Double-stage roof and floor surrounding rock damage range observation system

An observation system, roof and floor technology, applied in the direction of measurement, borehole/well components, mining equipment, etc., can solve the problems that numerical simulation cannot reflect the field situation well, the applicability of empirical formula is poor, and the blindness of empirical formula is large. Achieve the effect of reducing the number of system structures, simple structure, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

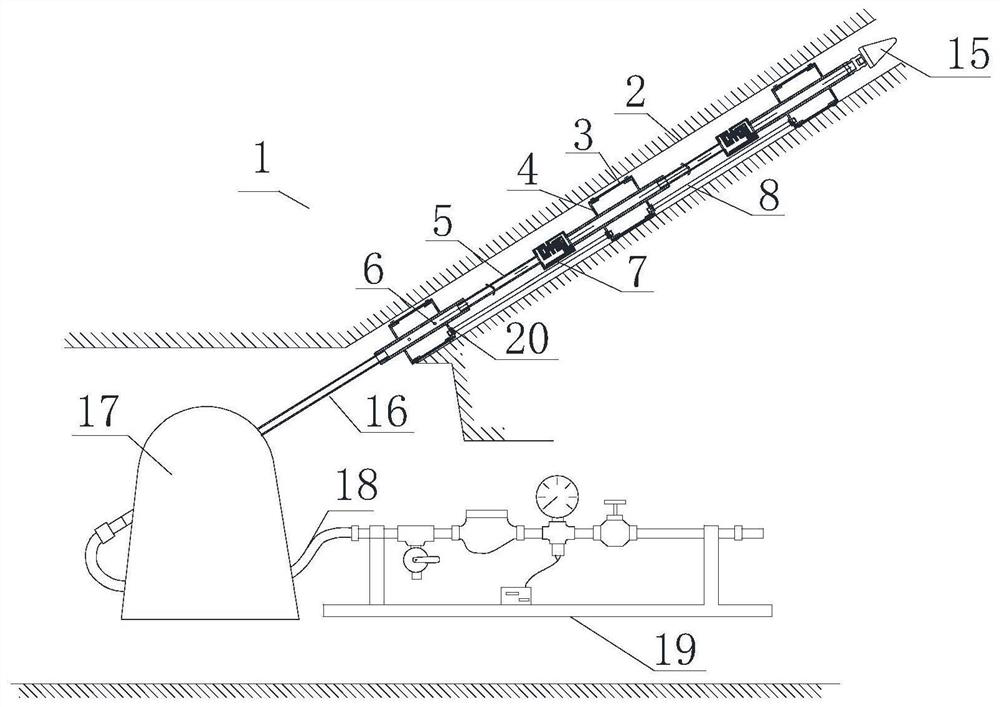

[0028] The present invention proposes a two-stage roof and floor surrounding rock damage range observation system. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

[0029] The two-stage roof and floor surrounding rock damage range observation system of the present invention combines Figure 1 to Figure 4 As shown, including plugging system, leak detection system, guiding system and propulsion supply system.

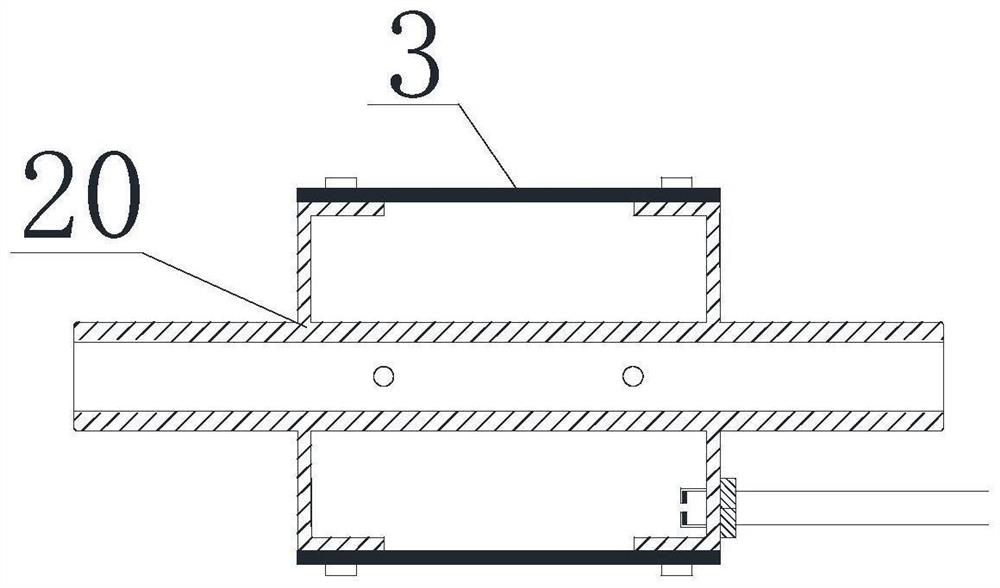

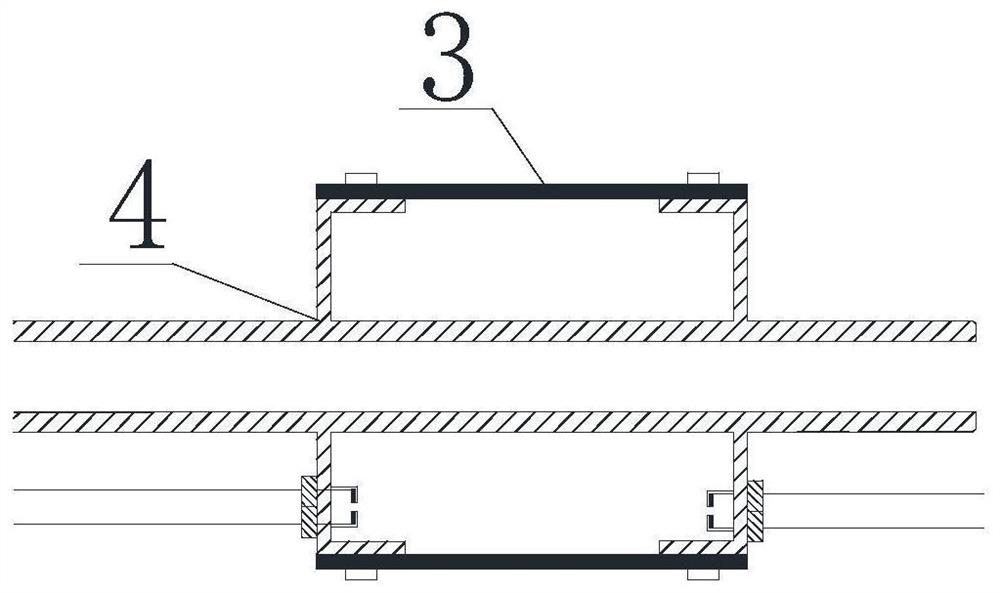

[0030] The plugging system includes a type I plugging support tube 20, a type II plugging support tube 4, a plugging capsule 3 and a capsule connecting tube 8, and two water leakage holes 6 are opened on the type I plugging support tube 20, and the inside thereof is There are two hollow pipes, type II plugging support pipe 4, which are respectively located in the middle and front of the leak detection system, on which the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com