Liquid processing apparatus, liquid processing method, and storage medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

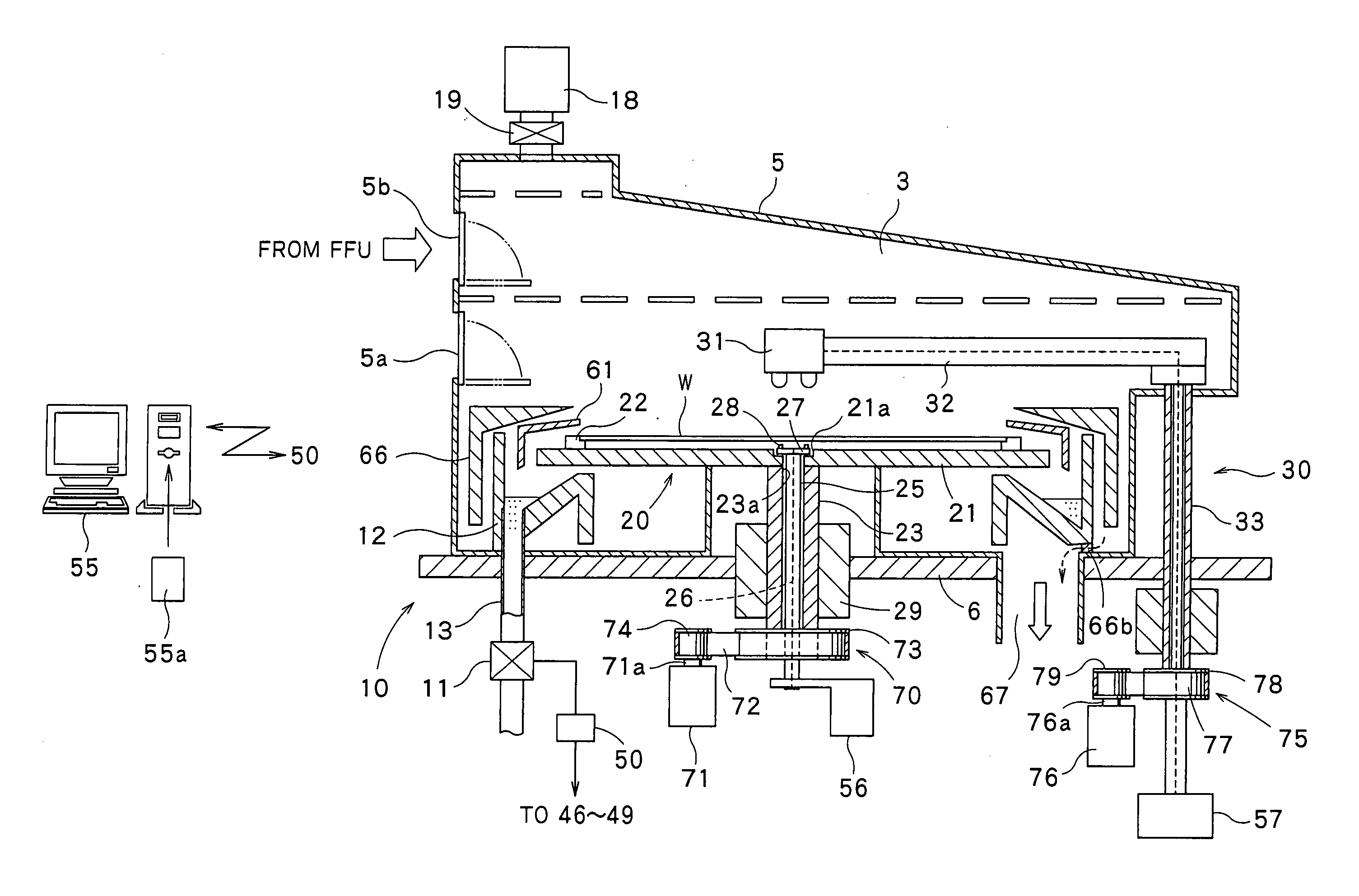

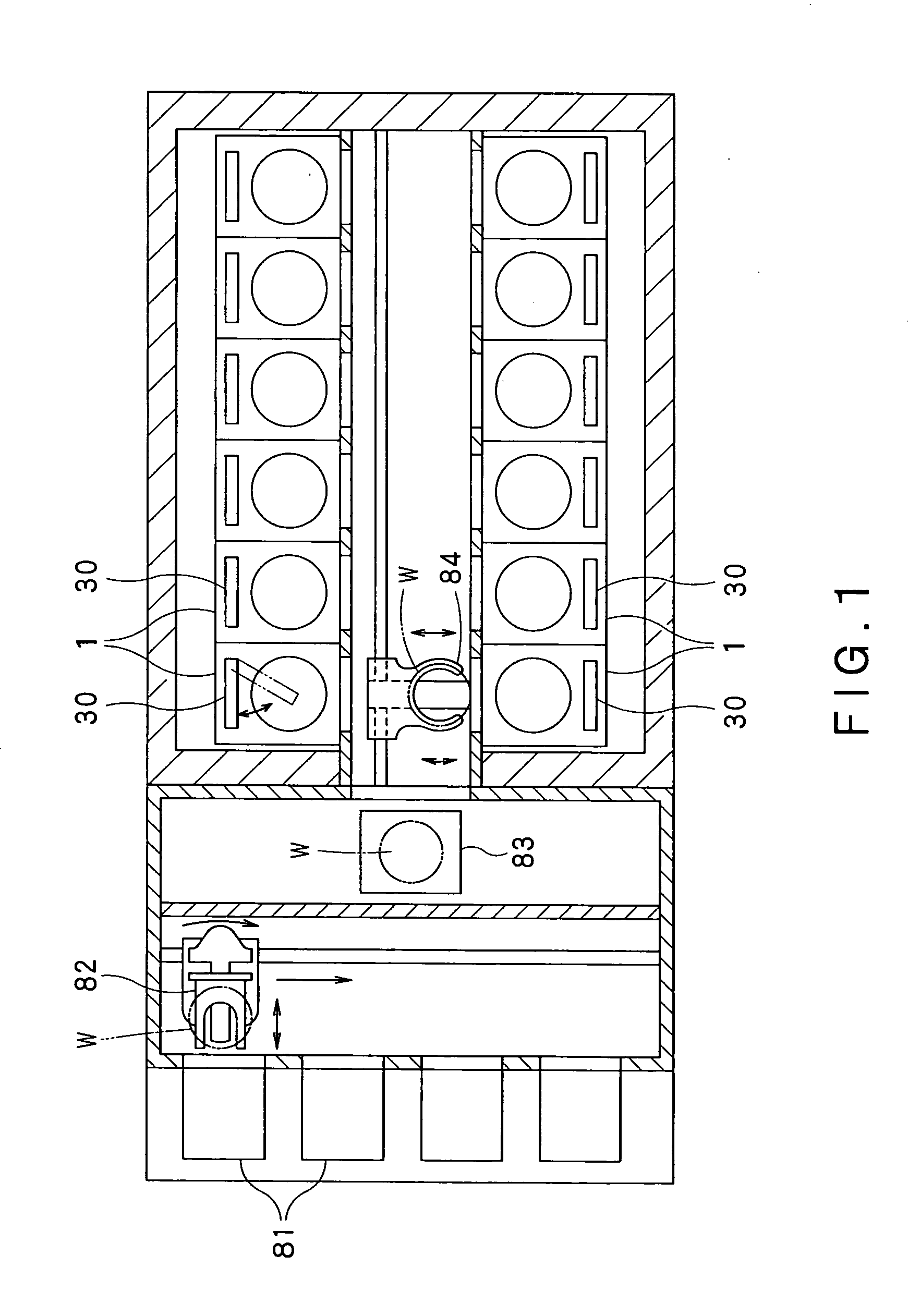

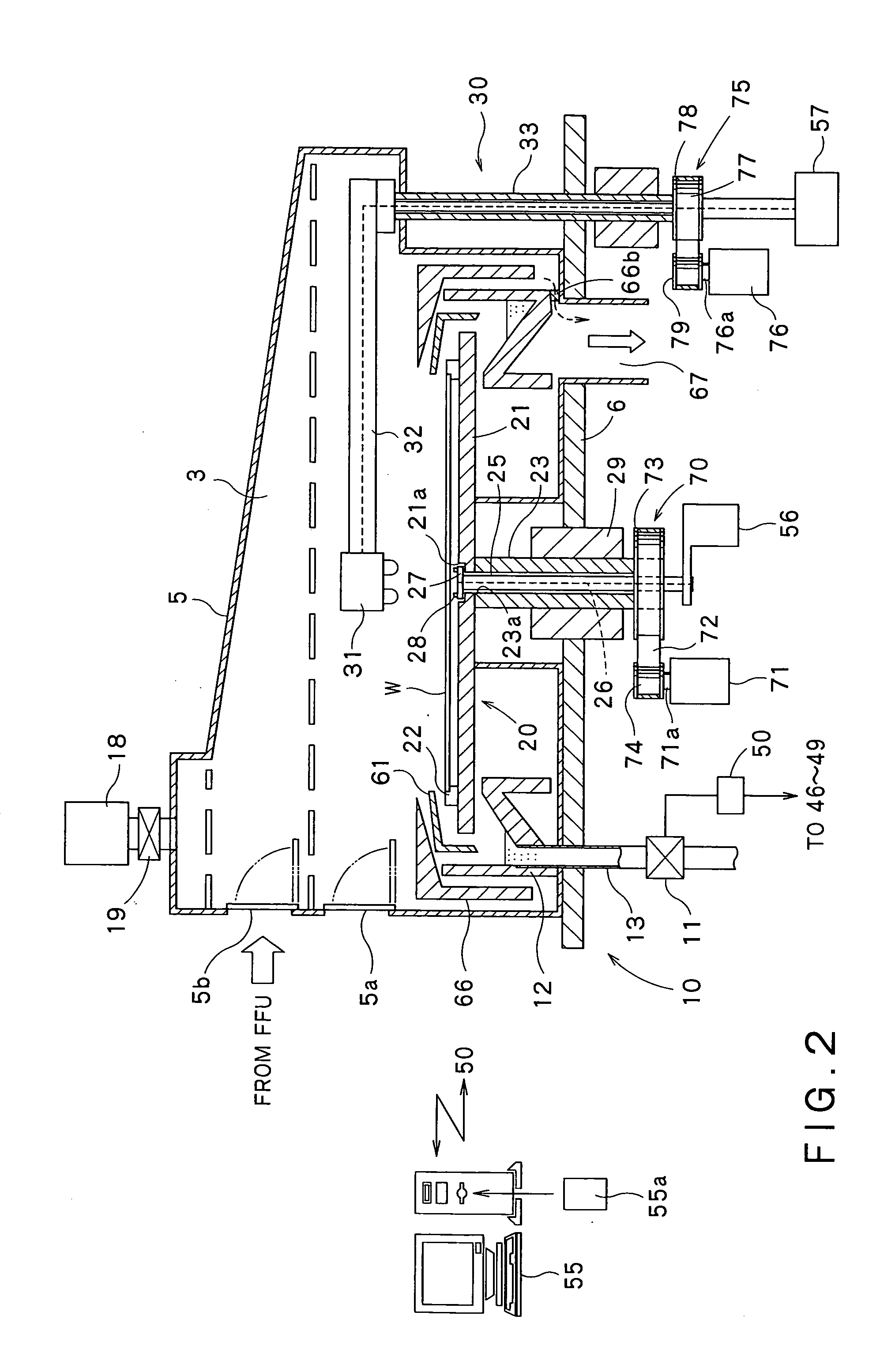

[0041]A first embodiment of a liquid processing apparatus, a liquid processing method, and a storage medium, of the present invention is described herebelow with reference to the drawings. FIGS. 1 to 5 show the first embodiment of the present invention.

[0042]As shown in FIG. 1, a liquid processing system includes: a stage 81 in which a carrier loaded from outside is placed, the carrier accommodating a semiconductor wafer W (hereinafter simply referred to also as “wafer W”) that is a substrate to be processed; a transfer arm 82 that takes out the wafer W accommodated in the carrier; a shelf unit 83 on which the wafer W taken out by the transfer arm 82 is placed; and a main arm 84 that receives the wafer W placed on the shelf unit 83 and conveys the wafer W into a liquid processing apparatus 11. Incorporated in the liquid processing system are the plurality of liquid processing apparatuses (twelve in this embodiment). FIG. 1 is an upper plan view of the liquid processing system includ...

second embodiment

[0093]Next, a second embodiment of the present invention is described with reference to FIG. 6. In the second embodiment shown in FIG. 6, a cleaning mechanism (removing mechanism) 10 that removes an alkaline component adhering to a draining cup 12 is constituted, in place of the cleaning-liquid supplying mechanism, the draining pipe 13, and the blocking valve 11, by a cleaning-liquid jetting mechanism 15 that jets deionized water (cleaning liquid) D to the draining cup 12 so as to remove the alkaline component adhering to the draining cup 12. Further, an annular exhaust cup 66 located on an outer peripheral side of the draining cup 12 is capable of being moved in an up and down direction (see, arrow A2 in FIG. 6). Other structures of the second embodiment are substantially the same as those of the first embodiment shown in FIGS. 1 to 5.

[0094]In the second embodiment shown in FIG. 6, the same parts as those of the first embodiment shown in FIGS. 1 to 5 have the same reference numbers...

third embodiment

[0105]Next, a third embodiment of the present invention is described with reference to FIG. 7. In the third embodiment shown in FIG. 7, in place of the provision of the cleaning mechanism 10 that removes the alkaline component in the casing 5, a dry-gas supplying part 18 serves as a pressurizing mechanism (invasion preventing mechanism) that prevents invasion of an alkaline component into a casing 5. Specifically, an air pressure of a dry gas flowing into the casing 5 from the dry-gas supplying part 18 is increased to thereby prevent the invasion of an alkaline component into the casing 5. Other structures of the third embodiment are substantially the same as those of the first embodiment shown in FIGS. 1 to 5.

[0106]In the third embodiment shown in FIG. 7, the same parts as those of the first embodiment shown in FIGS. 1 to 5 have the same reference numbers, and a detailed description thereof is omitted.

[0107]As shown in FIG. 7, connected to the casing 5 is a pressurizing mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com