Telescopic mechanism with simple and detachable roller wheel device

A telescopic mechanism and detachable technology, which is applied in the direction of wheels, transportation and packaging, railway car body parts, etc., can solve the problems of troublesome disassembly, damage of rollers, and reduce the effect of maintenance and other problems, so as to achieve convenient disassembly and installation, prevent derailment, improve Effects for changing speed and effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

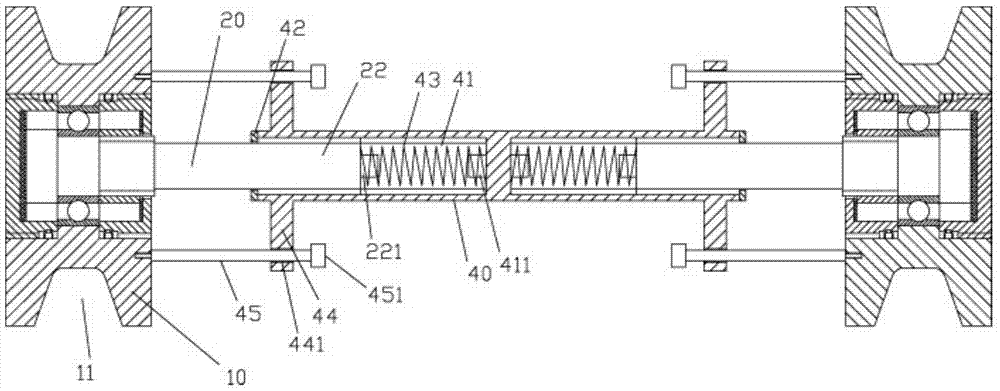

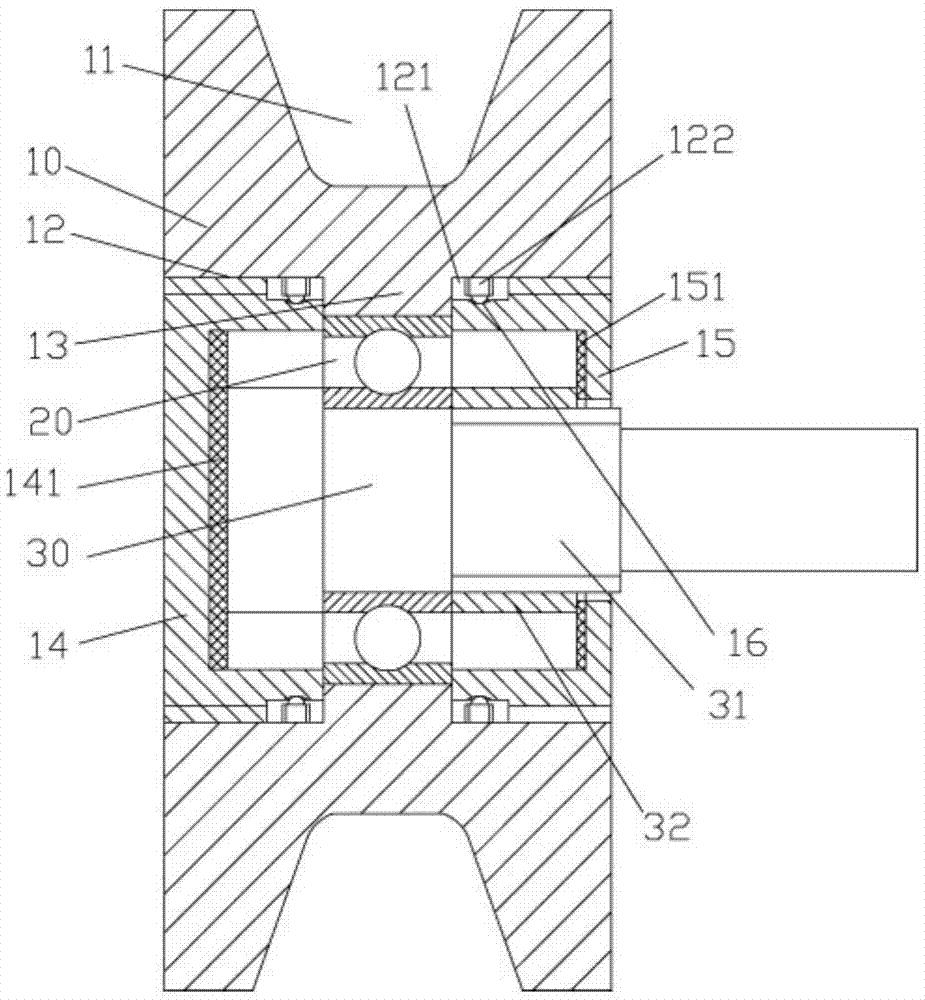

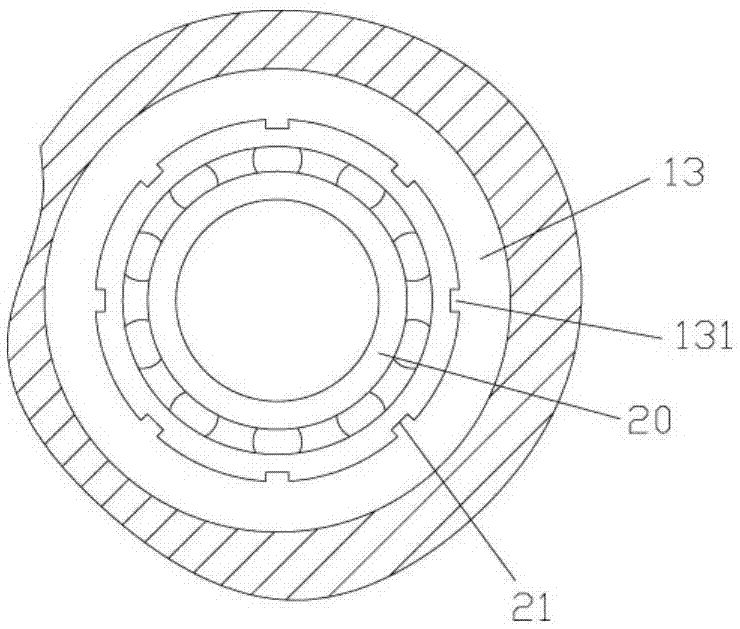

[0018] Examples, see e.g. Figure 1 to Figure 3 As shown, a telescopic mechanism adopting a simple detachable roller device includes two wheel bodies 10 and a middle connecting shaft body 40. The outer wall of the wheel body 10 has a wheel groove 11, and the middle part of the wheel body 10 has an axial The through hole 12 has a connecting raised ring 13 on the middle side wall of the axial through hole 12, and a plurality of raised strips 131 are provided on the inner side wall of the connecting raised ring 13, and the bearing 20 is inserted into the connecting raised ring 13, The raised bar 131 is inserted into the corresponding bar-shaped groove 21 on the outer side wall of the outer ring of the bearing 20, the rotating shaft 30 is fixed in the inner ring of the bearing 20, and the inner side walls at both ends of the axial through hole 12 have Internal thread, the outer end cap 14 and the inner end cap 15 are respectively screwed into the internal thread at the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com