Good pocket for fertilizer bunching stacking

A group, chemical fertilizer technology, applied in the field of cargo pockets, can solve the problems of rupture and failure of net pockets, stress deformation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

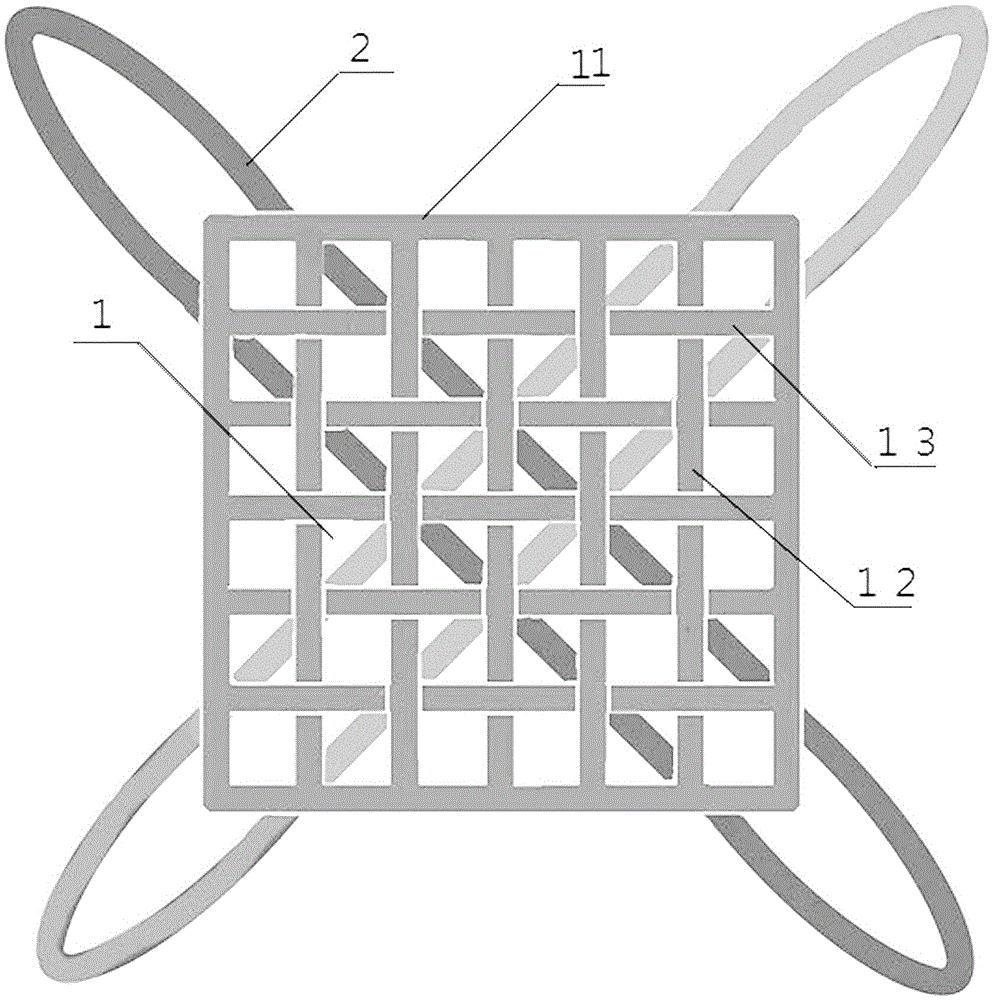

[0012] As shown in the figure, a cargo bag for stacking chemical fertilizers in groups includes a hanging net 1 and two lifting lugs 2. The hanging net 1 includes an outer ring 11, a longitudinal belt 12 and a horizontal belt 13. The outer ring is A square or circular airtight circle surrounded by belts or ropes, preferably a square outer ring 11, the plurality of longitudinal belts 12 and a plurality of horizontal belts 13 are intersected to form a network, and each of the vertical belts 12 and The ends of the horizontal band 13 are fixedly sewn to the outer ring 11 .

[0013] The lifting lugs 2 are connected end to end by the slings to form a long oval shape. The two lifting lugs 2 are intersected in a well shape along the diagonal direction of the hanging net 1 and are sutured and placed on the bottom of the hanging net 1. Both ends of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com