Wall panel automatic installation vehicle

A technology for automatic installation and wall panels, which is applied in construction, building construction, and processing of building materials. It can solve the problems of large space requirements for prefabricated wall panels, limited installation space height, height restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

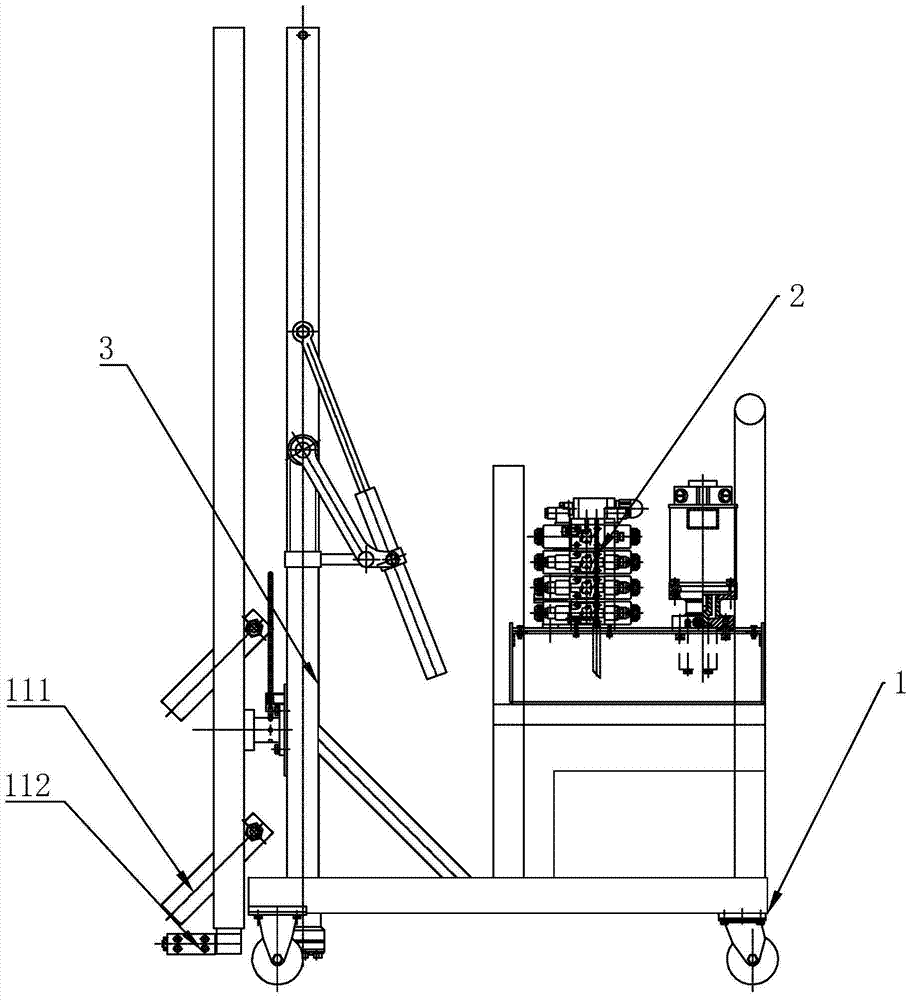

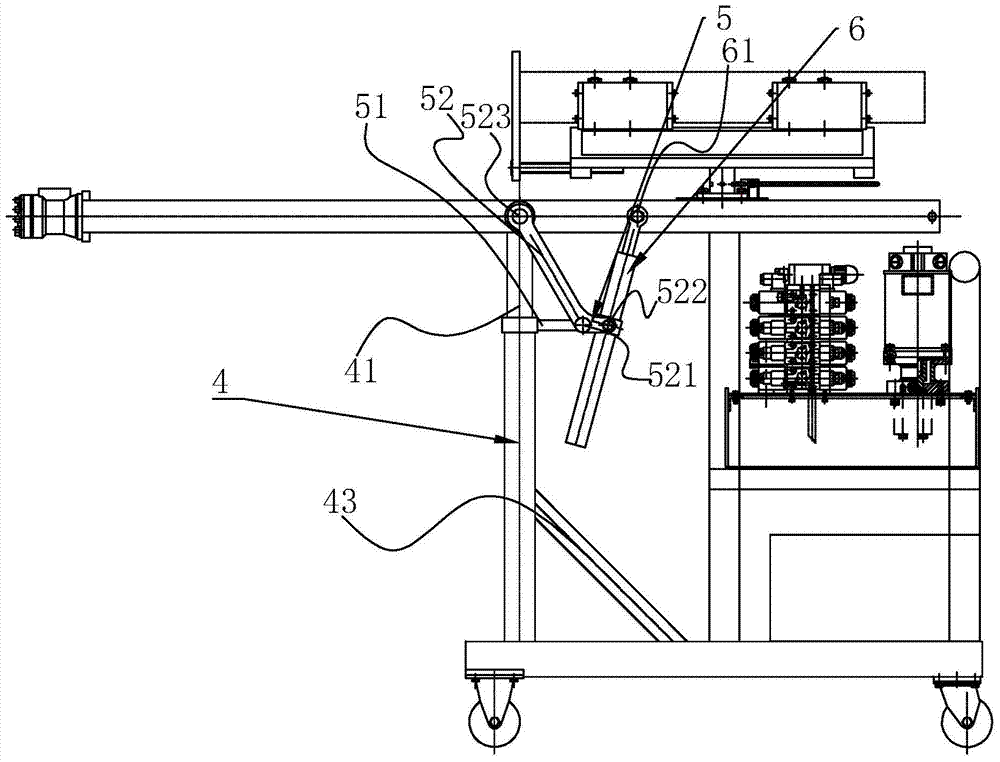

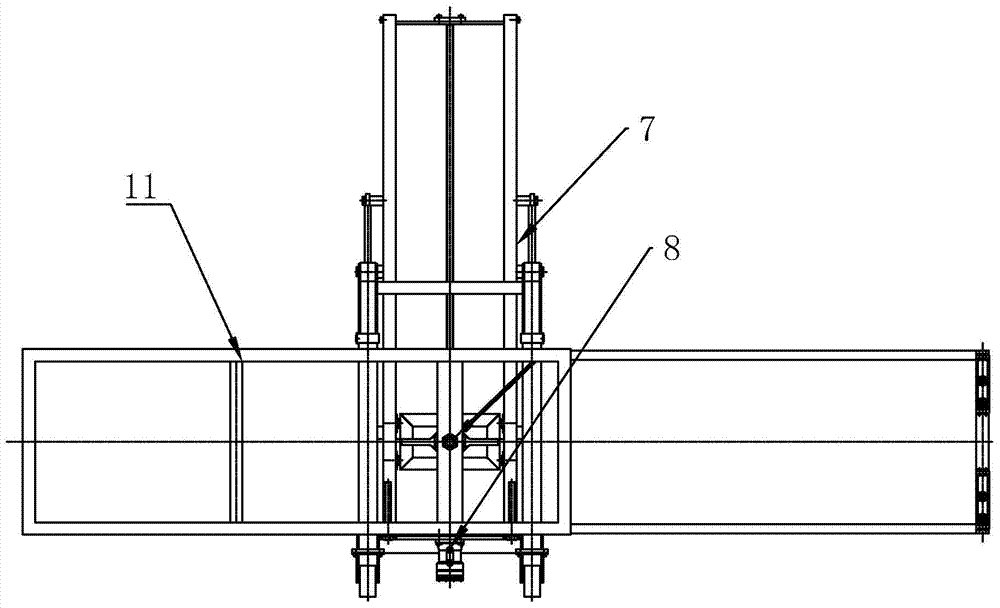

[0049] refer to Figure 1 to Figure 14 The embodiment of the automatic wall panel installation vehicle of the present invention will be further described.

[0050] An automatic wall panel installation vehicle includes a vehicle body 1 , a control station 2 and an action unit 3 . The car body 1 is provided with a bracket 4, and the action unit 3 is fixed to the car body 1 through the connection with the bracket 4. The bracket 4 includes two uprights 41, a cross brace 42, and is obliquely fixed on the upright 41 and the car body 1. Between the reinforcing ribs 43, a group of link mechanisms 5 are arranged on each column 41, and the link mechanism 5 includes a column 41 vertically fixed on the vehicle body 1, and a strut 511 sleeved on the column 41. One end of the support rod 511 is connected to the column 41, and one end is rotatably connected to a curved rod 522. The curved rod 522 includes an inflection point 521, a first rotation pair 522 and a second rotation pair 523, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com