Waveform control circuit for alternate current argon arc welding machine

A technology for controlling circuits and argon arc welding machines, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of slow welding speed, reduced welding strength, unsatisfactory cleaning effect, etc., and achieve the reduction of welding time , increase the duty cycle, and enhance the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

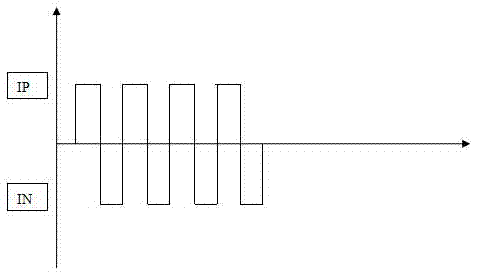

[0029] The waveform of the AC argon arc welding machine of the prior art is as figure 1 as shown, figure 1 IP is a positive wave, IN is a negative wave, the amplitude and frequency of the positive and negative waves are the same, and the positive and negative waves cannot be adjusted separately.

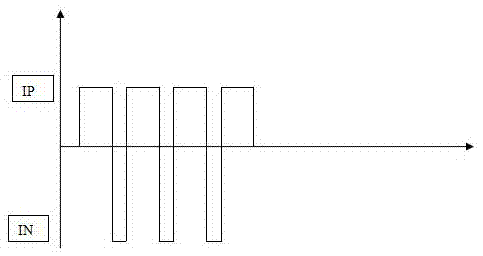

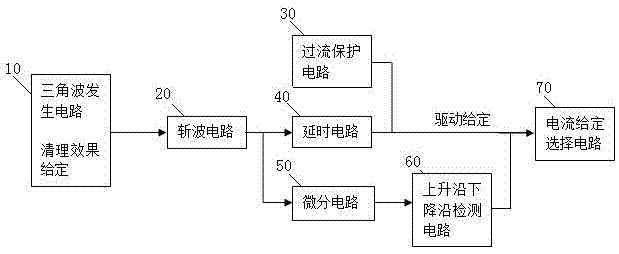

[0030] The principle of the present invention is to use an adjustable resistor to input the set cleaning effect, select the duty cycle of the square wave according to the cleaning effect, and determine the frequency according to the rising edge and falling edge of each driving waveform and two complementary square wave driving signals. Choose different current output, so as to achieve the purpose of different positive and negative output current of AC argon arc welding machine. Increase the output amplitude of AC negative, so that the cleaning effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com