Novel logistic trolley

A logistics and trolley technology, applied in trolleys, multi-axle trolleys, motor vehicles, etc., can solve the problems of large losses, impact on goods, and limit the performance and safety performance of logistics trolleys, so as to improve the performance and safety performance, The effect of good shock absorption protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

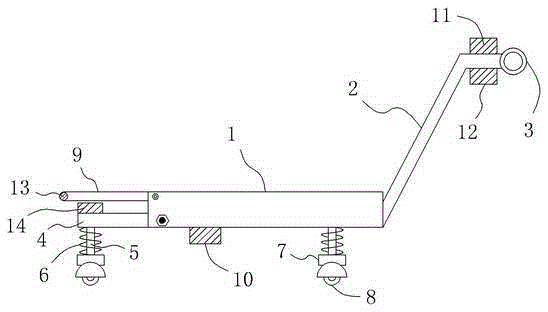

[0014] like figure 1 As shown, a new logistics trolley includes a base 1 and a push rod 2 located on the right side of the base 1. A handle 3 is also provided on the top of the push rod 2. The bottom bar hole (not shown in the figure) extending to the right in the length direction of the base 1 is embedded with a bottom bar 4 that is slidably connected to the bottom bar hole. The left end of the bottom of the rod 4 is also respectively connected with a telescopic rod 5 extending vertically downward, and a helical damping spring 6 is sleeved on the outside of the telescopic rod 5, and the bottom end of the telescopic rod 5 is also connected with a mounting base 7, There are also walking wheels 8 on the mounting base 7; at least two extension rod holes (not shown in the figure) parallel to each other and extending to the right along the length direction of the base 1 are opened on the upper part of the left side of the base 1, An extension rod 9 that is slidably connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com