Series hydrodynamic retarder

A hydraulic retarder and retarder technology, applied in the direction of liquid resistance brakes, brake types, mechanical equipment, etc., to achieve the effects of broadening the range of applicable models, ensuring normal operation, and avoiding insufficient assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

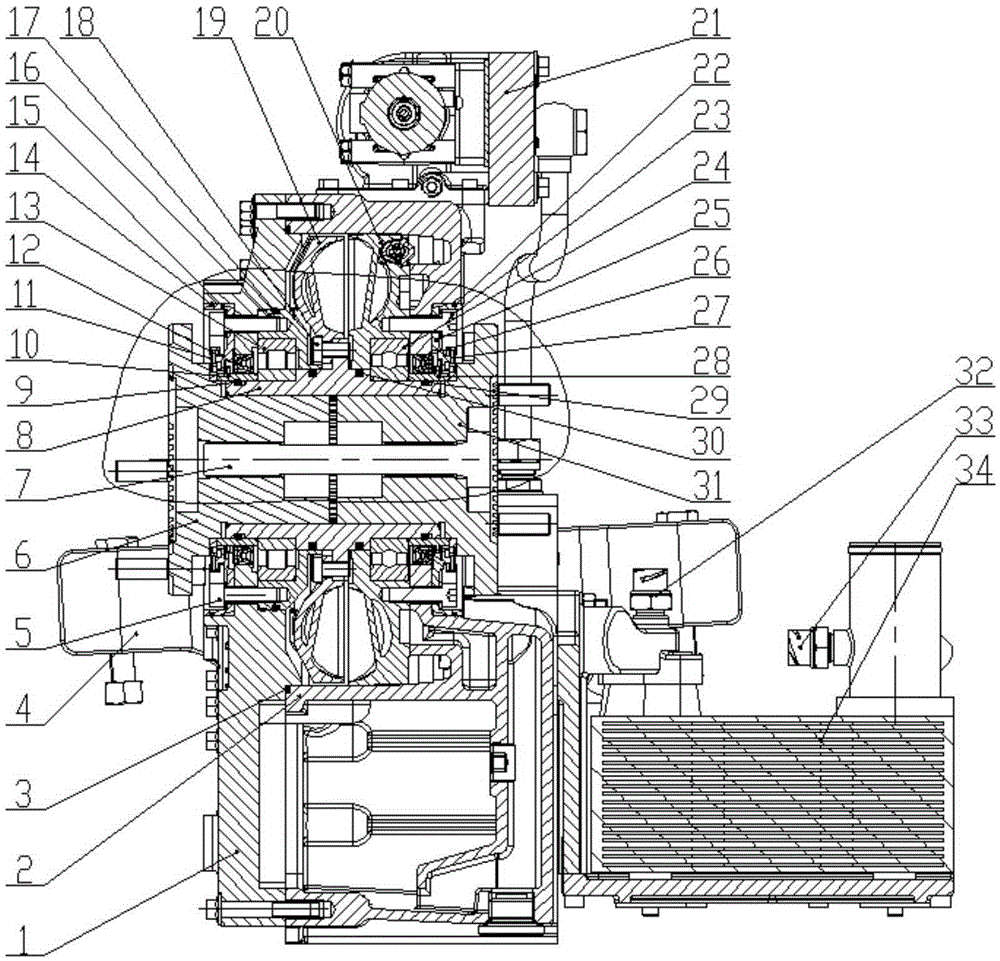

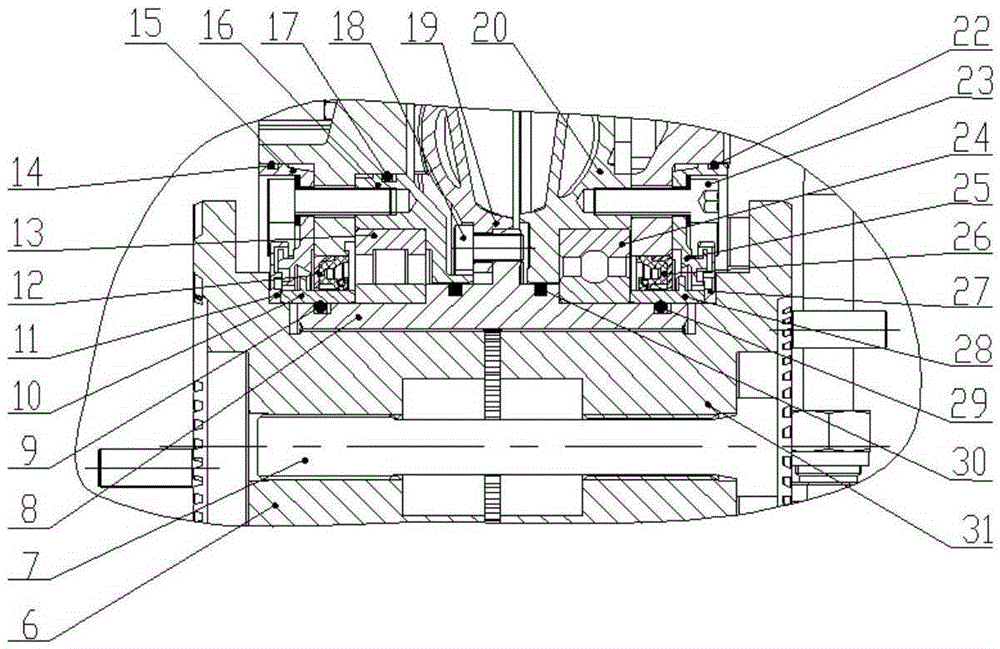

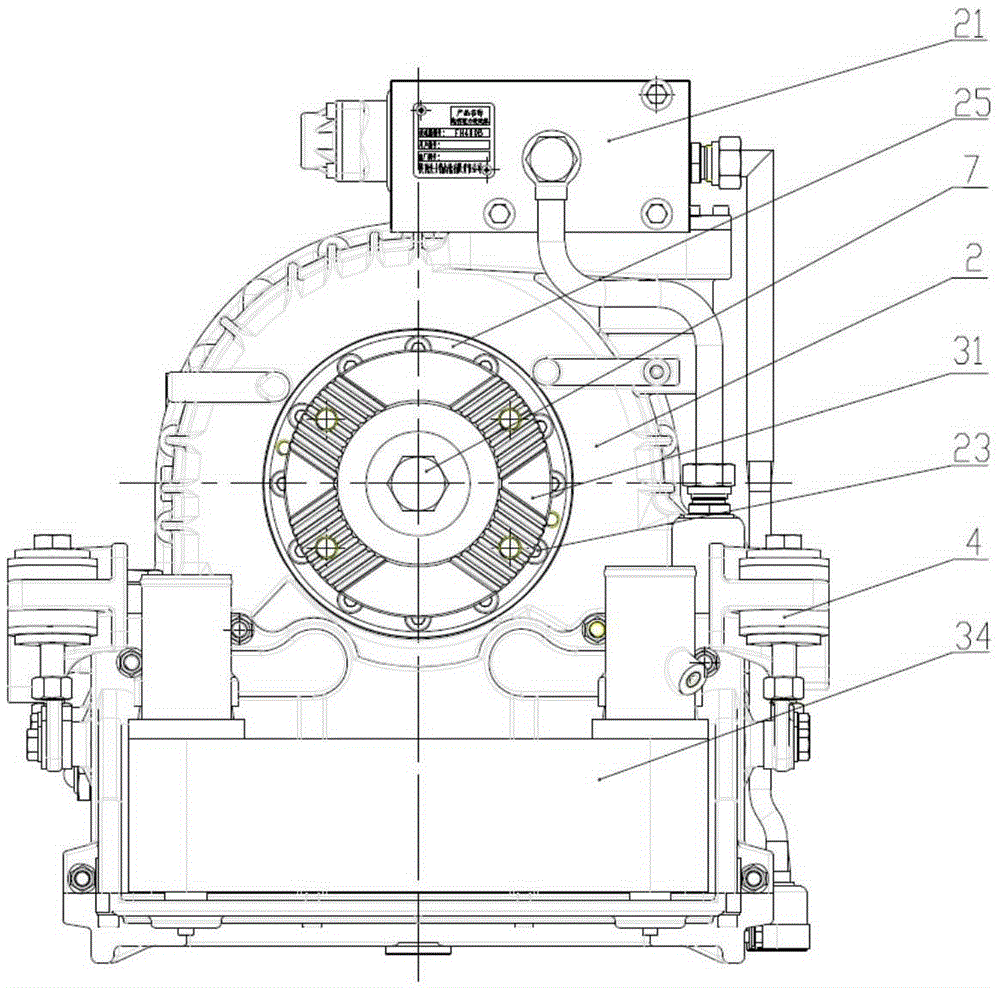

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0032] In the present invention, the series hydraulic retarder and the transmission are connected to transmit power through the retarder input flange 6 and the transmission flange, and direct connection or transitional connection can be adopted according to the actual situation during assembly. When there is interference in the assembly space, the installation position of the retarder can be adjusted between the second axle and the driving axle of the vehicle, which effectively avoids the problem of insufficient assembly space and broadens the range of applicable models of the tandem hydraulic retarder. Since the series hydraulic retarder is separated from the rear cover of the transmission and assembled independently, the partial structure of the retarder needs to be rearranged. The present invention fixes the retarder on the longitudinal beam by adding retarder conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com