Wafer transmission device and vacuum adsorption manipulator thereof

A vacuum adsorption and manipulator technology, which is applied to conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of unqualified wafer 1, reduce the qualified rate of wafer 1, etc., and achieve the effect of improving the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

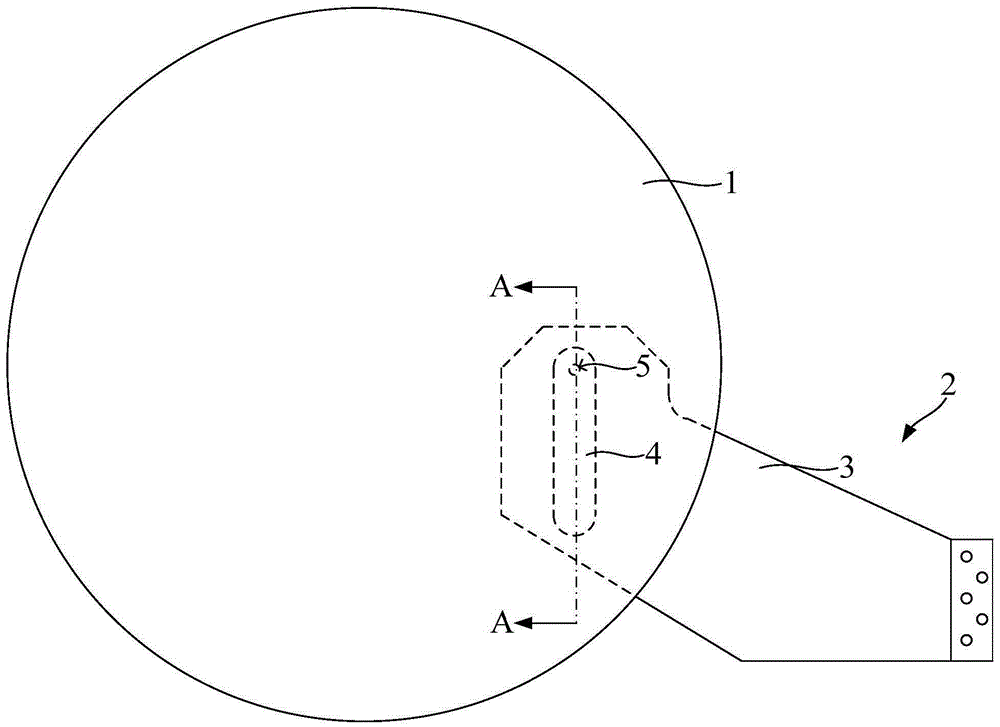

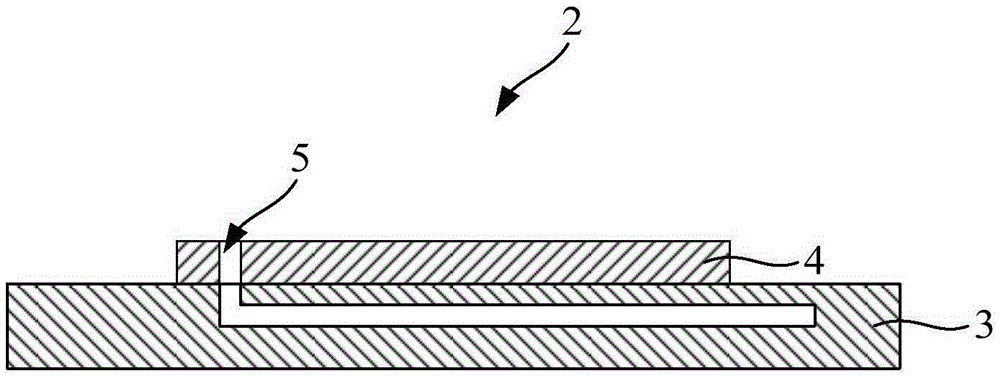

[0039] combine Figure 4 to Figure 5 As shown, this embodiment provides a vacuum suction manipulator 10 for transferring wafers, which includes an arm 11 , and a suction insulating boss 12 and a dummy insulating boss 13 fixed on the arm 11 . Wherein, the adsorption insulating boss 12 is ring-shaped, and the false insulating boss 13 is located in the adsorption insulating boss 12, and is integrally formed with the arm 11. On the direction V perpendicular to the arm 11, the adsorption insulating boss 12 is larger than the pseudo insulating boss 12 13 stand out.

[0040] The arm 11, the false insulation boss 13 and the adsorption insulation boss 12 are provided with a vacuum air channel 14, and according to the flow direction of the air in the vacuum air channel 14, the vacuum air channel 14 is successively formed by the first segment air channel 140 (in the figure). Shown by dotted lines), the second segment air channel 141, and the third segment air channel 142, wherein the fi...

no. 2 example

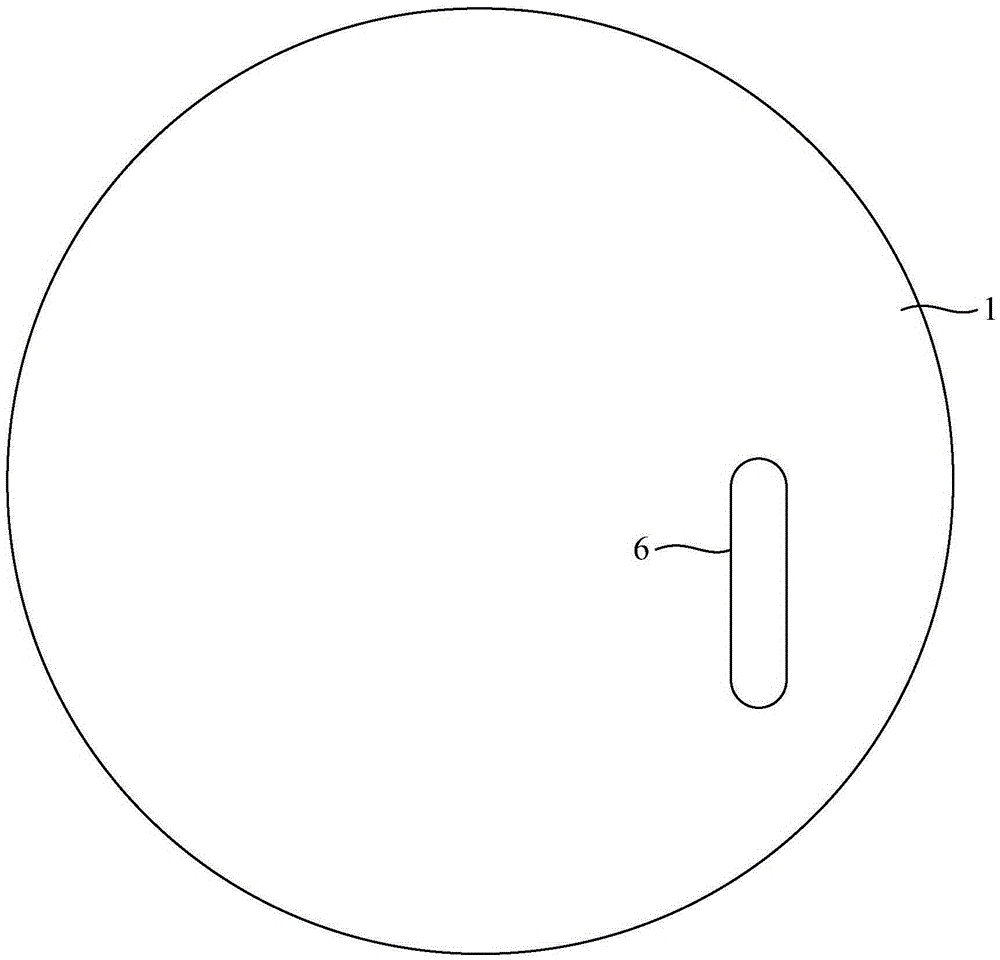

[0050] combine Figure 6 to Figure 7 As shown, the difference between the second embodiment and the first embodiment is that in the second embodiment, no pseudo-adsorption boss is set in the vacuum adsorption manipulator 10, and the adsorption insulation boss 12 is a solid column, and the vacuum air channel 14 is arranged on the arm 11 and the adsorption insulation boss 12.

[0051] It should be noted that, in the technical solution of the present invention, the adsorption insulating bosses, arms, and false insulating bosses can be set in any shape, and should not be limited to those shown in the accompanying drawings.

[0052] In addition, the present invention also provides a wafer transfer device, which includes the above-mentioned vacuum adsorption manipulator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com