Anti-piercing and anti-gas-leakage tire

A tire and anti-puncture technology, which is applied in the field of vehicle tires, can solve problems such as bursting and deflation, and achieve the effects of increasing service life, reducing driving accidents, failures, and accident rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

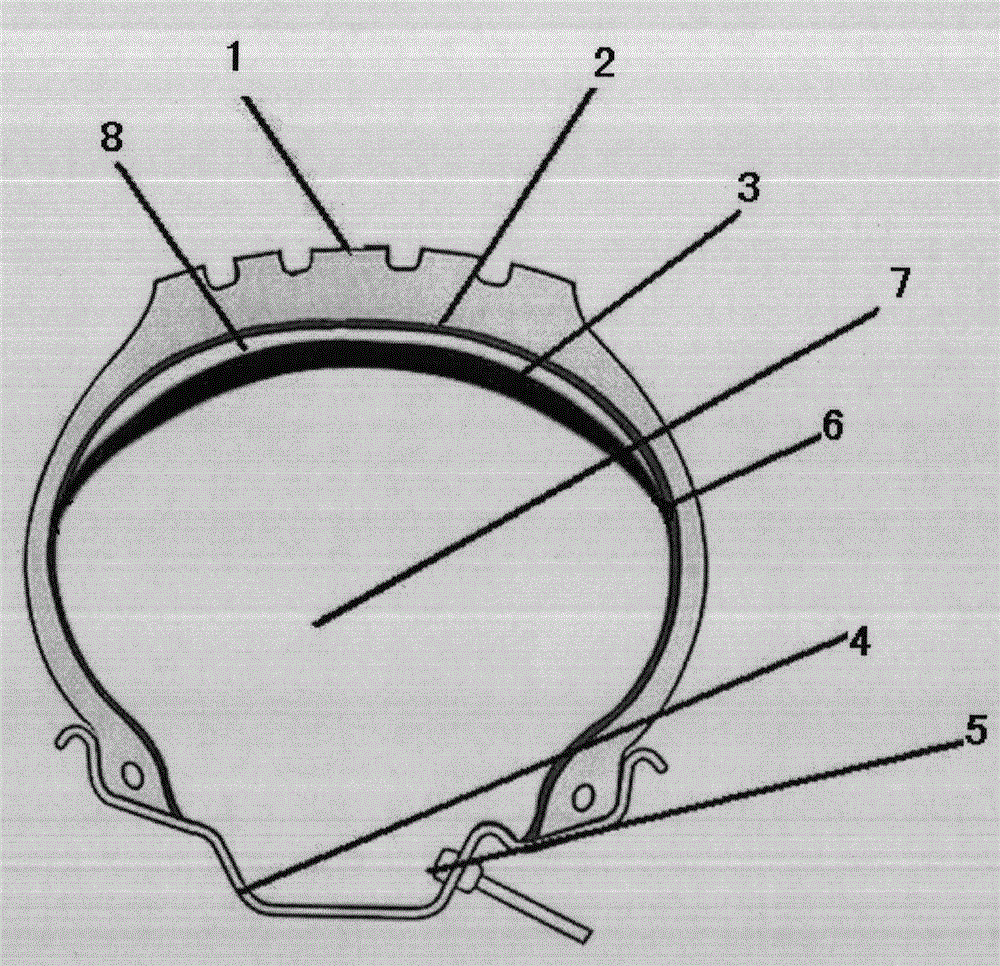

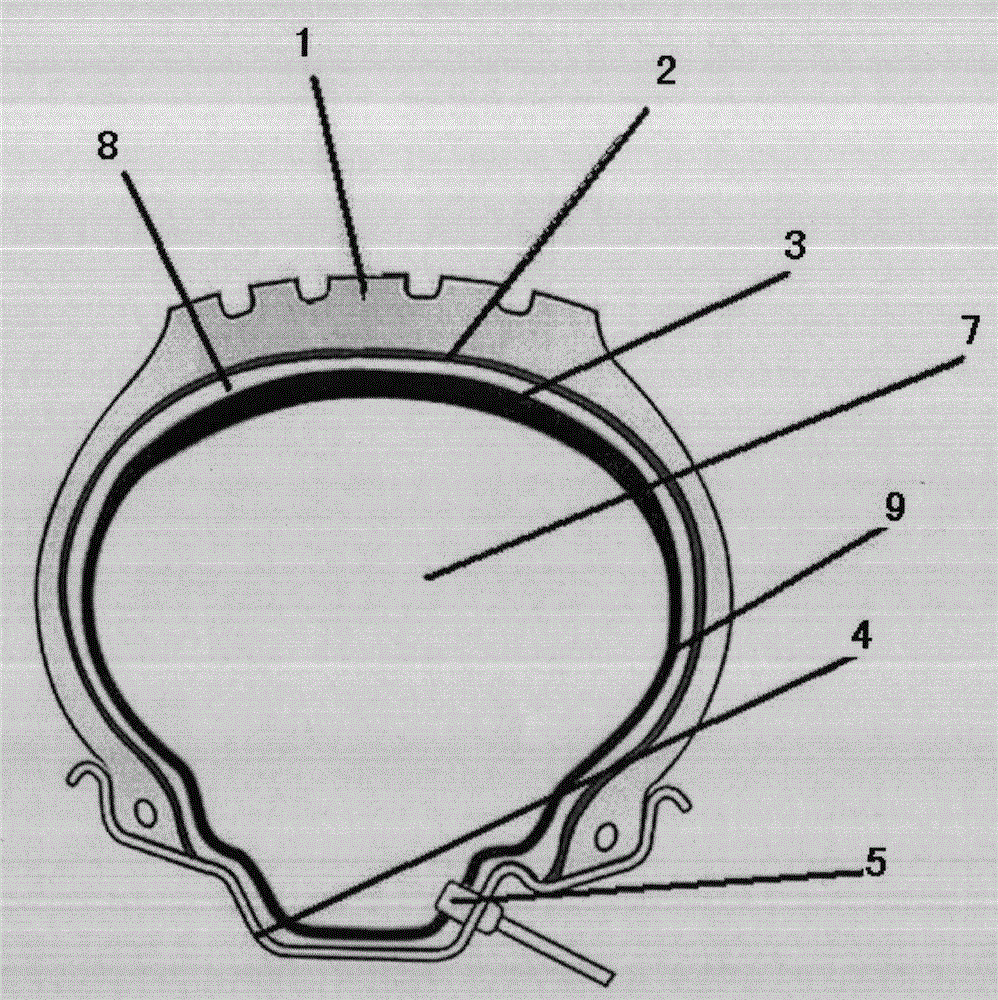

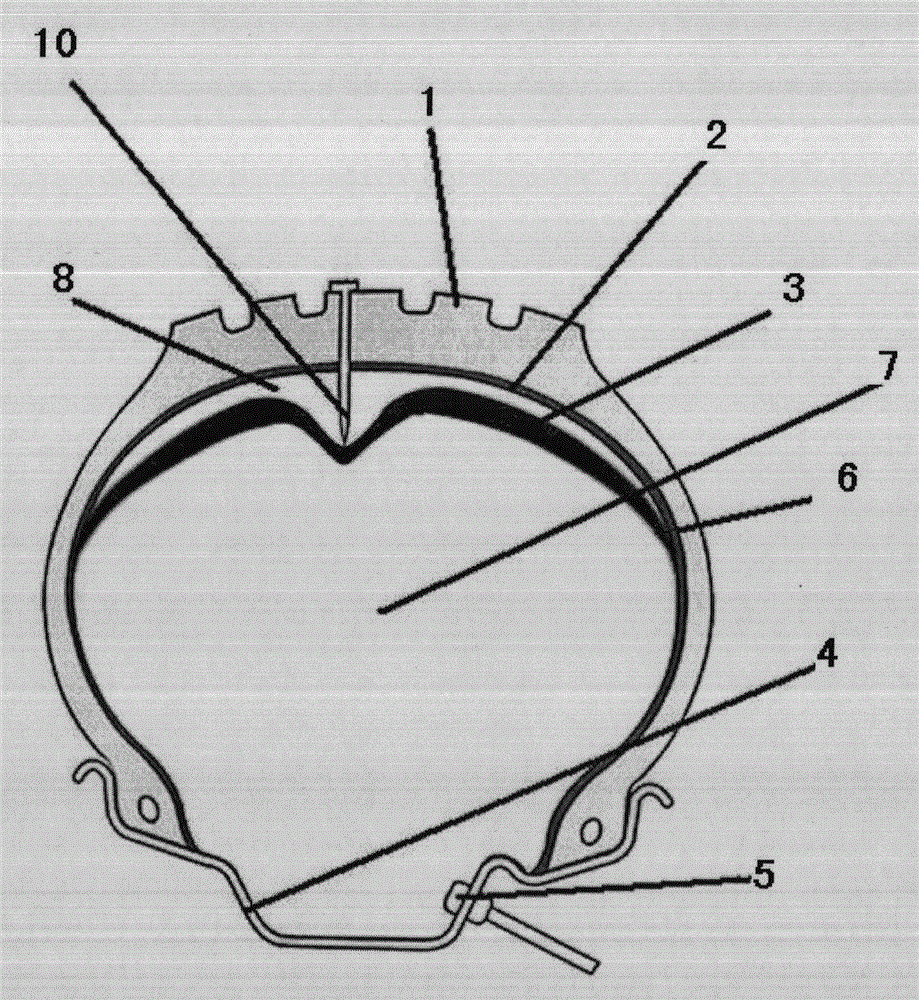

[0026] figure 1 Among them, both sides of the circumferential edge of the anti-tie layer 3 are airtightly combined with the tire inner layer 2 to form a linear airtight joint 6, and a gas isolation zone 8 is formed between the anti-tack layer 3 and the inner layer 2 of the tire; After the tire is inflated, an airtight gas high pressure zone 7 is formed between the hub 4 and the anti-puncture layer 3 . Because both sides of the circumferential edge of the anti-tie layer 3 are airtightly combined with the tire inner layer 2, the anti-tack layer 3 is propped up by the high-pressure gas so that it is close to the tire inner layer 2. The anti-punching layer 3 isolates the isolation zone 8 from the gas high-pressure zone 7 by air, that is, they cannot breathe through each other. It should be noted that, in order to be suitable for military vehicles such as off-road military vehicles, armored vehicles, and tanks to prevent bullets and bomb explosives from piercing tires from the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com