Suspension bracket dynamic impact test tool

A suspension bracket and impact test technology, applied in the field of suspension bracket dynamic impact test tooling, can solve the problems of reducing the collision simulation accuracy and simulation simulation of the whole vehicle, save design time and development cost, ensure reliability, and improve collision Simulate the effect of simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is a suspension bracket dynamic impact test tool, which is mainly used for the simulation test of a single suspension bracket in the early stage of product development, so as to obtain the structure of the suspension bracket through the impact failure deformation of a single suspension bracket in the collision test mechanical properties.

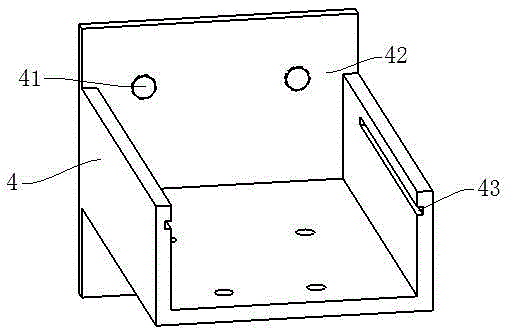

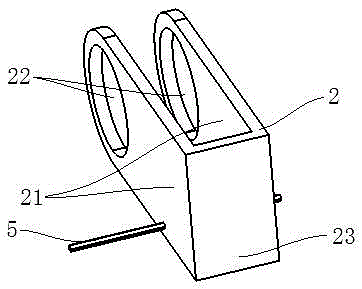

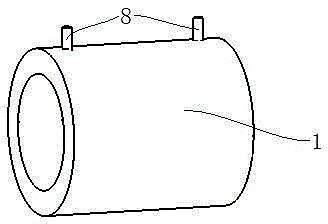

[0024] A suspension bracket dynamic impact test tooling includes an impact transmission shaft 1, an impact bearing structure 2, a suspension bracket 3, a suspension bracket mounting seat 4, and a limit structure; the structure of the suspension bracket 3 is as follows: figure 1 As shown, on the suspension bracket 3, a mounting hole 31 that cooperates with the impact transmission shaft 1 is reserved, and a base 32 that is installed and matched with the suspension bracket mounting seat 4 is provided at the bottom of the suspension bracket 3; the suspension bracket mounting seat 4. The cross section is in the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com