An insulator and a method for improving the electric strength along the surface of the insulator

An insulator and surface area technology, which is used in the field of insulators and improving the electrical strength along the surface of insulators, can solve problems such as outstanding insulation problems, and achieve the effects of improved electrical resistance, low manufacturing technical difficulty, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

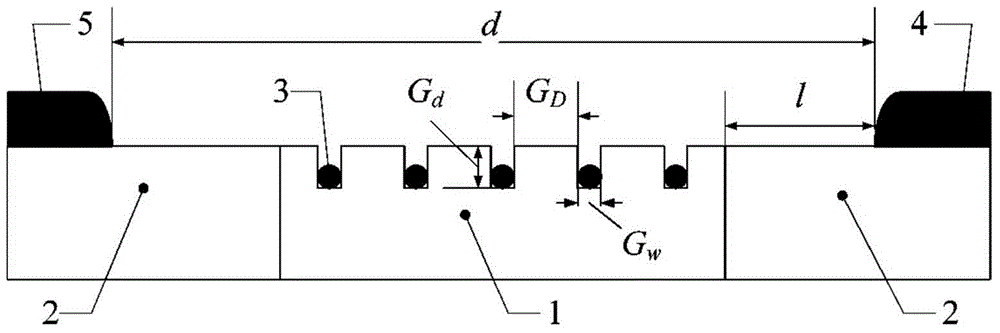

Method used

Image

Examples

Embodiment 1

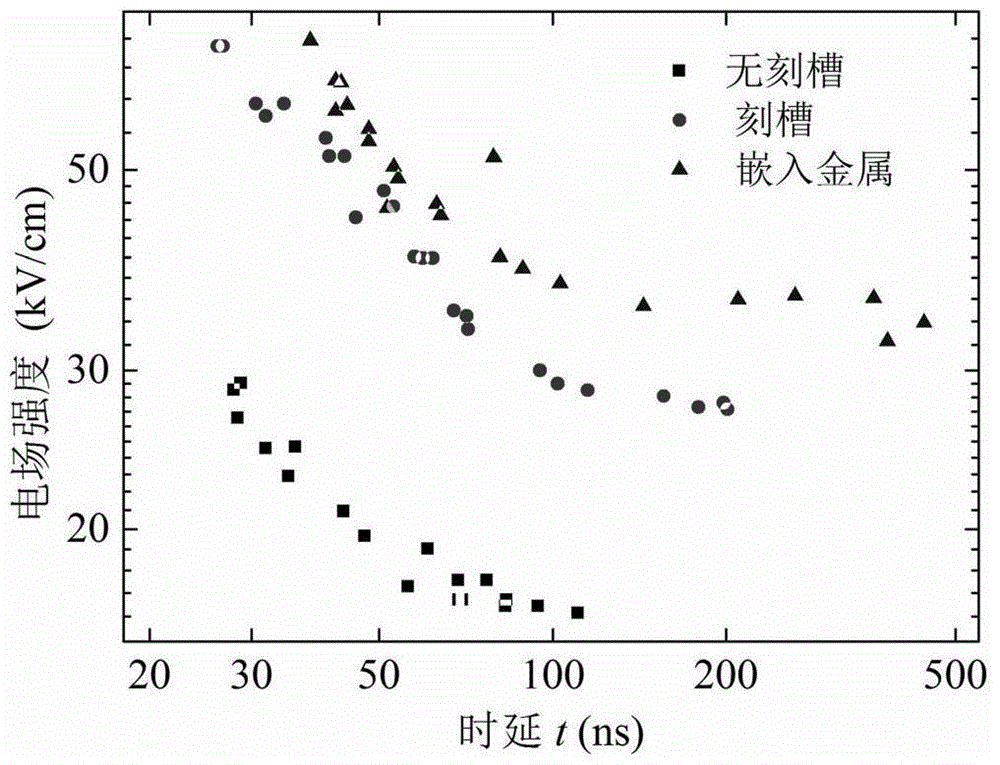

[0036] The groove area of the insulator is close to the cathode, the distance between the groove area and the cathode immediately l =0, the time delay characteristics of the surface flashover of the grooved insulator embedded in the electrode are as image 3 Shown. It can be seen from the figure that the flashover time delay after grooves on the surface of the insulator is greatly increased compared with that without grooves; when the electrodes are embedded in the grooves, the flashover time delay further increases. Table 1 shows the electric field intensity corresponding to different flashover time delays when the surface of the insulator has no groove, the groove near the cathode area, and the electrode is embedded in the groove. When the flashover time delay is 50ns, the flashover field strength of the groove on the surface is 43.4kV / cm, and the flashover field strength of the electrode embedded in the groove is 52.2kV / cm, and the electrode embedded in the groove is compar...

Embodiment 2

[0040] The groove position of the insulator is located in the middle area of the electrode, the distance between the groove area and the cathode l =5mm, Table 2 shows the electric field intensity corresponding to different flashover delays in the three cases of no grooves on the surface of the insulator, grooves near the cathode area, and electrodes embedded in the grooves. When the flashover time delay is 50ns, the flashover field strength of the groove on the surface is 26.7kV / cm, while the flashover field strength of the electrode embedded in the groove is 41.0kV / cm, and the electrode embedded in the groove is compared with that of the groove. The flashover field strength is increased by 53.5%; when the flashover time delay is 100ns, the flashover field strength of the groove on the surface is 22.3kV / cm, while the flashover field strength of the electrode embedded in the groove is 29.8kV / cm, while The flashover field strength of the embedded electrode is increased by 33.6% ...

Embodiment 3

[0044] The groove position of the insulator is close to the anode, the distance between the groove area and the cathode immediately l =10mm, Table 3 shows the electric field intensity corresponding to different flashover time delays in the three cases of no grooves on the surface of the insulator, grooves near the cathode area, and electrodes embedded in the grooves. When the flashover time delay is 50ns, the flashover field strength of the groove on the surface is 41.9kV / cm, and the flashover field strength of the electrode embedded in the groove is 57.4kV / cm, and the electrode embedded in the groove is compared with that of the groove. The flashover field strength is increased by 37.0%; when the flashover time delay is 100ns, the flashover field strength of the groove on the surface is 30.1kV / cm, while the flashover field strength of the electrode embedded in the groove is 39.0kV / cm, and the groove The flashover field strength of the embedded electrode is increased by 29.6% co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com