Pixel array and repairing method for pixel unit

A pixel array and pixel unit technology, applied in electrical components, optics, instruments, etc., can solve the problems of pixel electrodes not being connected to the common potential, failure of dark spots, complex display panels, etc., and achieve good display quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are described in detail

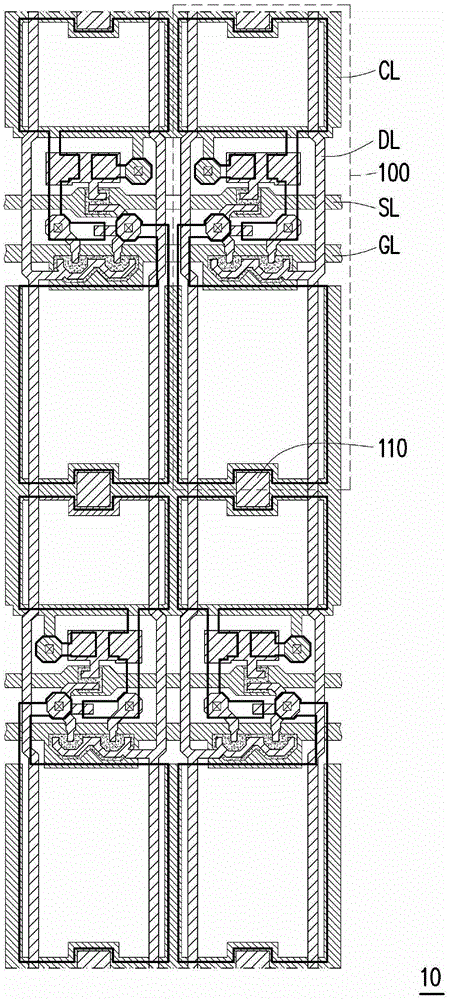

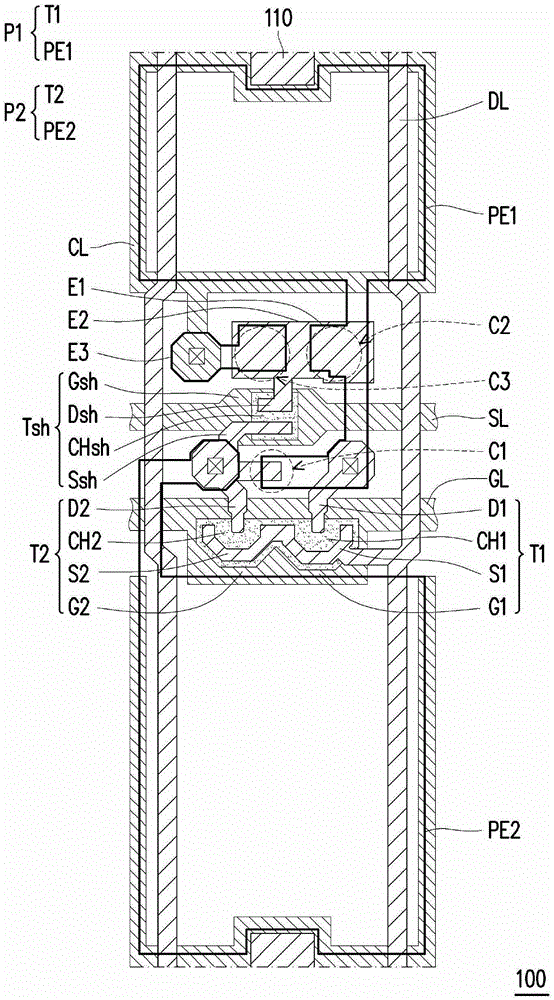

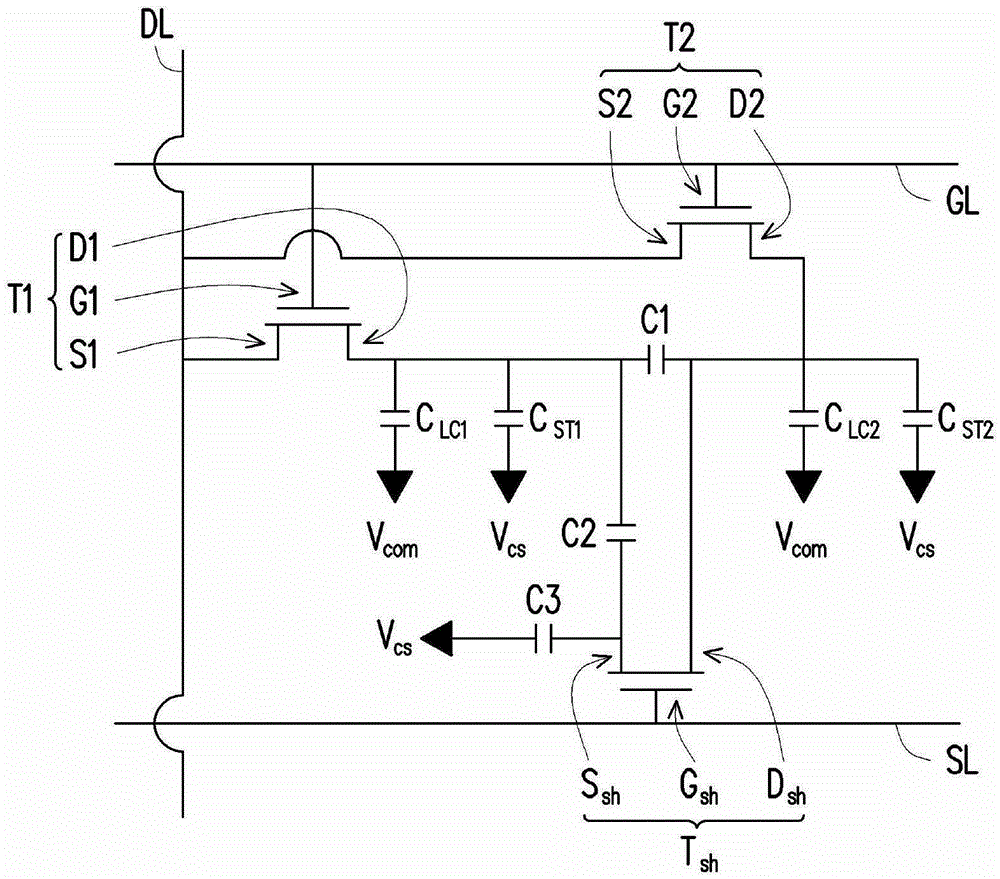

[0068] Figure 1A is a schematic diagram of a pixel array according to an embodiment of the present invention, Figure 1B for Figure 1A A partial enlarged schematic diagram of a pixel unit, Figure 1C for Figure 1B Schematic diagram of the equivalent circuit of the pixel unit. For the convenience of illustration, in Figure 1AIn the figure, it is taken that the pixel array includes 2×2 pixel units as an example, but the present invention is not limited thereto.

[0069] Please also refer to Figure 1A to Figure 1C , the pixel array 10 includes a plurality of pixel units 100 . Each pixel unit 100 includes a first sub-pixel P1, a second sub-pixel P2, a scan line GL and a data line DL. The first sub-pixel P1 includes a first active element T1 and a first pixel electrode PE1. The first active device T1 includes, for example, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap