High-precision head lamp assembly detecting tool

A headlight, high-precision technology, applied in instruments, measuring devices, mechanical devices, etc., can solve the problems of affecting the loading effect, cumbersome detection steps, low detection accuracy, etc., to achieve convenient and fast detection, and improve aesthetics. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

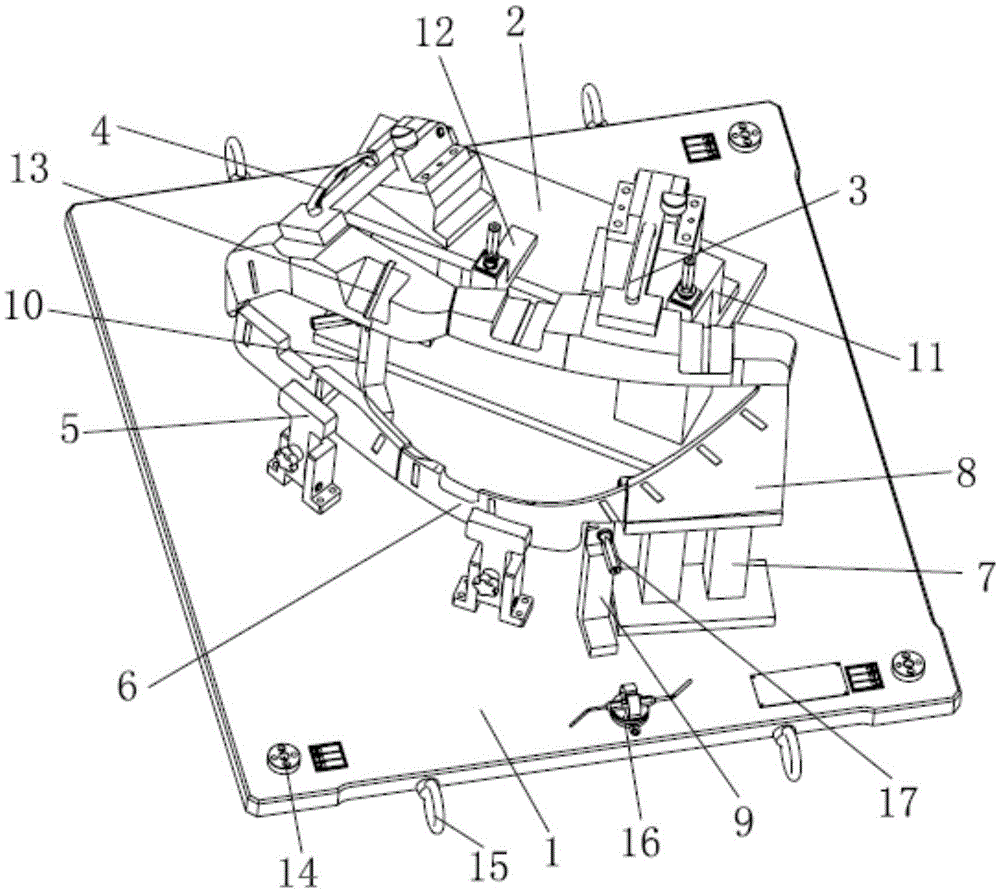

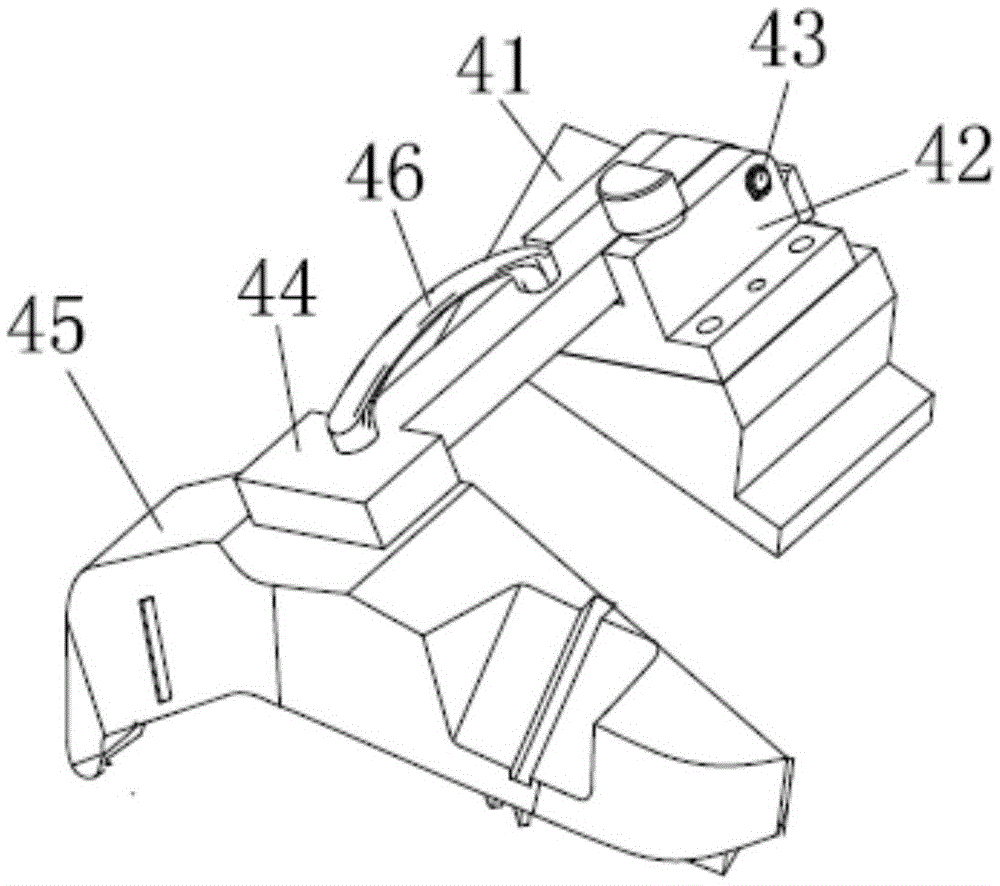

[0020] The present invention's high-precision headlight assembly inspection tool, such as figure 1 As shown, base 1 is included, and base 1 is provided with a frame based on the sheet metal data around the headlight assembly of the real vehicle to place the headlight assembly, and a positioning block that simulates the assembly and installation of the real vehicle to fix the headlight assembly . The frame is composed of turning mechanism I3, turning mechanism II4 on the upper side, turning mechanism III5, turning mechanism IV6 and fixed profile 8 on the lower side, turning mechanism I3, turning mechanism II4, turning mechanism III5, turning mechanism IV and 6 are all rotatable opening and closing structures. The multi-directional controllable opening and closing detection device is convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com