Propofol composition for injection and preparation method thereof

A technology of propofol and its composition, which is applied in the field of propofol composition for injection and its preparation, and can solve the problems of endangering health, producing toxic substances and carcinogens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Composition prescription:

[0038] Propofol 5.0kg

[0039] Soybean oil 50kg

[0040] Lecithin 6.0kg

[0041] Glycerin 12.5kg

[0042] Appropriate amount of sodium hydroxide

[0043] Water for injection up to 500L.

[0044] Preparation:

[0045] (1) Empty tank and pipeline treatment: Use 0.01-5% EDTA solution to clean the pipeline and liquid distribution tank, and repeatedly remove oxygen in the pipeline and tank through nitrogen-vacuum mode to make the oxygen content less than 1%;

[0046] (2) Oil phase preparation: Inhale the oil for injection into the oil phase tank by vacuum feeding, continue vacuuming to remove the air suspended in the oil phase, heat to 60 degrees, put in emulsifier under nitrogen protection, and stir evenly;

[0047] (3) Water phase preparation: Add appropriate amount of water for injection in a vacuum state, the water temperature is 70 degrees, the vacuum reduces the dissolved oxygen in the water to below 1ppm, and then puts in the prescrib...

Embodiment 2

[0053] Composition prescription:

[0054] Propofol 5.0kg

[0055] Soybean oil 50kg

[0056] Lecithin 6.0kg

[0057] Glycerin 12.5kg

[0058] Appropriate amount of sodium hydroxide

[0059] Water for injection up to 500L.

[0060] Preparation:

[0061] (1) Empty tank and pipeline treatment: traditional nitrogen filling process;

[0062] (2) Oil phase preparation: Inhale the oil for injection into the oil phase tank by vacuum feeding, heat to 60 degrees, add emulsifier, stir evenly, and protect the whole process with nitrogen. After online dissolved oxygen monitoring, the dissolved oxygen in the oil phase is about 7ppm ,

[0063] (3) Preparation of water phase: add appropriate amount of water for injection under vacuum state, water temperature is 70 degrees, put in the prescribed amount of glycerin and other water-soluble components under nitrogen protection, and the dissolved oxygen in the water phase is about 7ppm through online dissolved oxygen monitoring.

[0064] (4...

Embodiment 3

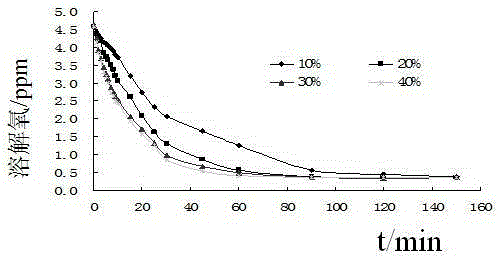

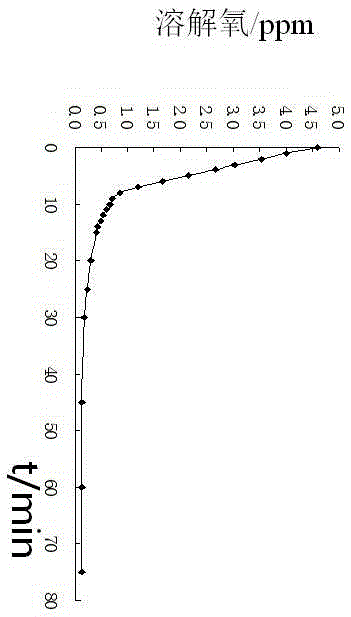

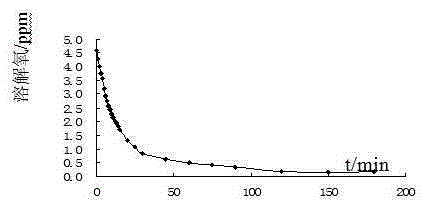

[0087] Oxygen removal process

[0088] thermal oxygen removal

[0089] Add 500L of water for injection (water temperature 78°C) into the liquid mixing tank, heat the water for injection to boiling, start the self-circulation pump and time it, and record the online dissolved oxygen detection data. The measurement results are shown in figure 1 .

[0090] Conclusion: It can be seen from the above data that as the heating and boiling time increases, the amount of dissolved oxygen in water gradually decreases. Under normal pressure, 500L of water for injection needs to be heated and boiled for more than 120 minutes, so that the dissolved oxygen can be maintained at about 1ppm. It can be seen that although the theoretical water temperature is 100°C, the solubility of oxygen in water is 0ppm. However, there is a reversible dynamic equilibrium between the dissolved oxygen in the water and the gaseous oxygen in the liquid distribution tank, and they will be converted into each other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap