Spray production line and spray cleaning method

A technology for production lines and cleaning devices, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of poor cleaning effect and low cleaning efficiency of large valves, and achieve convenient transportation and improved effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a spray production line for large valves, including:

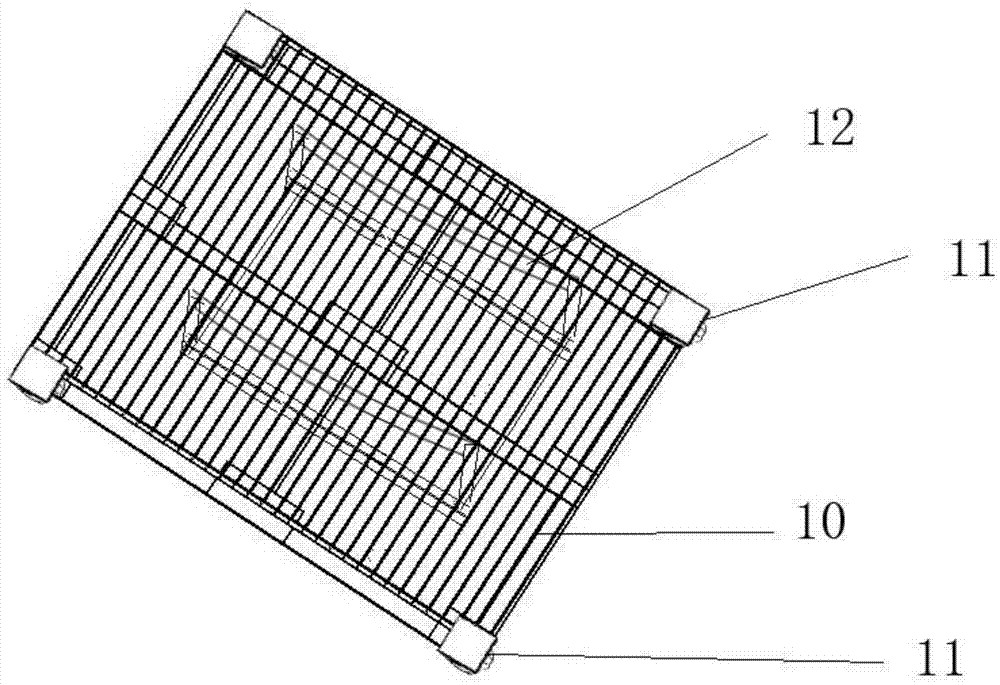

[0035] carrying device, such as figure 1 As shown, it includes a hollow base 10, a wheel 11 arranged at the bottom of the base, a fixing frame 12 arranged on the base, and the fixing frame 12 has two arc-shaped plates for matching with the valve body shape of the valve. Coordination; the hollow base 10 is to facilitate the cleaning liquid to pass through the hollow bottom when it is sprayed upwards, the wheels 11 are set to facilitate the movement of the carrying device, and the fixing frame is to facilitate the fixing and placement of the valve;

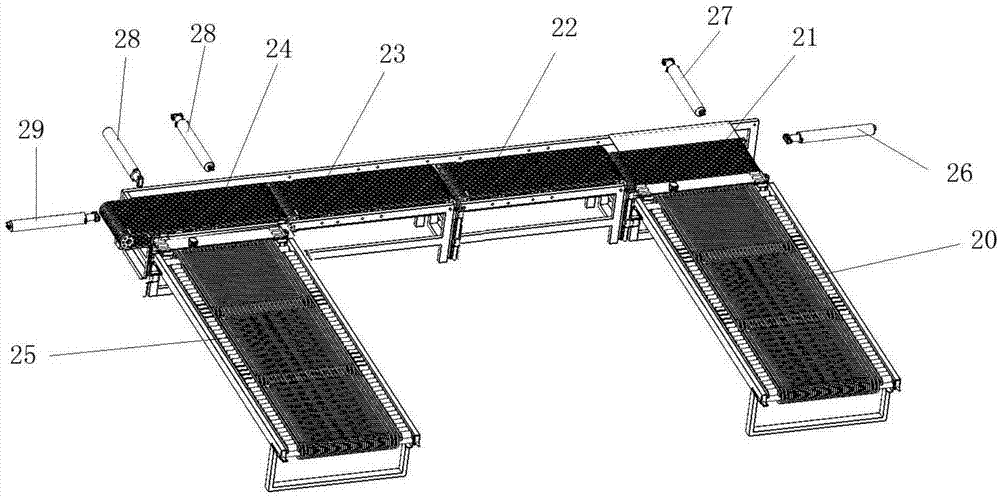

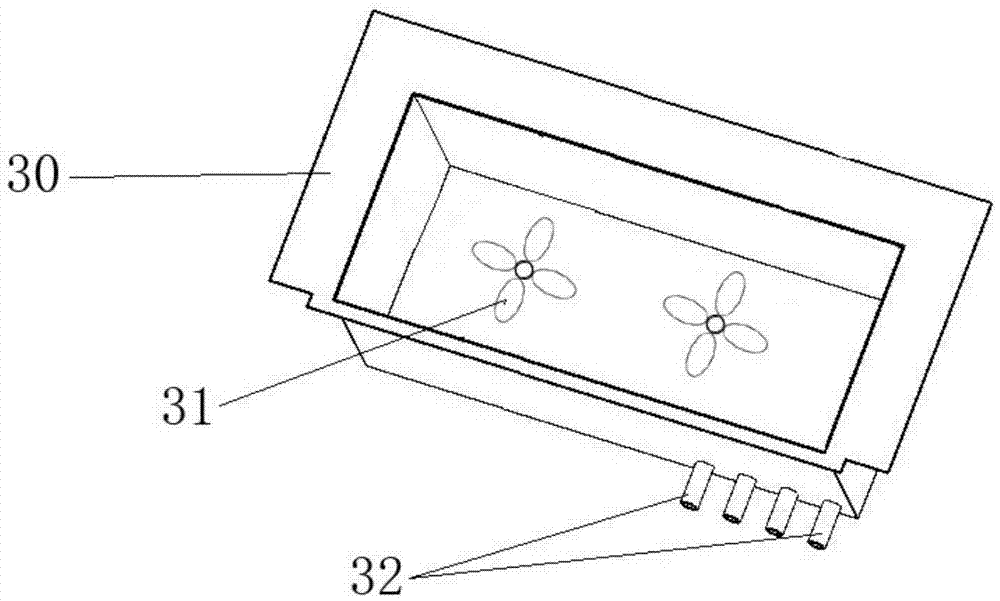

[0036] The cleaning device sequentially includes a first immersion device for rinsing the valve with cleaning liquid, a spray rinsing device for rinsing the valve in six mutually perpendicular directions with cleaning liquid, and a cleaning device for rinsing the valve with clean water. The second rinsing device for rinsing the valve, and the air...

Embodiment 2

[0068] This embodiment provides a large-scale valve cleaning method, adopting the large-scale valve production line described in Embodiment 1, comprising the following steps,

[0069] S1: Rinse the valve with cleaning solution. In this step, use the paddle to stir the cleaning solution. The rotation speed of the paddle is 100-150r / min, such as 100r / min, 120r / min, 150r / min, etc. The blade rotation time is 40-50min, such as 40min, 45min, 50min, etc. After using the paddle to stir the cleaning liquid, it also includes the process of cleaning the valve with ultrasonic waves. The ultrasonic frequency is 28kHz-35kHz, such as 28kHz, 30kHz, 35kHz, etc. , the power is 2-2.5w / cm 2 , such as 2w / cm 2 , 2.2w / cm 2 , 2.5w / cm 2 etc., ultrasonic cleaning time is 20-40min, such as 20min, 30min, 40min, etc.;

[0070] S2: Use cleaning liquid to flush the valve in six mutually perpendicular directions. In this step, the spray speed of cleaning liquid is 30-40m / s, such as 30m / s, 35m / s, 40m / s, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com