Built-in guide oil cylinder

A technology with built-in guide cylinders and guide blocks, applied in the direction of fluid pressure actuators, etc., can solve problems such as unsatisfactory space and conditions, and achieve the effects of reducing radial shaking, strengthening radial guiding effects, and reliable guiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

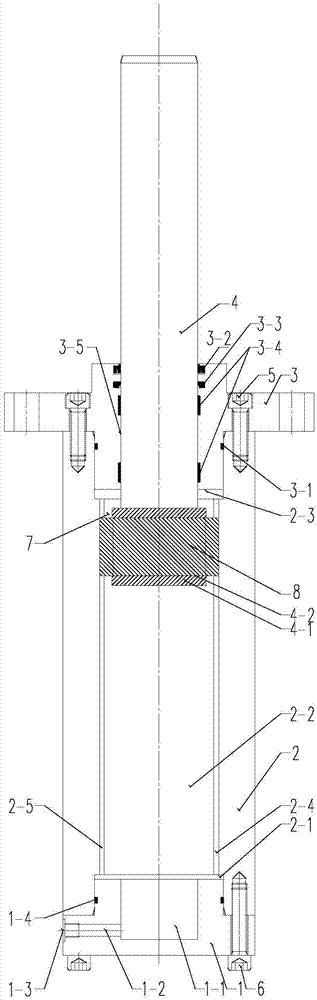

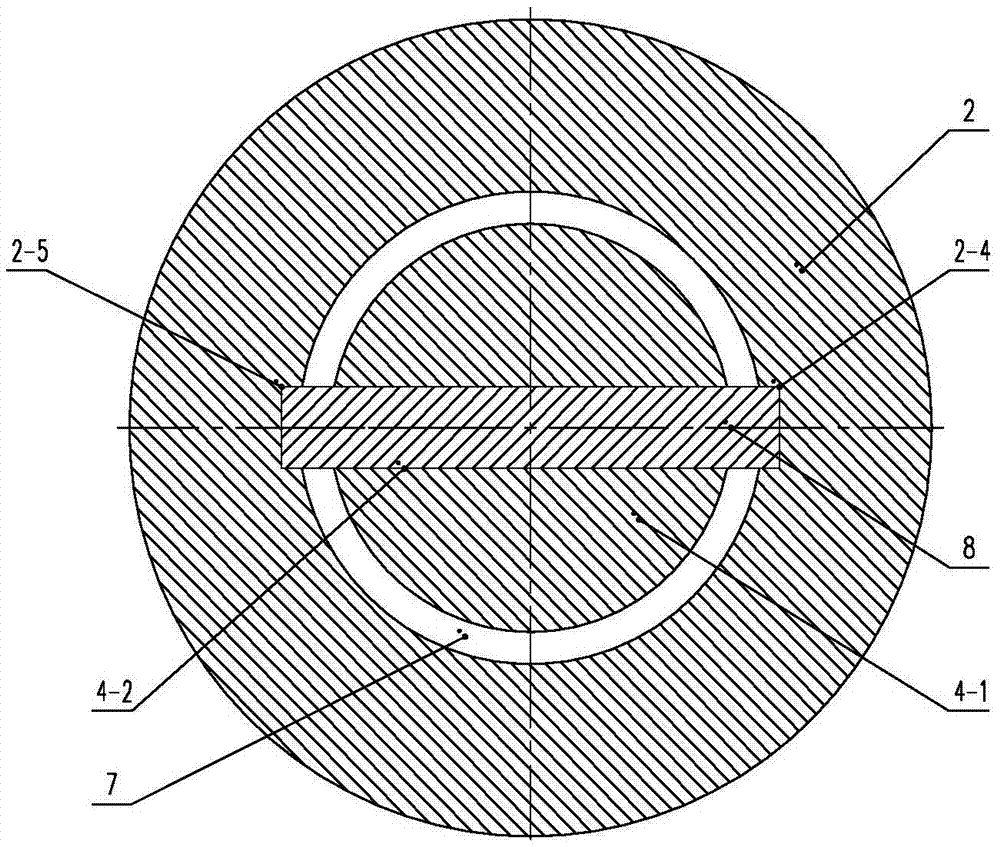

[0014] Such as figure 1 , figure 2 As shown, a built-in guide cylinder includes a lower end cover 1, a cylinder barrel 2, an upper end cover 3, a plunger 4, an upper screw 5, a lower screw 6 and a guide block 8. The lower end cover 1 is provided with a lower end cover oil cavity 1-1 in the middle and upper part, and a lower end cover oil inlet 1-3 and a lower end cover oil passage hole 1-2 are opened on the left side, and the lower end cover oil inlet 1-3 is connected through the lower end cover. The oil hole 1-2 communicates with the oil chamber 1-1 of the lower end cover, and the lower end cover sealing ring 1-4 is installed on the outer peripheral wall of the upper part of the lower end cover 1; The middle part is provided with a cylindrical hole 2-2 in the middle of the cylinder, and the upper part is provided with a cylindrical hole 2-3 in the upper part of the cylinder. The cylindrical hole 2-2 in the middle of the cylinder is respectively connected with the lower cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com