Manipulating handle of snowmobile

A technology for manipulating handlebars and snowmobiles, which is applied to vehicle components, superstructures, subassemblies of superstructures, etc., and can solve problems such as the inability to adjust the length of the handlebars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

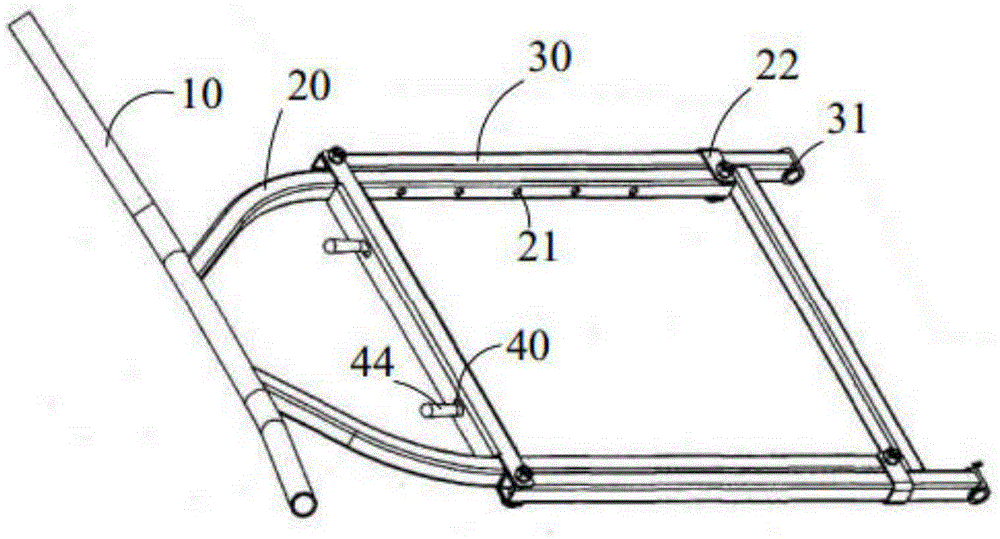

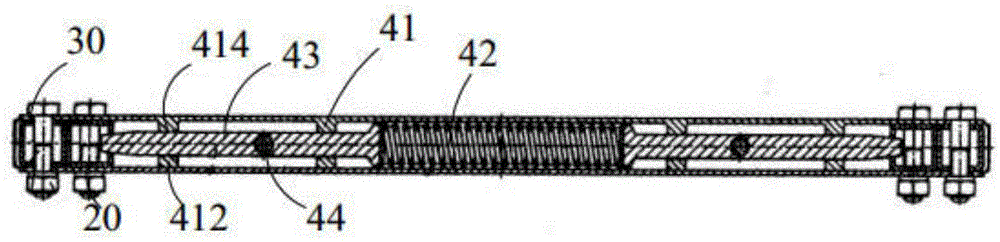

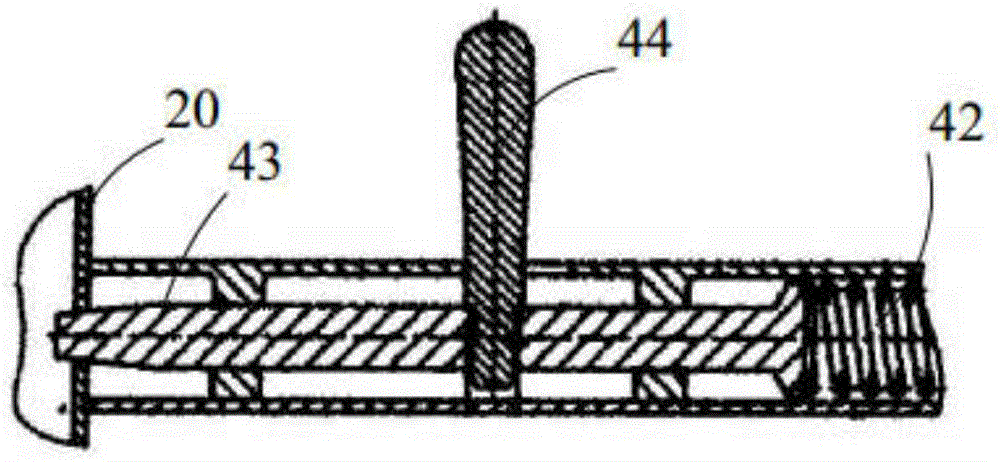

[0019] 10 is the handle, 20 is the adjusting rod, 30 is the fixed frame, 40 is the positioning assembly, 21 is the positioning hole, 41 is the guide positioning piece, 42 is the spring, 43 is the locking pin, 44 is the rocker, 410 is the main board, 411 is the Bottom plate, 412 is a guide positioning block, 413 is a mounting hole, 414 is a through hole, 415 is a reinforcing rib, 441 is a hemispherical segment, 442 is a circular table segment, 443 is a cylindrical segment, 444 is a threaded rod, 22 is a sliding sleeve, 31 is a Rotate the joint.

[0020] see Figure 1 to Figure 3 , the snowmobile handle includes a handle 10 , an adjustment rod 20 , a fixed frame 30 and a positioning assembly 40 . One end of the adjustment rod 20 is fixedly connected with the handle 10 , the other end of the adjustment rod 20 is movably connected with the fixed frame 30 , and the positioning assembly 40 is arranged in the fixed frame 30 and is connected with the adjustment rod 20 by engaging. I...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap