Double-shaft 360-degree all-dimensional high-speed movement feeling analog simulation device

A simulation, all-round technology, used in entertainment, entertainment devices, rotating manned vehicles, etc., can solve the problem of unsatisfactory results, can not meet professional training and entertainment simulation, can not provide 360-degree continuous output rotation motion simulation, etc. problem, to achieve the effect of reducing the rotational load and inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

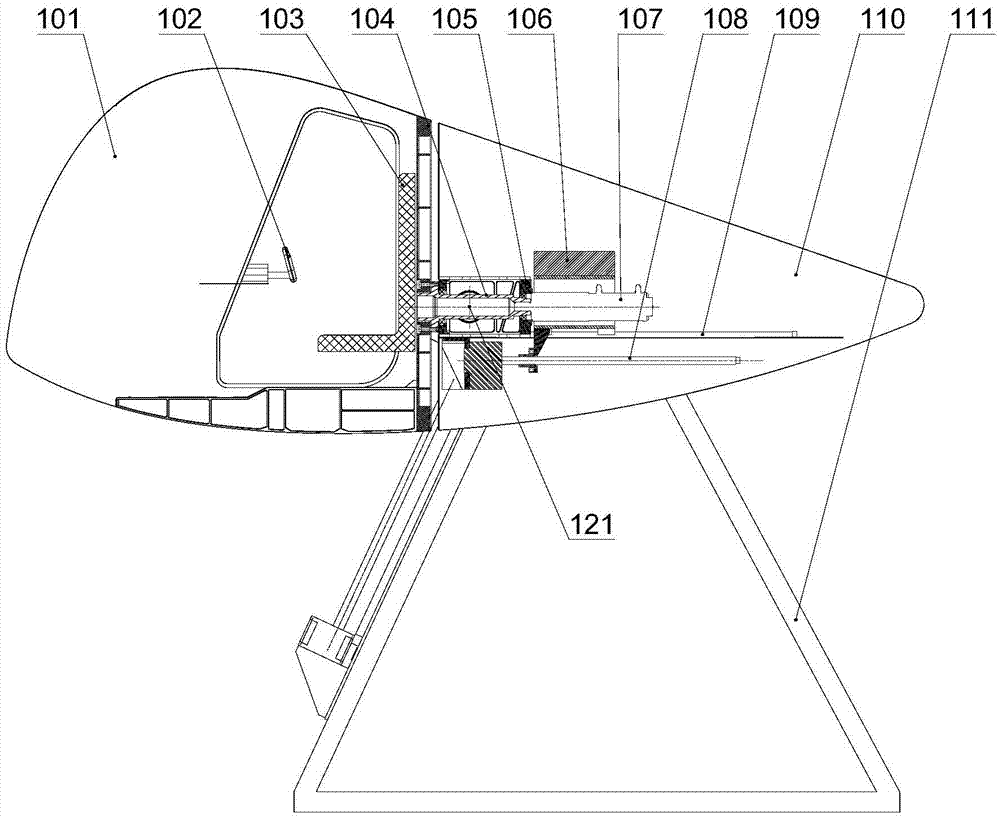

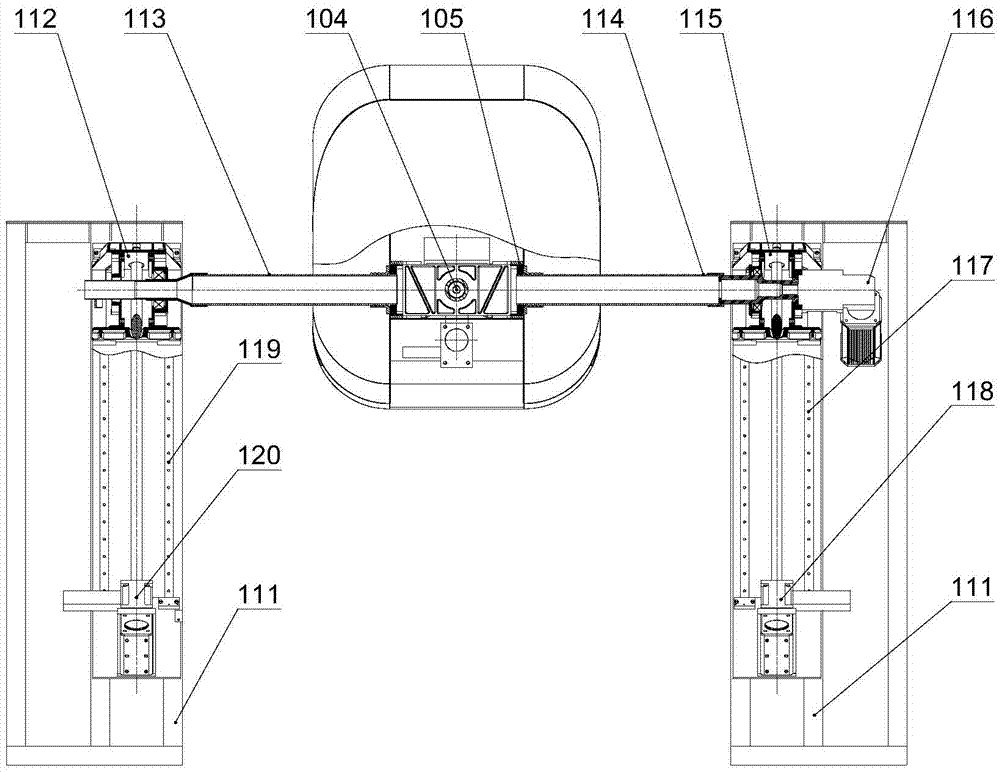

[0016] Embodiments of the present invention are described below with reference to the drawings.

[0017] refer to figure 1 , the cockpit includes a front cabin structure 101 and a rear cabin structure 110. Seats 103 and operation display devices 102 are installed inside the front cabin structure 101 to realize simulated operations of various equipment such as simulated aircraft, ships and vehicles. According to the present invention, it is possible to separately control the 360-degree rotation of the cabin body along the horizontal axis, 360-degree rotation along the vertical axis, and up and down sliding, or to simultaneously control these three degrees of freedom to perform compound movements, so as to realistically simulate the movement of various driving and riding equipment. Provide continuous and uninterrupted centrifugal force overload feeling.

[0018] The cockpit is arranged on the frame 111 via transverse axes 113 , 114 . Such as figure 2 As shown, the brackets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com