Garbage incinerator

A technology of waste incinerator and incinerator, which is applied in the directions of incinerator, combustion method, combustion type, etc., can solve the problems of energy waste and incineration heat utilization, etc., and achieve good energy saving, high energy utilization rate and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

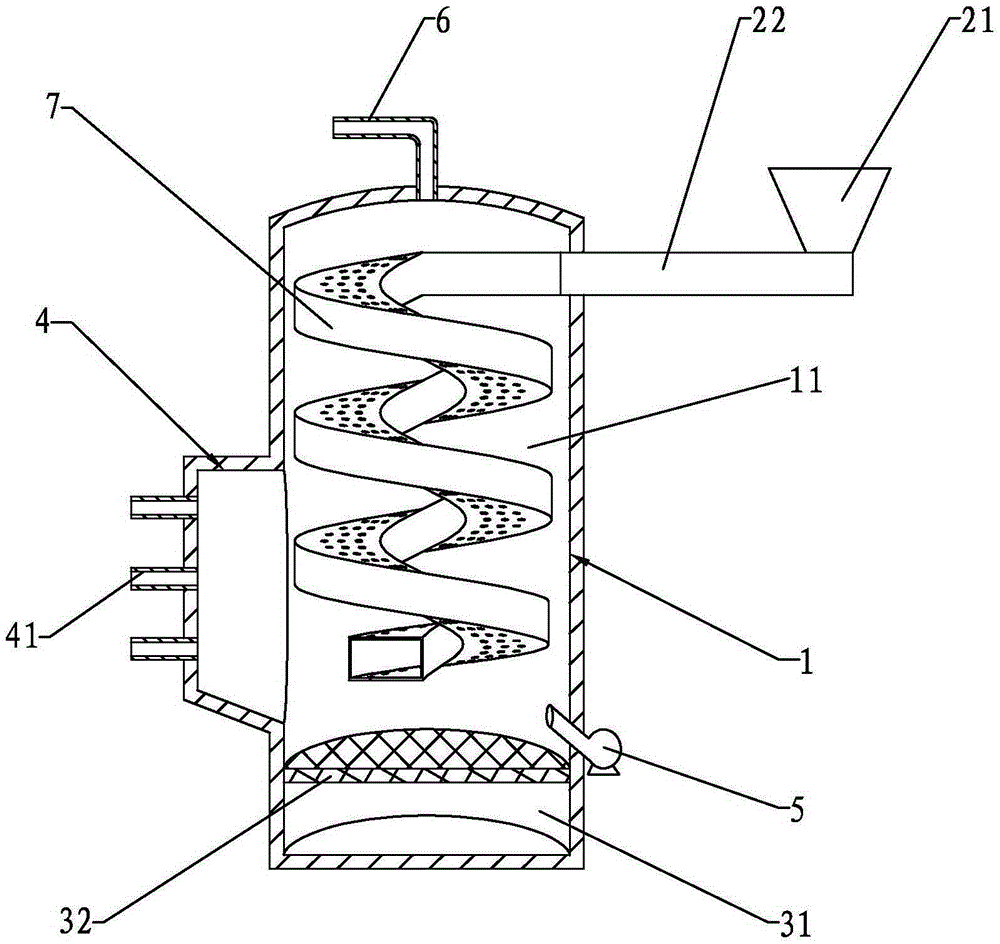

[0018] Such as figure 1 As shown, the garbage incinerator includes a furnace body 1 provided with an incineration chamber 11, a feeding part arranged on the upper part of the incineration chamber 11, a discharge part arranged at the bottom of the incineration chamber 11, and a fire storage chamber arranged on the side of the furnace body 1 4. There is a communication part between the fire storage chamber 4 and the incineration chamber 11, and the lower part of the furnace body 1 is provided with a fan 5 whose air outlet faces the communication part. The fan 5 blows part of the flame in the incineration chamber 11 into the fire storage chamber 4. Since this part of the flame is relatively violent and difficult to control, the fire storage chamber 4 can be used as a buffer device to convert it into a controllable flame, and then from the fire storage chamber Some fire outlets 41 on the 4 output.

[0019] The feeding part includes a feeding hopper 21 and a screw conveying device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com