Railway flatcar provided with end doors and foldable moving cover

A technology of movable shed and flat car, which is applied in the direction of railway car body, railway car body parts, transportation and packaging, etc. It can solve the problems of limiting the loading space of transported goods, cannot be completely folded, and the shrinkage distance is limited, so as to facilitate vertical lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

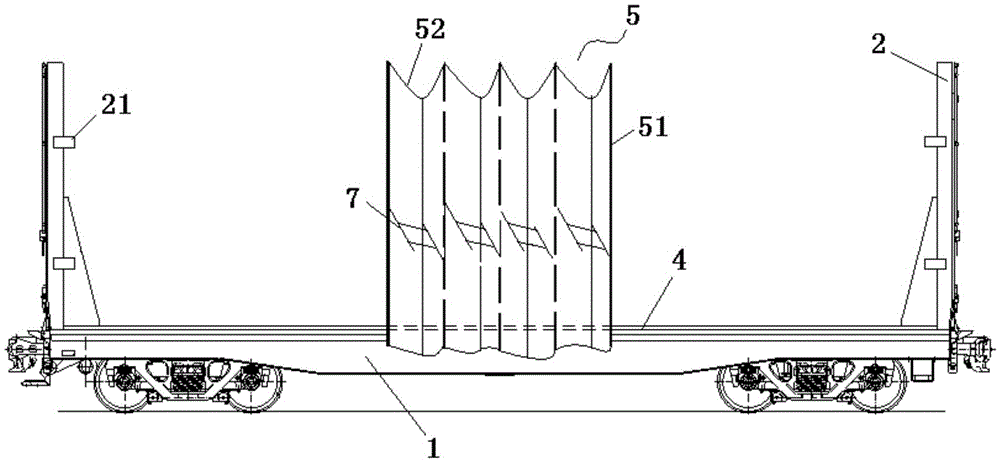

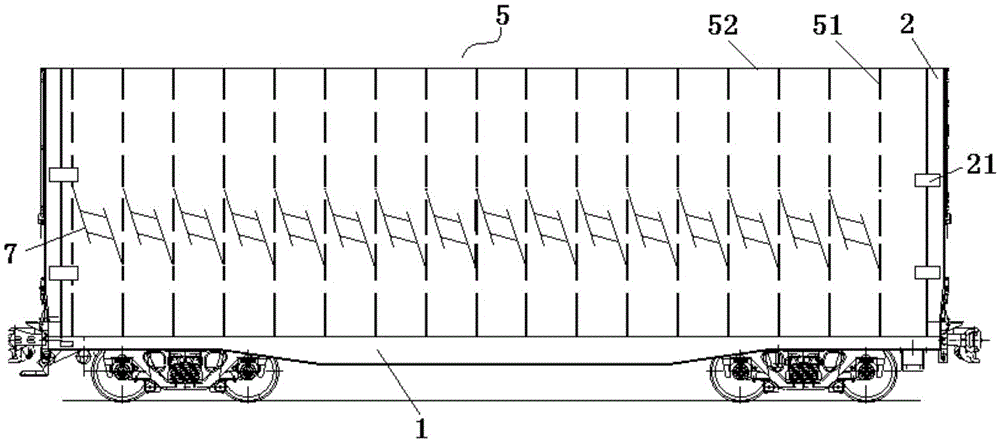

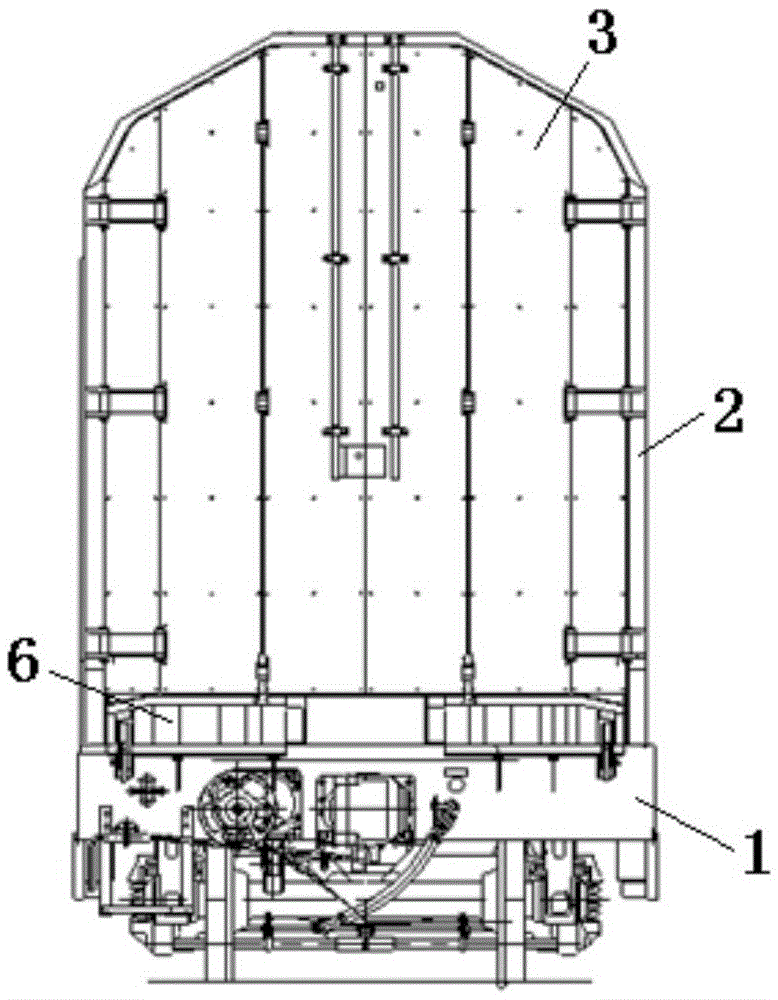

[0017] Such as Figure 1~3 As shown, the present invention includes two end walls 2 arranged at both ends of the bottom frame of the flat car, and movable end doors 3 are arranged on the end walls 2 . A slideway 4 is provided on the two side beams of the underframe composition 1 respectively. A movable shed 5 is slidably set on the two slideways 4 . The activity shed 5 includes a plurality of frameworks 51 which are arranged side by side and slidably connected in the slideway 4 , and each framework 51 supports a foldable flexible sealing cover 52 together.

[0018] In the above embodiment, a foldable connecting piece 7 is arranged between every two adjacent frames 51 to assist the folding and stretching of the movable shed 5 .

[0019] In the above embodiments, the foldable connecting member 7 adopts a link mechanism.

[0020] In the above embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com