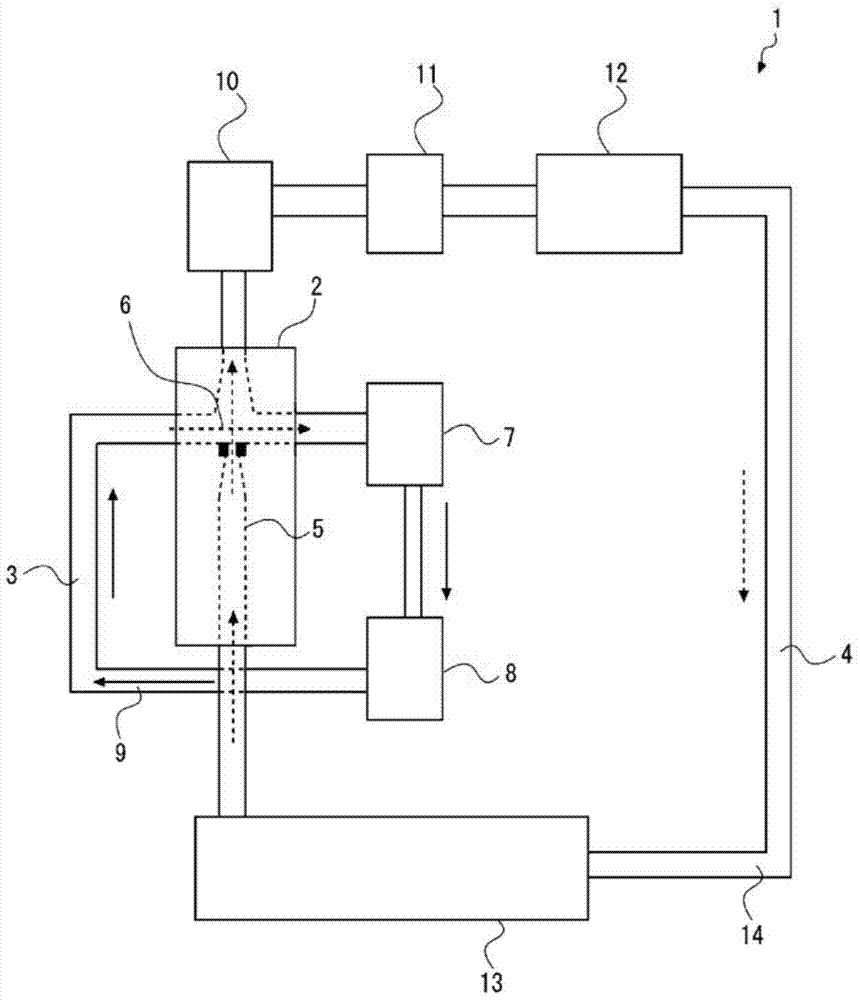

Apparatus for manufacturing nano-fine products and method for manufacturing nano-fine products

A micro-product technology, applied in the field of devices for manufacturing nano-micro products, can solve the problems of easy blocking and unstable quality, and achieve the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

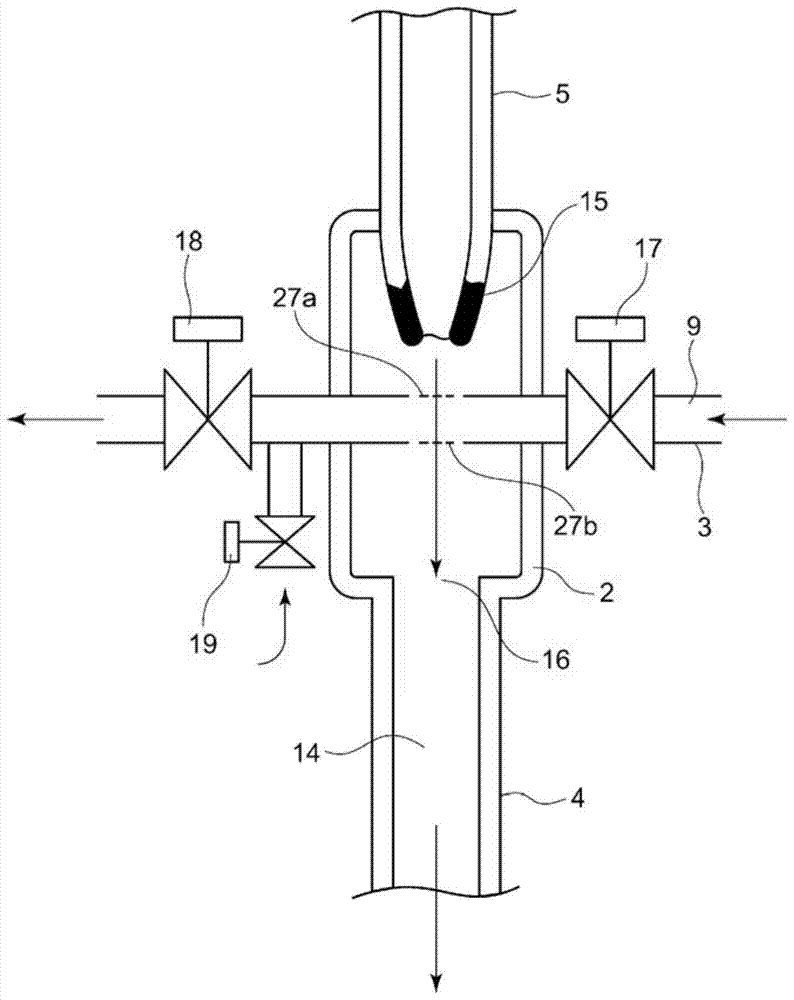

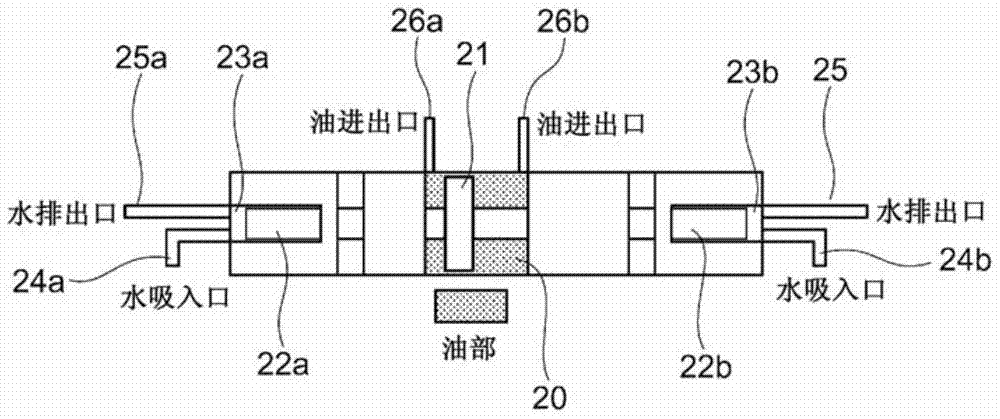

[0074] Embodiment 1. First, through-holes 27a, b are formed in the rubber tube 9 by the high pressure generated by the circulation of water or fine polysaccharide slurry. Secondly, the polysaccharide slurry flowing in the circulation path of the rubber tube 9 is treated only once with high-pressure water to make it nano-sized. The supplied fibrous polysaccharide was adjusted to a 3% slurry with hardwood bleached pulp (LBKP) and circulated. The pressure of the injected high-pressure water was set at 200 MPa. The concentration of the obtained nano fine slurry was 1.09%. 200 cc of the nano fine slurry that has been processed only once is filtered with a Buchner funnel. The time required for filtration is 80 seconds in the case of untreated pulp, but 25 minutes for nano-fine pulp. From then on, it can be confirmed that the pulp has been nano-sized as long as the dehydration time is required.

[0075] [Table 1]

[0076]

before processing

Example 1

conce...

Embodiment 2

[0080] Embodiment 2, same as Embodiment 1, spray high-pressure water from the hole injection port 15 of the hole injection part 5 of the second liquid medium supply path 4 to the hardwood bleached pulp (LBKP) pulp flowing in the polysaccharide slurry supply path 3 material, pass it through and recycle it. The jet high pressure water pressure is set to 200MPa. The concentration, freeness, transmittance (%), polymerization degree and sedimentation height of the recovered nano fine slurry are measured. The freeness was evaluated by the amount of water filtered and dropped from 200 cc of a 0.1% CeNF aqueous solution. The transmittance (%) was evaluated by the transmittance of a 0.1% CeNF aqueous solution, and was measured at wavelengths of 400 nm and 600 nm. In addition, the concentration, freeness, The transmittance (%) and the degree of polymerization were also measured as Comparative Example 1.

[0081] [Table 2]

[0082]

[0083]

[0084] ※1 The freeness is the amou...

Embodiment 3

[0088] Example 3: The nano fine slurry obtained in Example 2 is injected from the orifice injection port 15 of the orifice injection part 5 of the second liquid medium supply path 4 and circulated in the second liquid medium supply path 4 .

[0089] The injection pressure was set at 200 MPa. Measure the concentration, freeness, transmittance (%), degree of polymerization, and sedimentation height of the nano-fine slurry that is reclaimed for each number of cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com