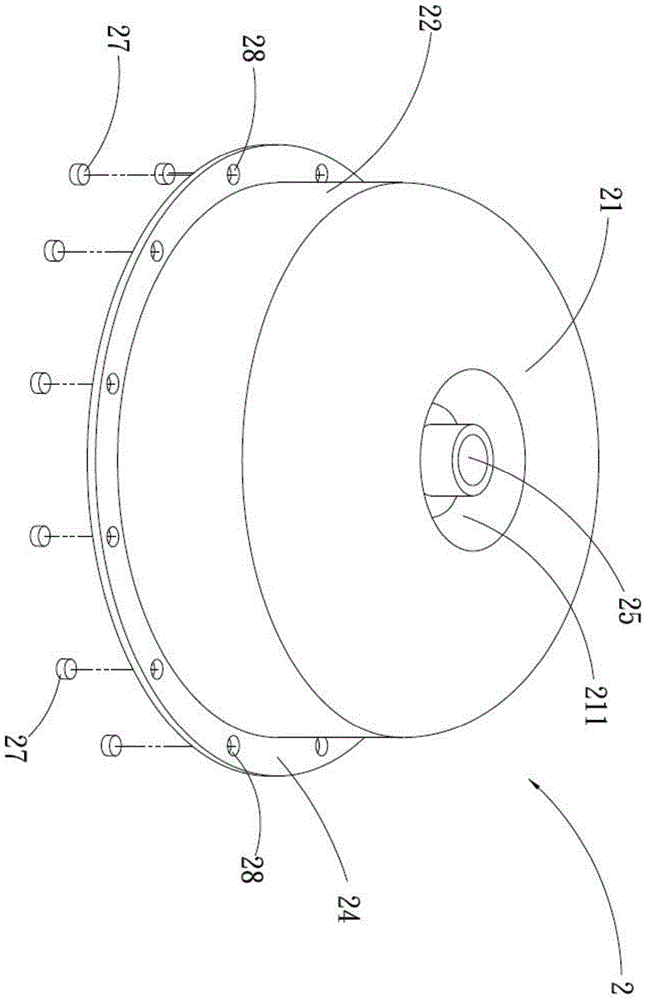

[0053] The present invention provides a fan hub balance structure, please refer to figure 2 , 3 , is a perspective view and a top view schematic diagram of the first preferred embodiment of the present invention, supplemented by referring to Figure 4 As shown; the fan hub balance structure includes a hub body 2, the hub body 2 is made of metal material (such as iron, aluminum), and the hub body 2 has a top 21, a side portion 22, a lip 24 and An opening 25, the opening 25 is opened at the center of the top 21, and it is used for inserting an axis 33, that is, one end of the axis 33 is plugged into the opening 25, and the other end is accommodated. In an accommodating space 26 of the hub body 2, the side portion 22 is provided with an upper end 221 and a lower end 222. It is formed by bending toward the outer side of the side portion 22 .

[0054] The above-mentioned upper end 221 is connected to the peripheral edge of the top 21, and the lower end 222 is connected to an en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com