Environment-friendly agricultural automatic corn grain screening control equipment

A technology for automatic screening and control equipment, applied in the field of agricultural machinery, can solve the problems of complex structure of corn screening machine, affecting the health of operators, affecting the overall quality of corn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

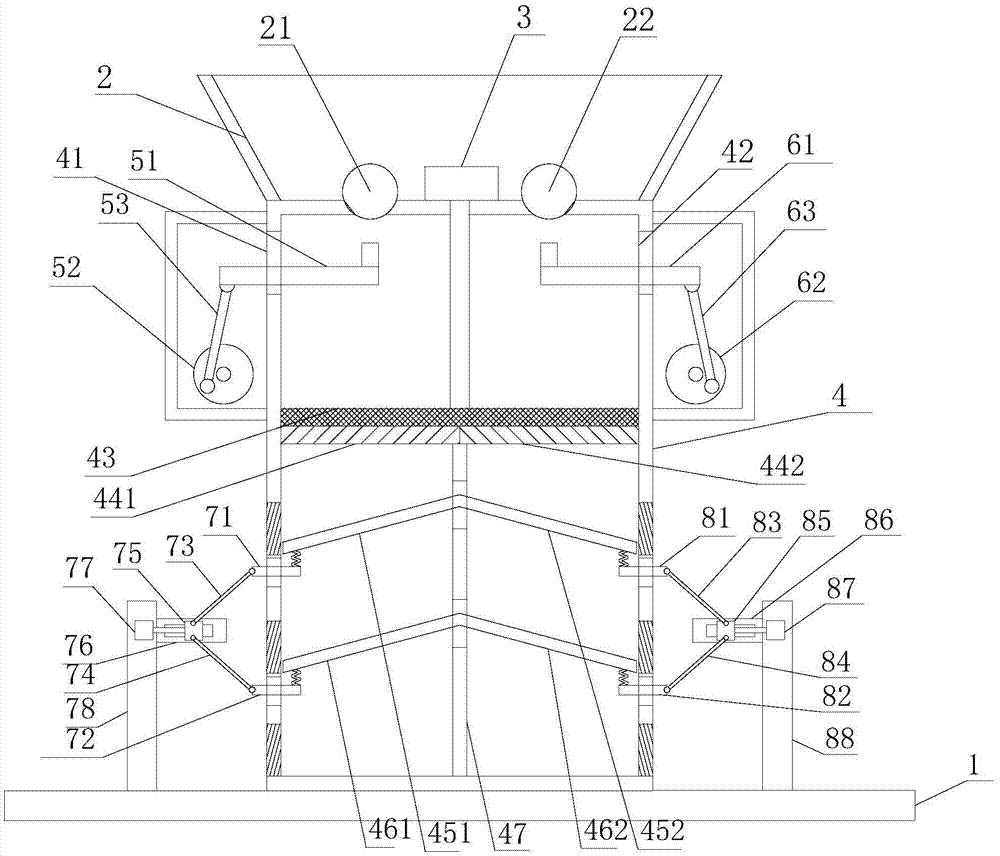

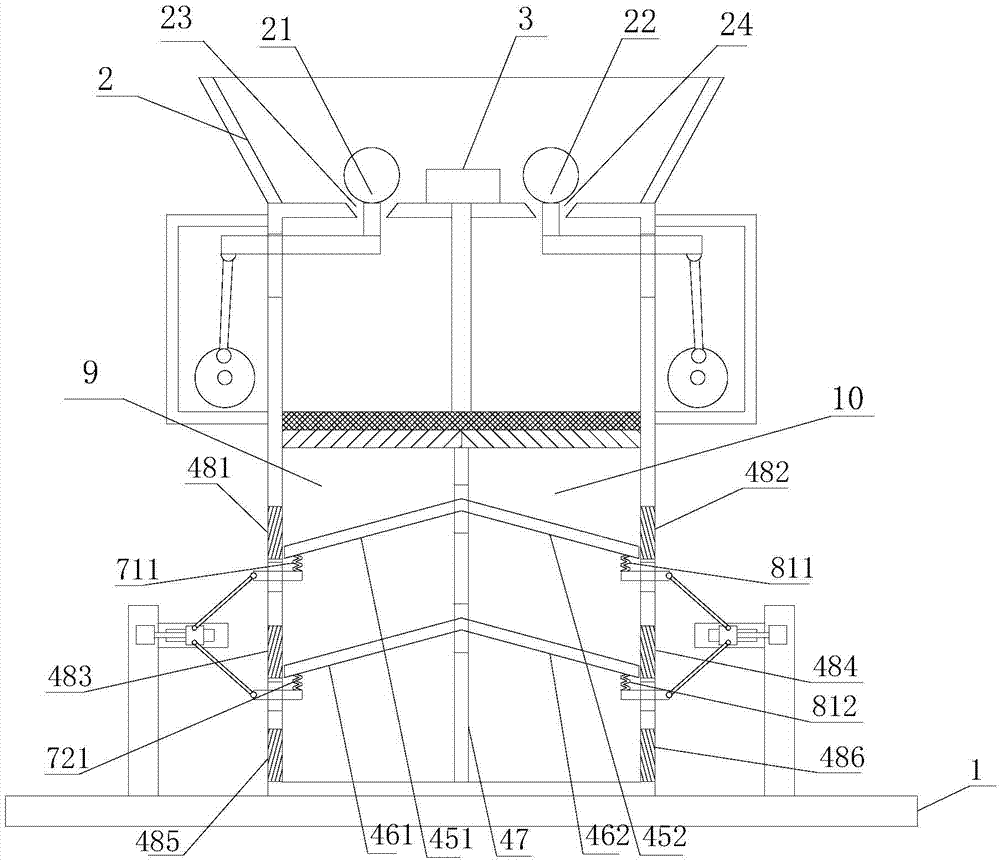

[0019] refer to figure 1 , figure 2, the present invention proposes an environment-friendly automatic screening control device for agricultural corn kernels, including a base 1, a feed funnel 2, a first piston jacking device, a second piston jacking device, a first driving mechanism 3, and a screening box 4. The second driving mechanism, the third driving mechanism, the control device, and the screening box 4 are installed on the base 1, wherein:

[0020] The discharge end of the feed funnel 2 is connected with the feed end of the screening box 4, the discharge end of the feed funnel 2 is provided with a first opening 23 and a second opening 24, and the first opening 23 is provided with a first movable ball 21 , the diameter of the first movable ball 21 is greater than the diameter of the first opening 23, and the first piston-type jacking device is movably installed on the screening box 4 for intermittently jacking up the first movable ball 21, the first piston-type jacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com