Caliper disc brake of a vehicle, in particular a commercial vehicle, and holding-down spring of such a brake

A caliper disc brake and compression spring technology, applied to vehicles, can solve problems such as the inability of the compression spring to be loaded favorably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

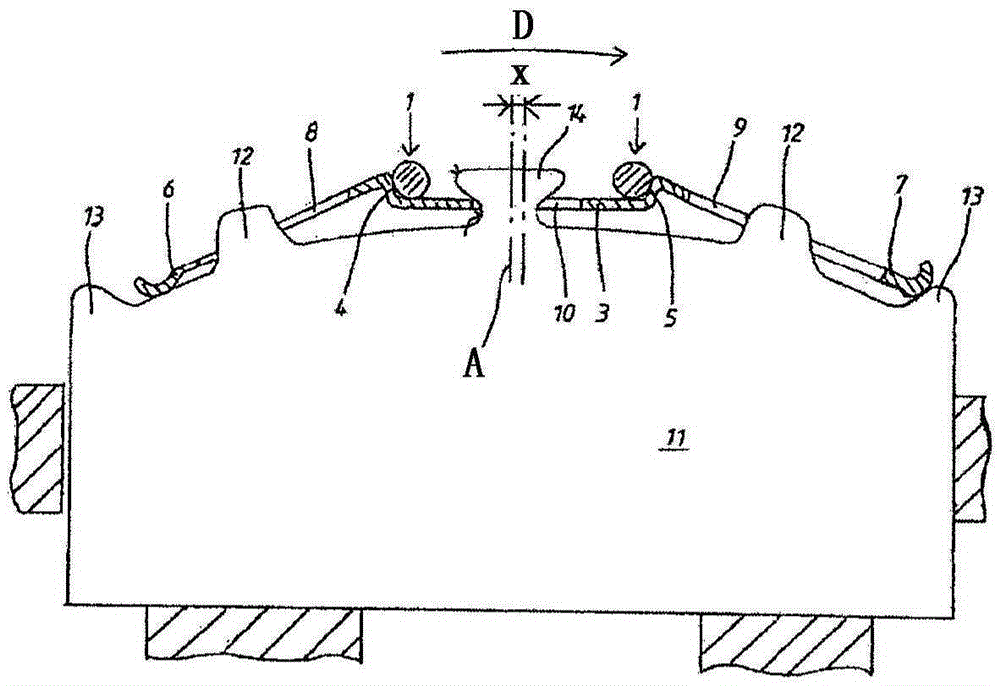

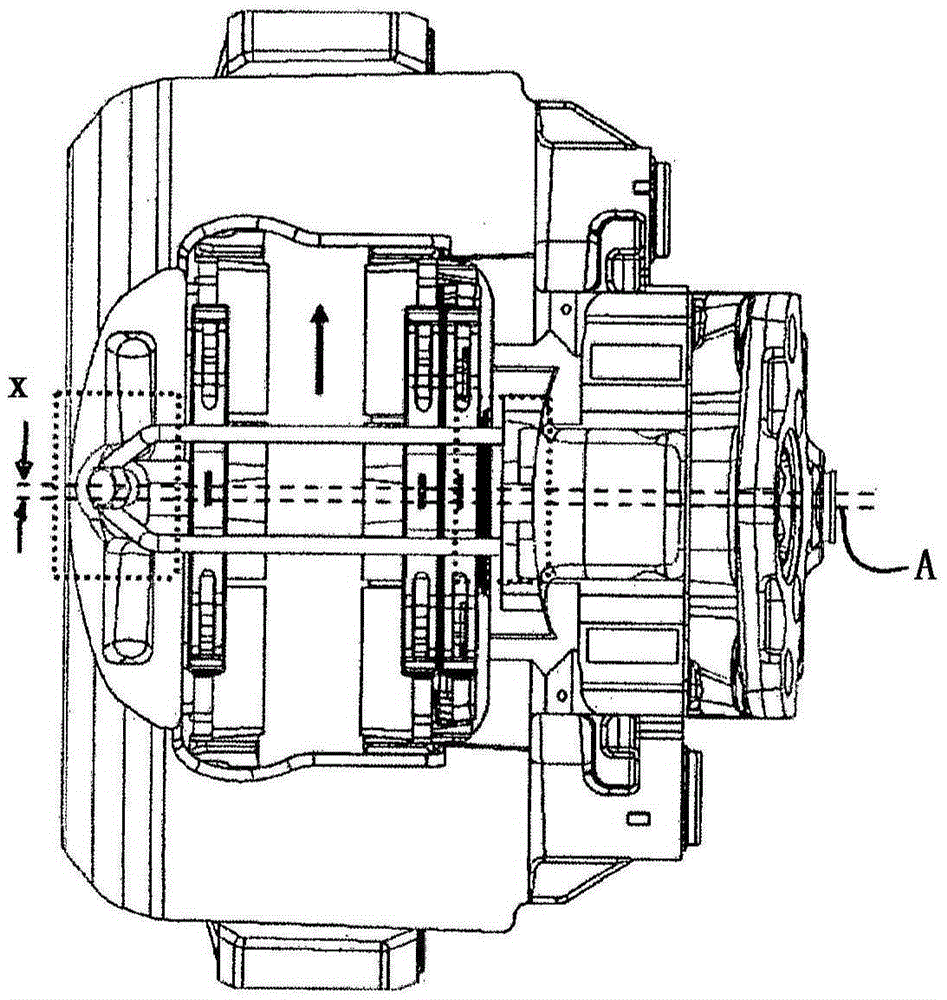

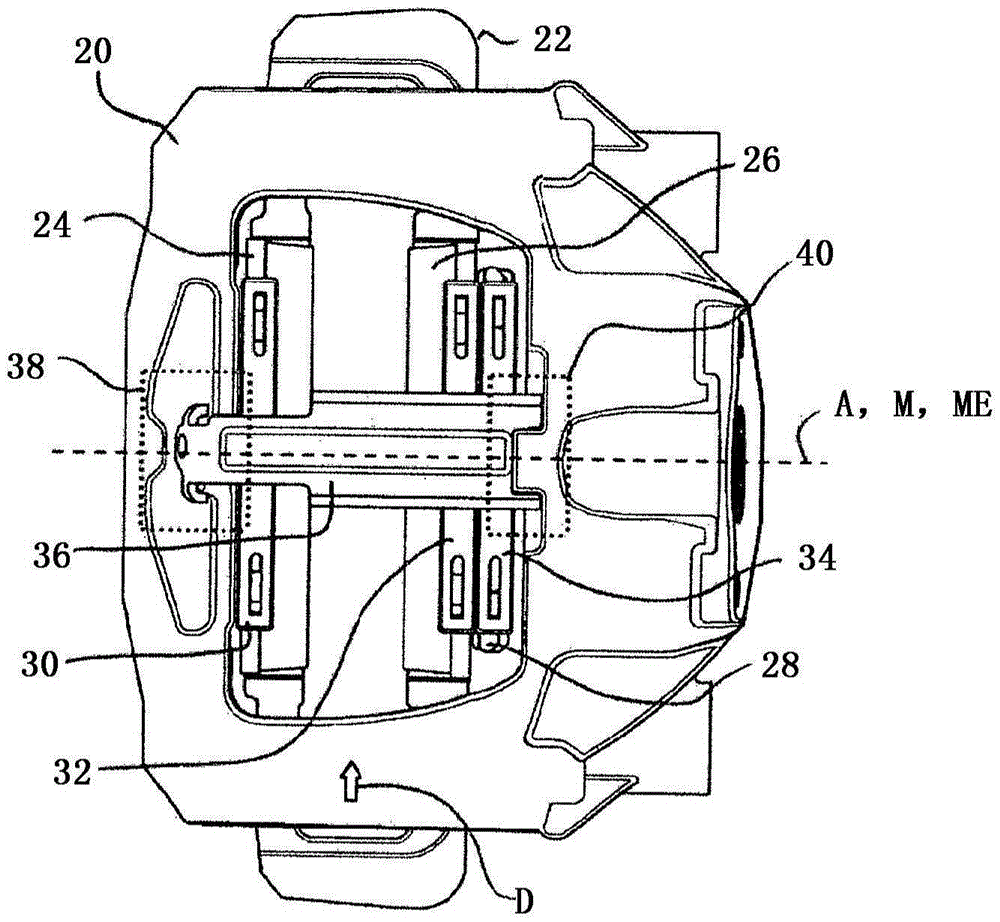

[0033] The exemplary embodiment of the disc brake according to the invention shown in the figures has a (not shown) brake disc, the axis of rotation of which is designated A. The direction of rotation when driving forward is marked with arrow D. The brake has a brake caliper 20 and a brake carrier 22 , wherein the brake caliper surrounds a (not shown) brake disk in a frame-like manner. The brake pad on the rim side, which is formed from a metal backing plate with friction lining, is designated with the reference numeral 24 , while the brake pad on the application side, which is formed from a metal backing plate with friction lining, is designated with the reference numeral 26 Note, the pressure plate is marked with reference numeral 28 . The elements mentioned are force transmission elements. The force transmission elements are compressed, ie prestressed in the radial direction, by the compression springs 30 , 32 or 34 . As will be explained later, the brake pads 26 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com