A kind of notebook shell injection molding fixture

A notebook shell and jig technology, applied in the field of injection molding jig, can solve the problems of easy generation of burrs and long time, and achieve the effect of speeding up cooling molding and reducing product burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings of the specification.

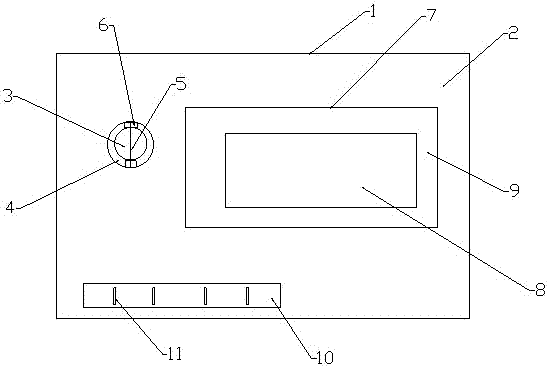

[0014] Such as figure 1 As shown, an injection molding jig for a notebook casing includes a treatment body surrounding a mold cavity 2. It is characterized in that the treatment body 1 is a frame structure, and the treatment body is provided with a first inlay block 3, and the second The outer side of an inlay block is wrapped by the lubricating part 4, the first inlay block and the lubricating part form a whole, and the treatment body further includes a recessed part 10 on which a protrusion 11 is provided.

[0015] The center of the whole formed by the first inlaid block and the lubricating part is provided with a dividing line 5, which divides the whole into two semicircular structures, and the two semicircular structures are arranged in the semicircular structure. The bolt structures 6 of the edges are connected to each other.

[0016] A second inla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com