Combined-type distributing valve group

A gas distribution valve and composite technology, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as complex circuit design of electronic control modules, increased vehicle power burden, and increased probability of component failure maintenance, etc., to achieve The effect of reducing the number of valve bodies and the control program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

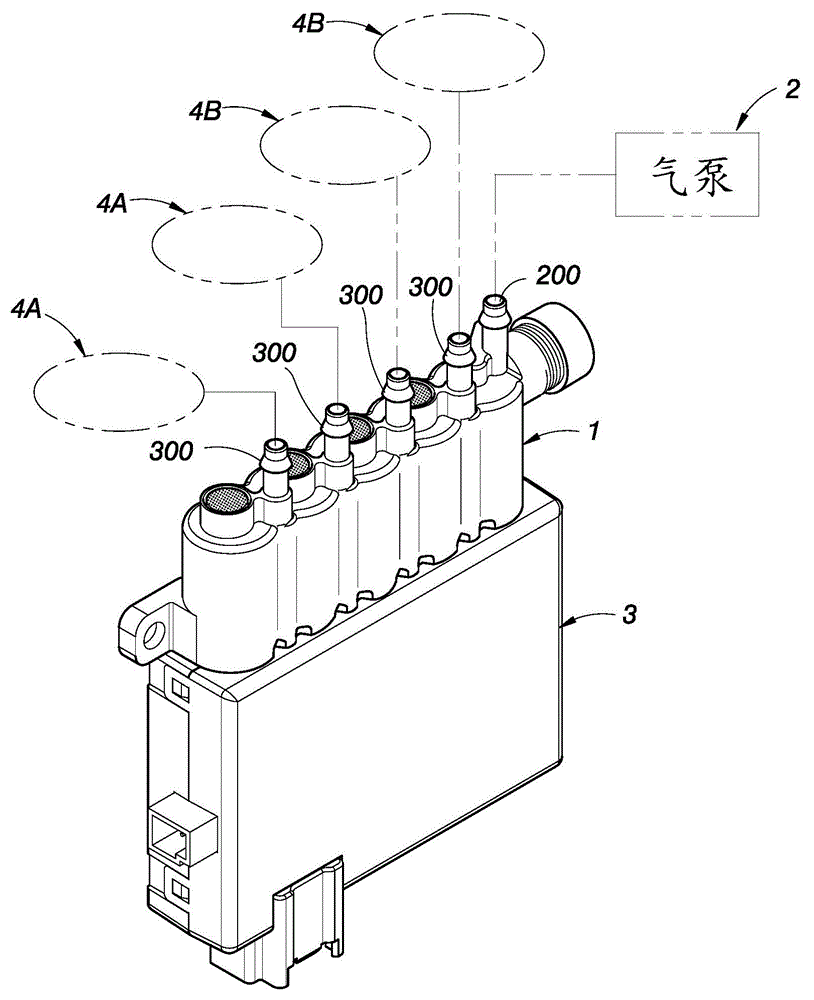

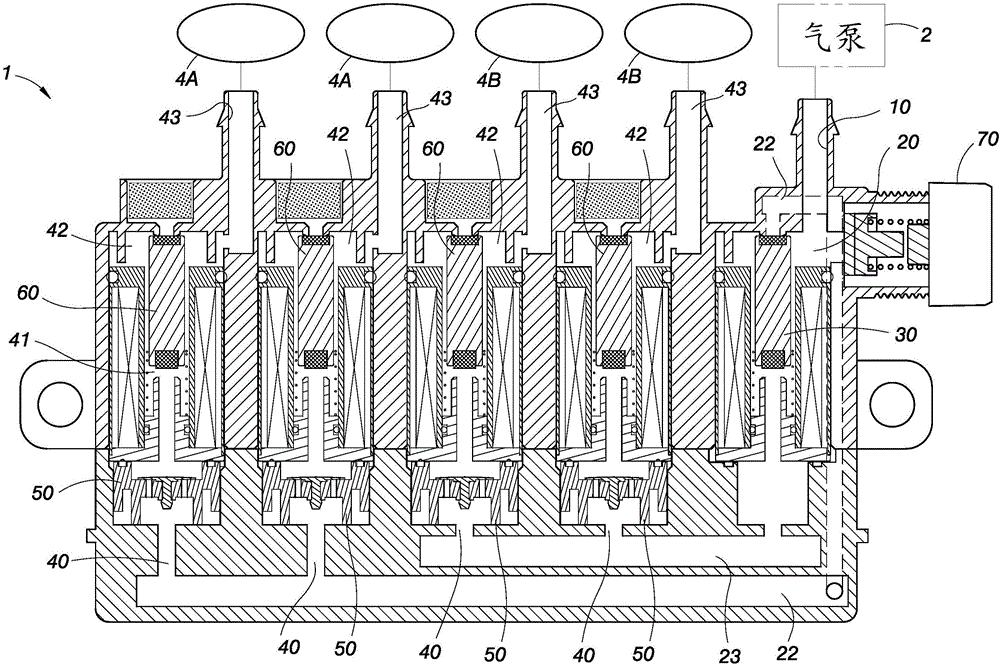

[0037] Such as Figure 1 to Figure 3 As shown, the composite gas distribution valve group 1 of the present invention is set in an inflation and exhaust system with an air pump 2 and an electronic control module 3 to inflate at least two groups of air bags, and the gas distribution valve group 1 has a The housing 100 sequentially includes a control air valve 200 electrically connected to the electronic control module 3 and at least two inflation and exhaust valves 300 from the air inlet end to the air outlet end. In the figure, one control air valve 200 and four inflation and exhaust valves 300 are taken as an example, in which two inflation and exhaust valves 300 inflate two first airbags 4A, and the other two inflation and exhaust valves 300 inflate two first airbags 4A. Inflate the second air bag 4B

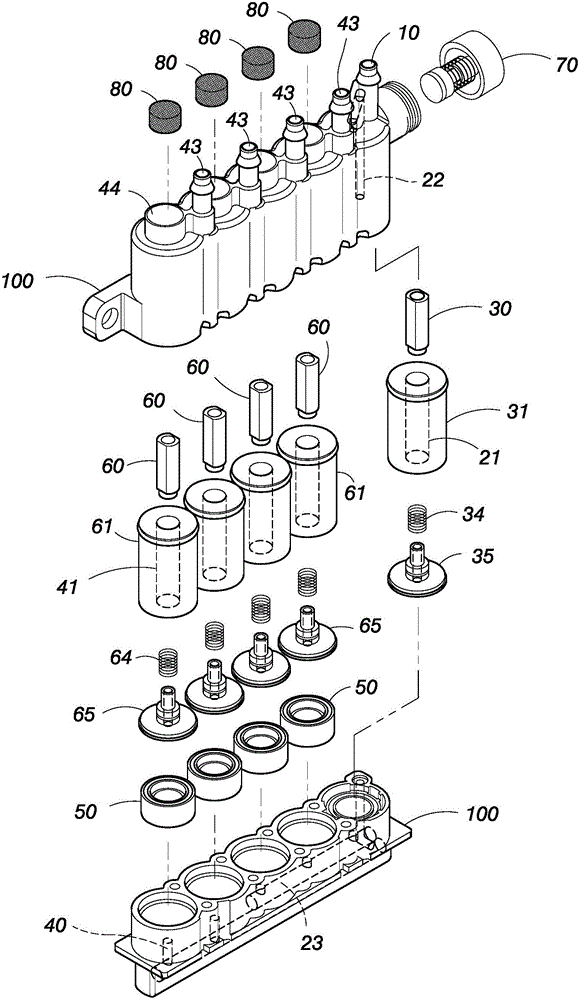

[0038] Please also refer to Figure 4 As shown, the control air valve 200 includes an air intake pipe 10 communicated with the air outlet of the air pump 2, an air intake cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com