Preparation method of nano-modified film material capable of improving surface electrical resistance of polymer insulating material

A nano-modification, membrane material technology, applied in the coating and other directions, can solve the problems of poor controllability, unstable treatment effect, limited duration of fluorination effect, etc., to achieve high controllability, excellent adhesion, The effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

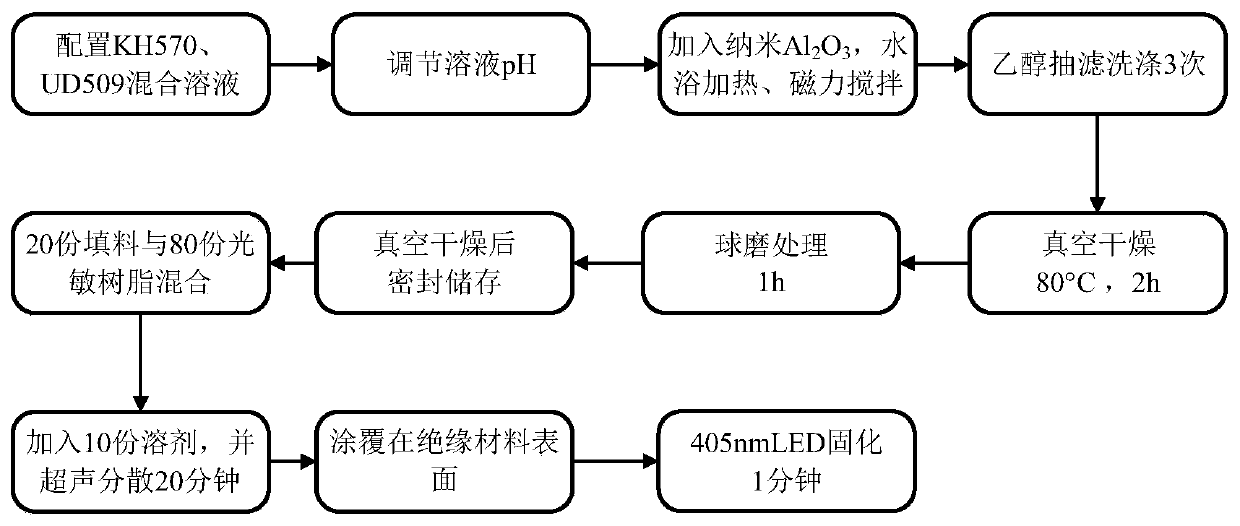

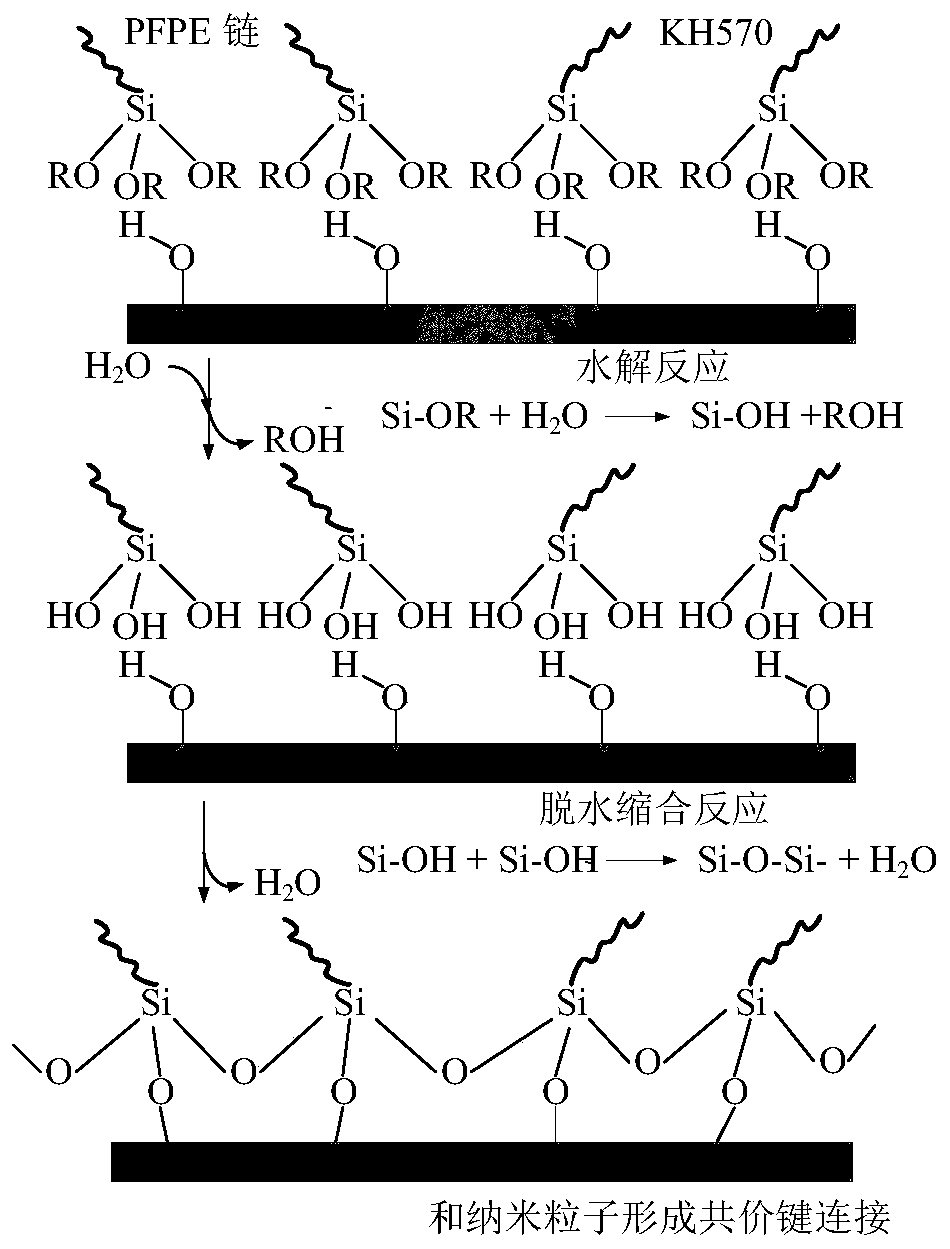

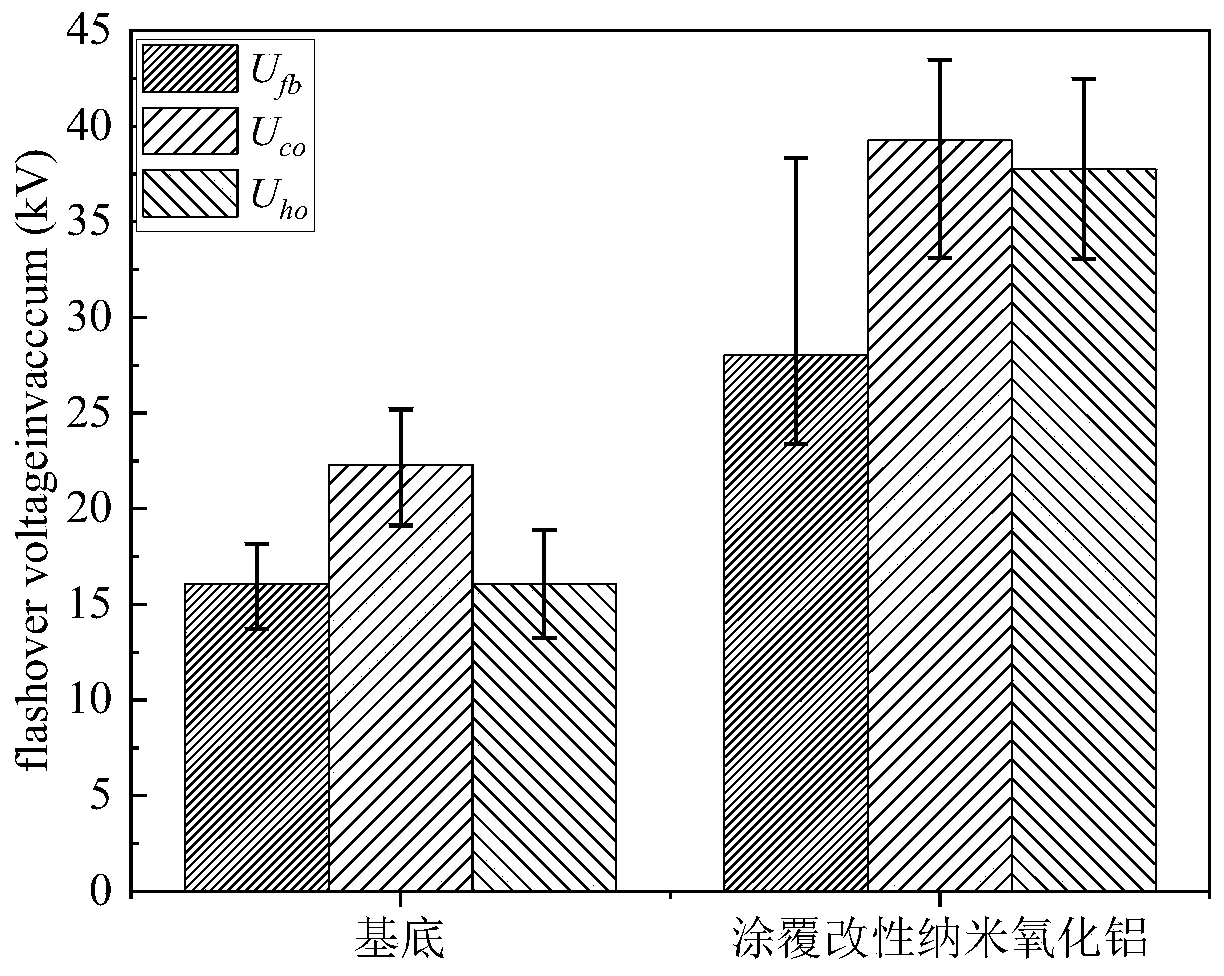

[0039] see figure 1 , a preparation method of nano-modified film materials for improving polymer insulation surface resistance, firstly through silane coupling, silane-modified perfluoropolyether and KH570 (γ -(methacryloyloxy)propyltrimethoxysilane) grafted onto the surface of the nanoparticle material to prepare a modified nanopowder; then add the modified nanopowder to the photocurable resin according to a certain proportion, After ultrasonic treatment, stirring and solution dispersion, etc., it is evenly coated on the surface of the insulating material by spraying or roller coating, and finally, the rapid curing of the resin is completed by irradiation with an LED ultraviolet light source with a wavelength of 365nm or 405nm; the specific steps are as follows:

[0040] S1. Through silane coupling, graft photocurable KH570 and silane-modified perfluoropolyether onto the surface of nanoparticles such as alumina, silica or zinc oxide, and achieve double Coupling to obtain mod...

Embodiment 1

[0061] Preparation of modified nanoparticles:

[0062] (1) Prepare the solution

[0063] To treat 100g of nano-alumina, first add KH570 with a concentration of 2wt%, then add modified perfluoropolyether with a concentration of 2wt%, and finally add it to 100ml of 95% ethanol to prepare a mixed solution;

[0064] (2) Adjust the pH of the solution

[0065] According to the pH value of the solution corresponding to each group of tests, use glacial acetic acid and 25% ammonia water to adjust the pH of the solution to 5;

[0066] (3) Coupling

[0067] Put the prepared solution into a round bottom flask, heat it to the corresponding temperature of the test plan by using a water bath, add 100g of nano-alumina, and react for 1h under the dispersion mode of magnetic stirring (100r / min). Condensation reflux;

[0068] (4) cleaning

[0069] Wash the nanoparticles multiple times with a suction filter to remove residues that have not undergone a coupling reaction with the surface of th...

Embodiment 2

[0078] Preparation of modified nanoparticles:

[0079] (1) Prepare the solution:

[0080] To treat 100g of nano-alumina, first add KH570 with a concentration of 3wt%, then add modified perfluoropolyether with a concentration of 3wt%, and finally add it to 100ml of 95% ethanol to prepare a mixed solution;

[0081] (2) Adjust the pH of the solution

[0082] According to the pH value of the solution corresponding to each group of tests, use glacial acetic acid and 25% ammonia water to adjust the pH of the solution to 5;

[0083] (3) Coupling

[0084] Put the prepared solution into the round bottom flask, heat it to the corresponding temperature of the test plan by using a water bath, add 100g of nano-alumina, and react for 1.2h under the dispersion mode of magnetic stirring (120r / min). carry out condensation reflux;

[0085] (4) cleaning

[0086] Wash the nanoparticles multiple times with a suction filter to remove residues that have not undergone a coupling reaction with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com