A precision injection-blow mold for the production of cosmetic packaging bottles and its production method

A production method and technology for packaging bottles, which are applied to precision injection-blow molds for cosmetic packaging bottle production and their production fields, can solve the problem that packaging preforms are easily adhered to stretching rods, inconvenient to manufacture packaging bottles, and difficult to fall off packaging preforms. problem, to achieve the effect of promoting cooling and forming, easy to make and easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

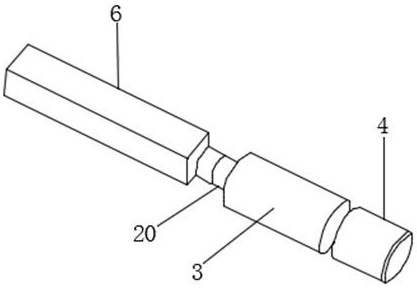

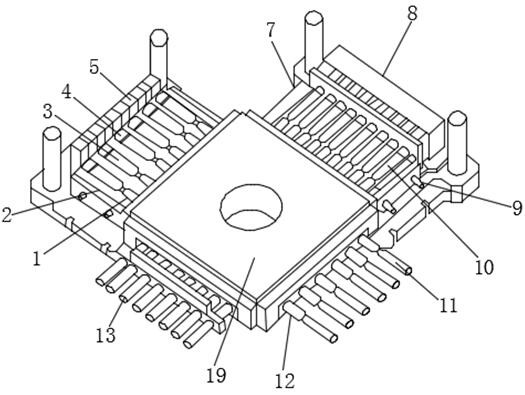

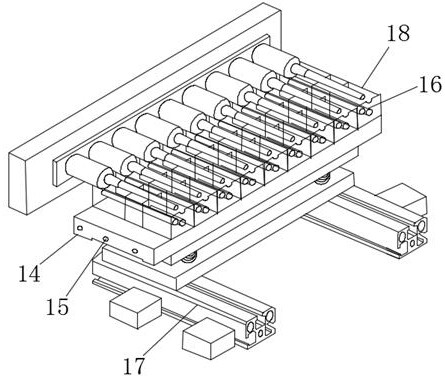

[0024] refer to Figure 1-3 , a precision injection blow mold for the production of cosmetic packaging bottles, comprising a central transfer mold 19, an injection molding mechanism, a blowing mechanism, and a cooling mechanism are respectively arranged around the center transfer mold 19, and the injection molding mechanism includes an injection mold seat 7, an injection mold seat 7 is provided with a plurality of fixing bolts 9, and the injection mold seat 7 is arranged on the right side wall of the center transfer mold 19, and the upper end surface of the injection mold seat 7 is provided with a plurality of blank grooves, and each blank groove is provided with There are injection molding tubes 10, and the opening end of each injection molding tube 10 is fixedly installed on the injection molding cavity 8. The injection molding tubes 10 are sealed, and the shape of the injection molding tubes 10 matches the shape of the blank groove. Mold seat 2, blowing mold seat 2 is arran...

Embodiment 2

[0031] refer to Figure 1-3, a precision injection blow mold for the production of cosmetic packaging bottles, comprising a central transfer mold 19, an injection molding mechanism, a blowing mechanism, and a cooling mechanism are respectively arranged around the center transfer mold 19, and the injection molding mechanism includes an injection mold seat 7, an injection mold seat 7 is provided with a plurality of fixing bolts 9, and the injection mold seat 7 is arranged on the right side wall of the center transfer mold 19, and the upper end surface of the injection mold seat 7 is provided with a plurality of blank grooves, and each blank groove is provided with There are injection molding tubes 10, and the opening end of each injection molding tube 10 is fixedly installed on the injection molding cavity 8. The injection molding tubes 10 are sealed, and the shape of the injection molding tubes 10 matches the shape of the blank groove. Mold seat 2, blowing mold seat 2 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com