Complete equipment for cleaning glass

A complete set of device and glass technology, applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problems of low cleaning efficiency and poor cleaning quality of double-sided glass wiping, achieve better cleaning effect, save water resources, improve cleaning quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

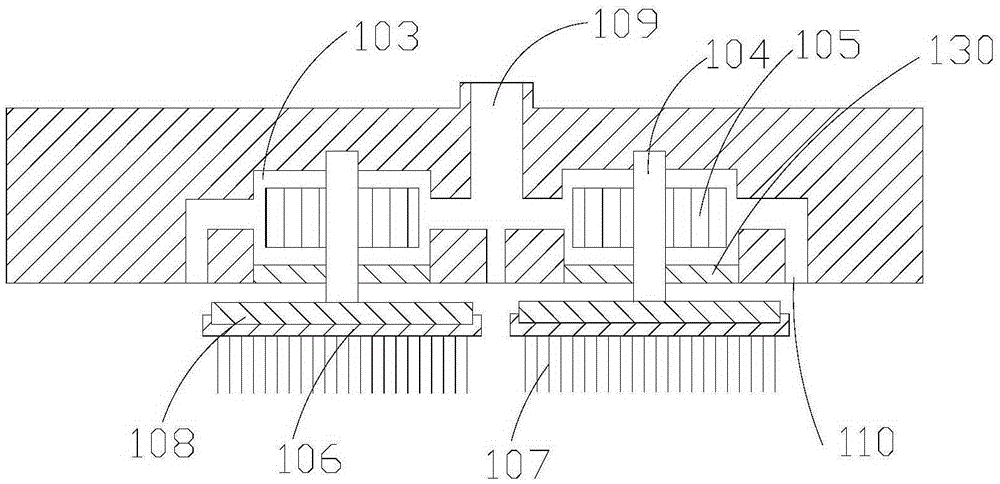

[0046] Example 1, reference figure 1

[0047] A complete device for cleaning glass includes an inner wiper 101 and an outer wiper 102. Both the inner wiper 101 and the outer wiper 102 are provided with a first circular groove 103 and a first central shaft 104. The bottom of the inner wiper 101 and the bottom of the outer wiper 102 are both provided with a cleaning body, the first circular groove 103 is provided with a first impeller 105, and the first impeller 105 and the cleaning body pass through the first central axis 104 is connected, the cleaning body is provided with a strong magnet 108, the inner wiper 101 and the outer wiper 102 are both provided with a water inlet 109, the bottom of the inner wiper 101 and the bottom of the outer wiper 102 are both provided There is a water outlet 110, the water inlet 109 and the water outlet 110 in the inner wiper 101 are both in communication with the first circular groove 103 in the inner wiper 101, and the water inlet 109 and the out...

Example Embodiment

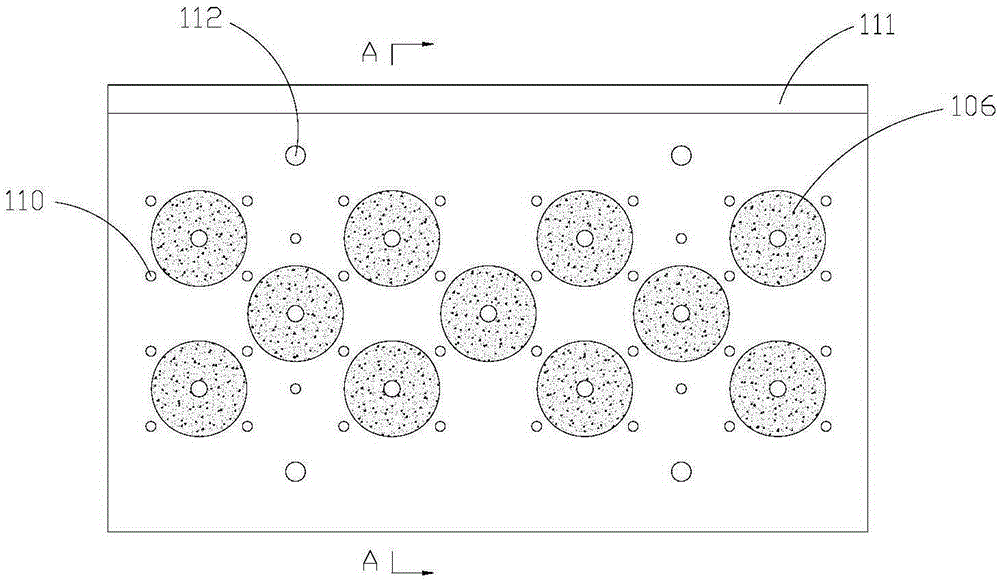

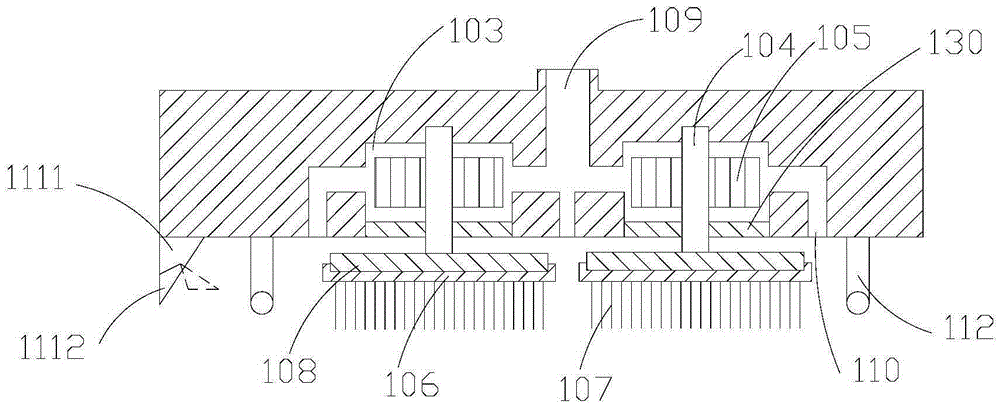

[0052] Example 2, reference Figure 2 to Figure 4

[0053] The implementation principles and technical effects of the device provided in the embodiment of the present invention are the same as those of the foregoing method embodiment. For a brief description, for the parts not mentioned in the device embodiment, please refer to the corresponding content in the foregoing method embodiment.

[0054] In this embodiment, such as figure 2 , image 3 As shown, the inner wiper 101 is provided with three rows of brush discs 106. An end cover 130 is provided at the bottom of the first circular groove 103, and the end cover 130 seals the bottom of the first circular groove 103. The lower surface of the inner wiper 101 is provided with a turning scraper 111. The turning scraper 111 includes a fixed portion 1111 and a rotating portion 1112. After the upper surface of the rotating portion 1112 contacts the lower surface of the fixed portion 1111, the rotating portion 1112 can be opposed to the...

Example Embodiment

[0064] Example 3, reference Figure 5 , Image 6

[0065] The difference between this embodiment and the second embodiment is that the top of the outer wiper 102 is provided with a second circular groove 123, and the water inlet 109 in the outer wiper 102 communicates with the second circular groove 123 , The second circular groove 123 communicates with the first circular groove 103 in the outer wiper 102, and the water outlet 110 in the outer wiper 102 is connected to the first circular groove in the outer wiper 102 103 is connected, that is, after the cleaning medium enters the water inlet 109, it first enters the second circular groove 123, and then enters the first circular groove, so as to ensure that the outer wiper 102 has sufficient power during the automatic operation. A second central shaft 124 is provided on the outer wiper 102, a second impeller 125 and a rotating plate 126 are sleeved on the second central shaft 124, and the second impeller 125 is arranged in the sec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap