Method for determining transient temperature of air pre-cooled and pre-heated concrete aggregates

A technology of concrete aggregate and transient temperature, applied in the fields of heat transfer and engineering heat transfer, can solve the problems of low calculation accuracy, failure to reflect the real situation of air temperature changes, calculation errors and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

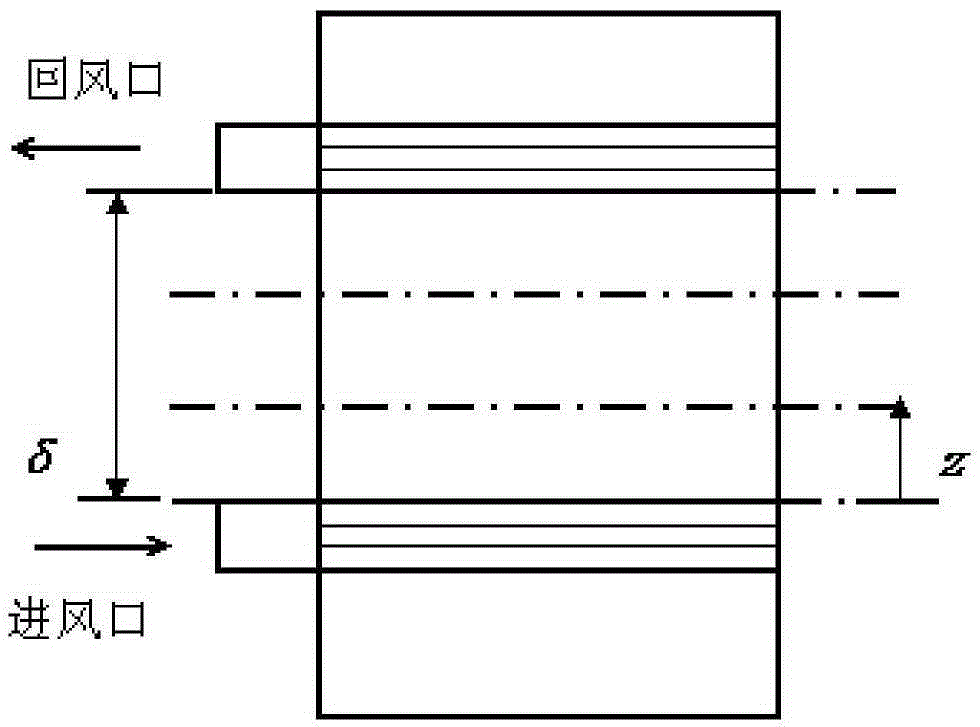

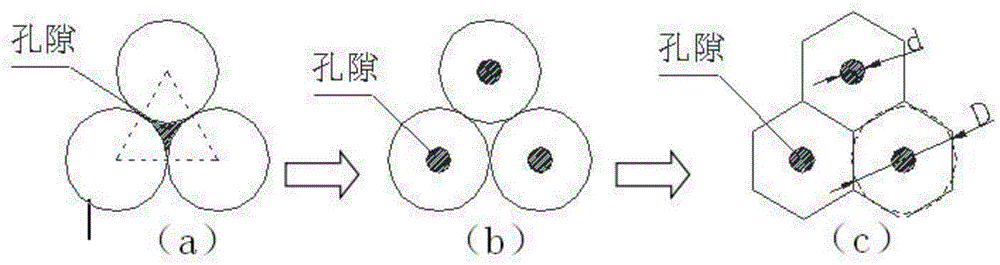

[0084] In order to overcome the low calculation accuracy and waste of energy in the existing determination methods, the present invention provides a method for determining the transient temperature of air precooled and preheated concrete aggregates. The present invention considers the effective thermal conductivity of aggregates + void porous media The influence of air convection must be taken into account. During the process of air precooling and preheating aggregates, the aggregates are naturally piled up in the silo, forming a co-existing combination with the void, so it can be considered that the aggregates in the silo and The voids form a porous medium. The convective heat transfer process between the aggregate in the silo and the air in the gap can be regarded as an unsteady heat conduction process produced by the convective heat transfer of the aggregate + void porous medium at the air inlet section, so that the error is reduced, and the calculated The temperature is mo...

Embodiment 2

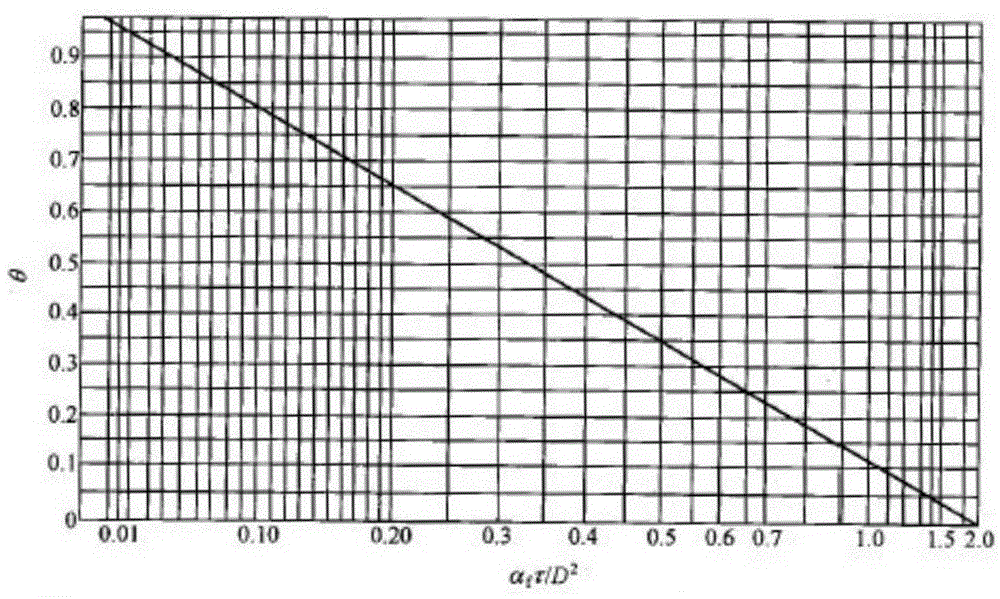

[0095] On the basis of embodiment 1, in the present embodiment, fitting coefficient A, B, C, Fo in step 3) * , the specific calculation is as follows:

[0096] A=A'·Bi+A"

[0097] B=B'·Bi+B"

[0098] C=C'·Bi+C"

[0099] A ′ = [ - 0.0813 · ( Z δ ) 2 - 0.0202 · ( Z δ ) - 0.016 ] · δ D e + ( 0.0448 · ( Z δ ) 2 - 0.0658 · ( Z...

Embodiment 3

[0129] Based on the basis of embodiment 1, the calculation process of each step in the present embodiment is as follows:

[0130] (1) Calculation module of thermal and physical properties of porous media

[0131] It is known that the void ratio ε of the stockpiled material in the silo, the cross-sectional wind speed u of the empty silo, the diameter d of the aggregate, and the thermal conductivity λ of the aggregate s , the aggregate density ρ s , the specific heat of the aggregate c s , the density of air ρ a , the specific heat of air c a , the thermal conductivity of air λ a , the Prandtl number Pr of air a , the dynamic viscosity of air μ a .

[0132] Wind speed at aggregate voids: u kx = u ϵ - - - ( 9 )

[0133] Equivalent diameter of void: d k x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com