A Method for Reducing Mechanical Noise of Locomotive Blower Fan

A technology of blower and blower, applied in mechanical equipment, machine/engine, components of pumping device for elastic fluid, etc. problems, to achieve the effect of reducing radial shaking, reducing mechanical noise, and improving maintenance capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

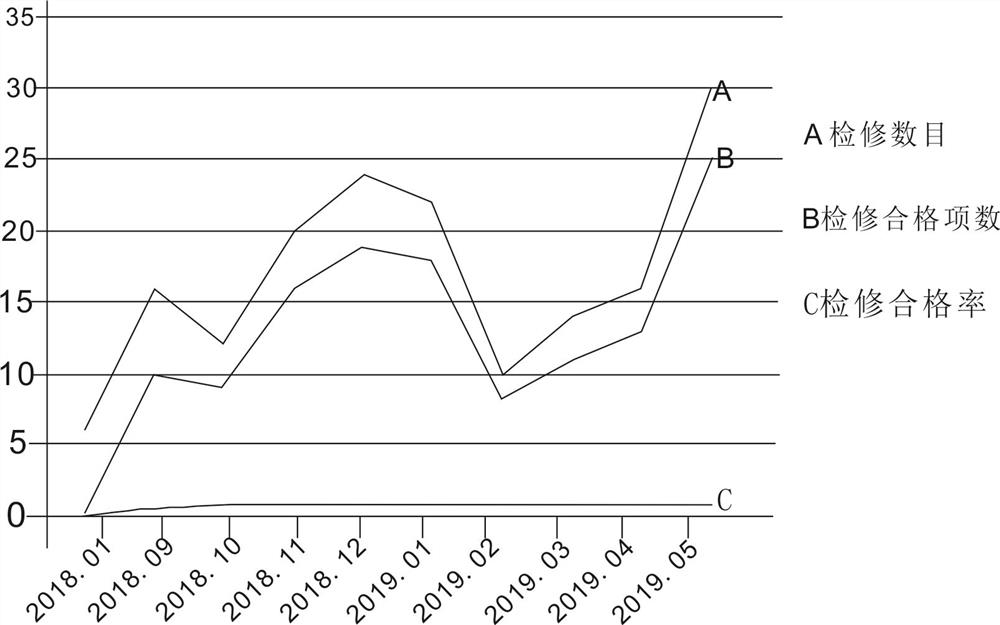

Image

Examples

Embodiment 1

[0025] Step 1. Disassembly of the rotor coil of the air supply fan: use a wrench to disassemble the plum blossom screwdriver on the outer cover of the air supply fan, and use the special tool for disassembling the rotor coil to remove the coil of the air supply fan; when using the special tool for disassembling the rotor coil , keep the force uniform, and prevent scratches on the surface of the rotor during the process of disassembling the coil and bearing;

[0026] Step 2. Disassembly of the rotor bearing of the blower fan: After the coil of the blower fan is removed in step 1, use the special tool for removing the rotor bearing to remove the upper bearing of the blower fan rotor; when using the special tool for removing the rotor bearing, keep Use uniform force to prevent scratches on the surface of the rotor during disassembly of the coil and bearing;

[0027] Step 3. Bearing replacement or oil filling: Use a measuring tool to measure whether the bearing clearance has incre...

Embodiment 2

[0031] Step 1. Disassembly of the rotor coil of the air supply fan: use a wrench to disassemble the plum blossom screwdriver on the outer cover of the air supply fan, and use the special tool for disassembling the rotor coil to remove the coil of the air supply fan; when using the special tool for disassembling the rotor coil , keep the force uniform, and prevent scratches on the surface of the rotor during the process of disassembling the coil and bearing;

[0032] Step 2. Disassembly of the rotor bearing of the blower fan: After the coil of the blower fan is removed in step 1, use the special tool for removing the rotor bearing to remove the upper bearing of the blower fan rotor; when using the special tool for removing the rotor bearing, keep Use uniform force to prevent scratches on the surface of the rotor during disassembly of the coil and bearing;

[0033] Step 3. Bearing replacement or oil filling: Use a measuring tool to measure whether the bearing clearance has incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com