Integrated measurement instrument of inner-ring large flange of tapered roller bearing

A technology of tapered roller bearings and comprehensive measuring instruments, which is applied in the field of comprehensive measuring instruments, can solve the problems that the measurement of angle and linearity cannot be combined into one, cannot be detected on the processing site, and the accuracy of dimension transmission is low, so as to achieve measurement accuracy High, achieve on-site quantitative detection, repeatable and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

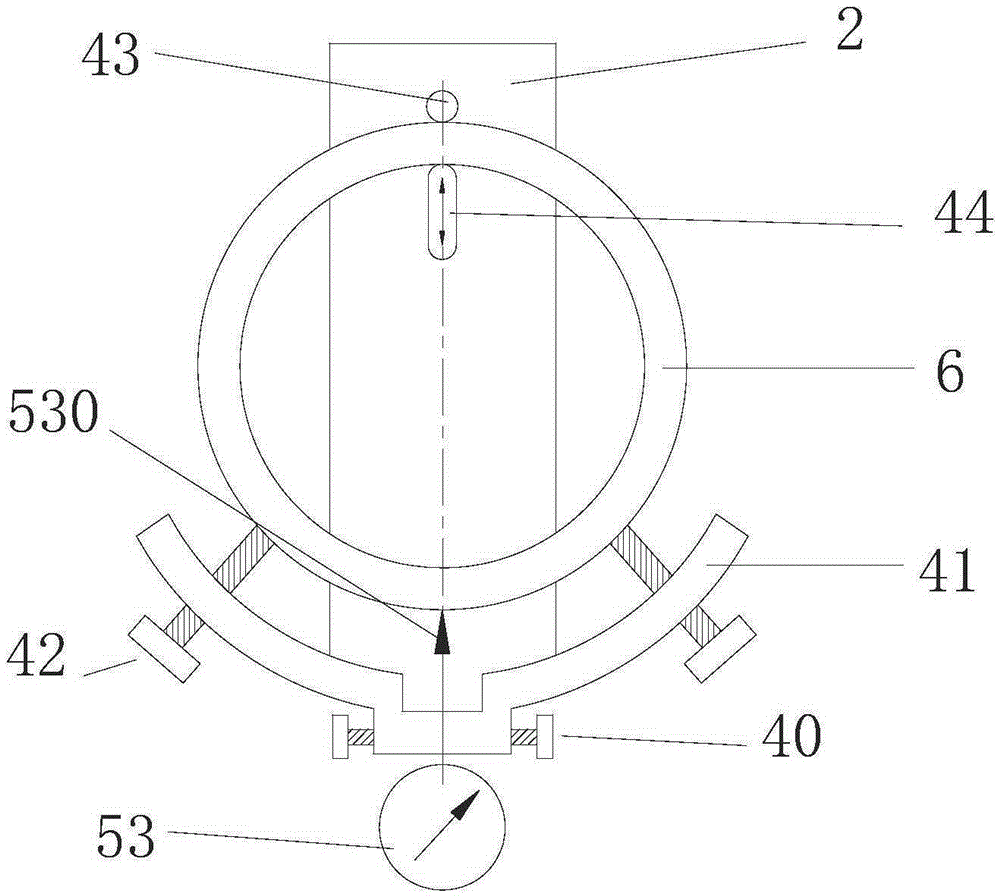

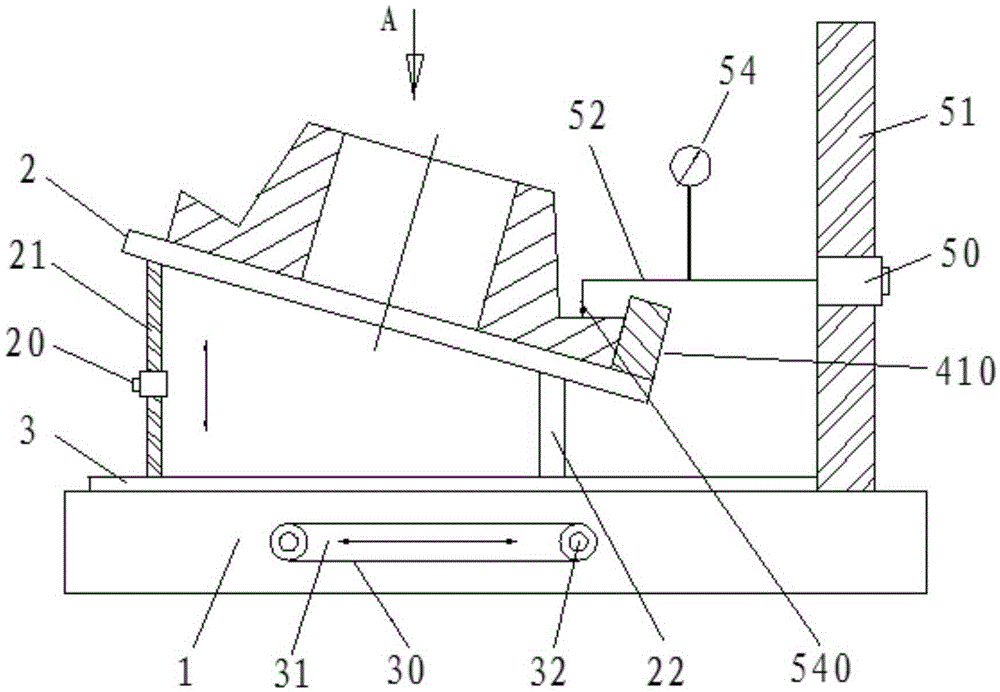

[0028] see Figure 1 to Figure 3 , The comprehensive measuring instrument of the large rib of the tapered roller bearing of the present invention includes a base 1, a workbench 2, a workpiece mounting mechanism and a measuring mechanism.

[0029] A Y guide rail 3 is installed on the upper end surface of the base 1, and a Y direction locator 30 is provided on the front end surface of the base 1; The chute 31 on the front end surface of the seat 1 and the handle 32 inserted in the chute 31 and vertically connected with the slide block.

[0030] The workbench 2 is installed on the slide block on the Y guide rail 3 through an adjustable-length movable foot 21 and a fixed foot 22. The movable foot 21 is a stud structure and is provided with a Z-direction locator 20, so that the workbench 2 can Adjust the tilt angle.

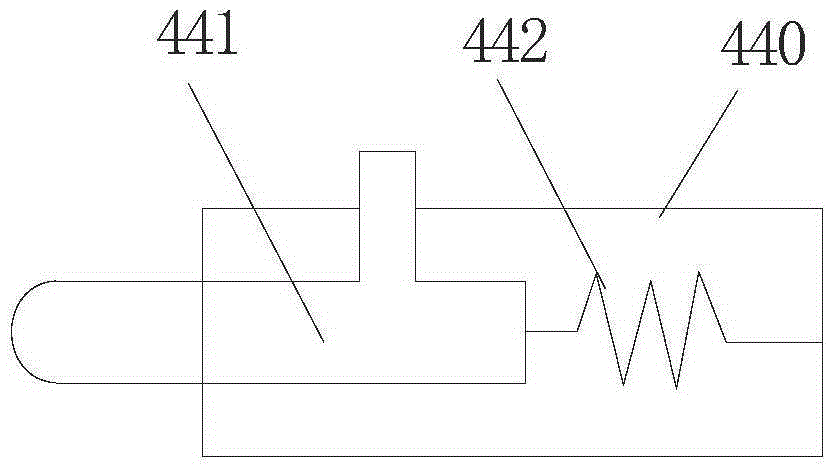

[0031] The workpiece positioning mechanism includes a posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com