Turbine blade disc structure service life reliability design method

A technology of turbine blisk and design method, applied in calculation, special data processing applications, instruments, etc., can solve the problems of quantifying structural failure, difficult to accurately give the actual life of the structure, etc., and achieve the effect of optimizing the turbine blisk structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

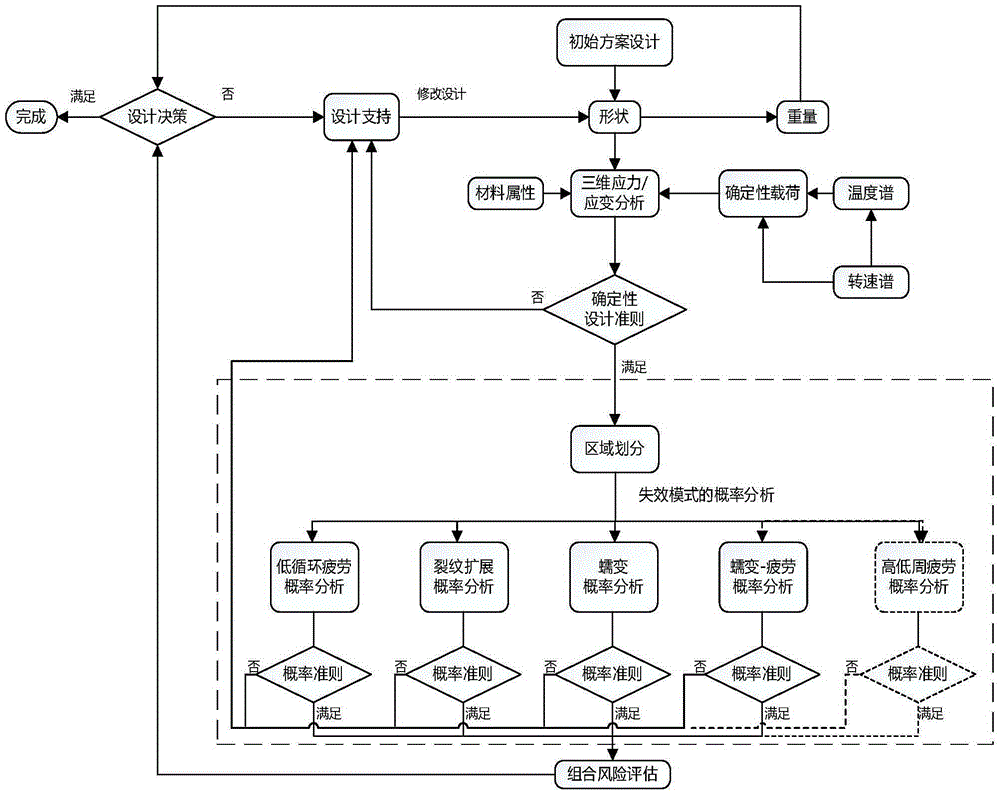

[0018] The technical solution of the design method for the life reliability of the turbine blisk structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Considering the dispersion of factors such as load, material and geometry, combined with the life reliability criterion of the turbine blisk structure, the design method for the life reliability of the turbine blisk structure proposed by the present invention, the process is shown in figure 1 .

[0020] (1) Design of the initial turbine blisk structure scheme: design and determine the initial scheme of the turbine blisk structure according to the traditional strength analysis method, and at the same time determine the geometry of the turbine blisk structure, and calculate the weight of the initial scheme, which will be used for subsequent design decisions Provide data basis;

[0021] (2) Deterministic detailed design: For the material selected for the turbine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com