Electronic cabin of an underwater robot with a stacked assembly structure

An underwater robot and assembly structure technology, applied in the directions of underwater operation equipment, transportation and packaging, ships, etc., can solve the problem of insufficient installation space inside the electronic cabin, difficult overall wiring inside the electronic cabin, and ineffective use of the curved space and other problems, to achieve the effect of improving space utilization, compact structure and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

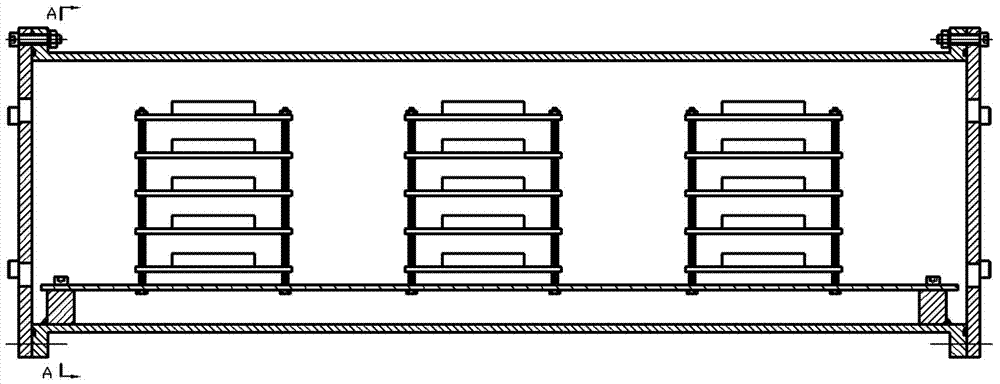

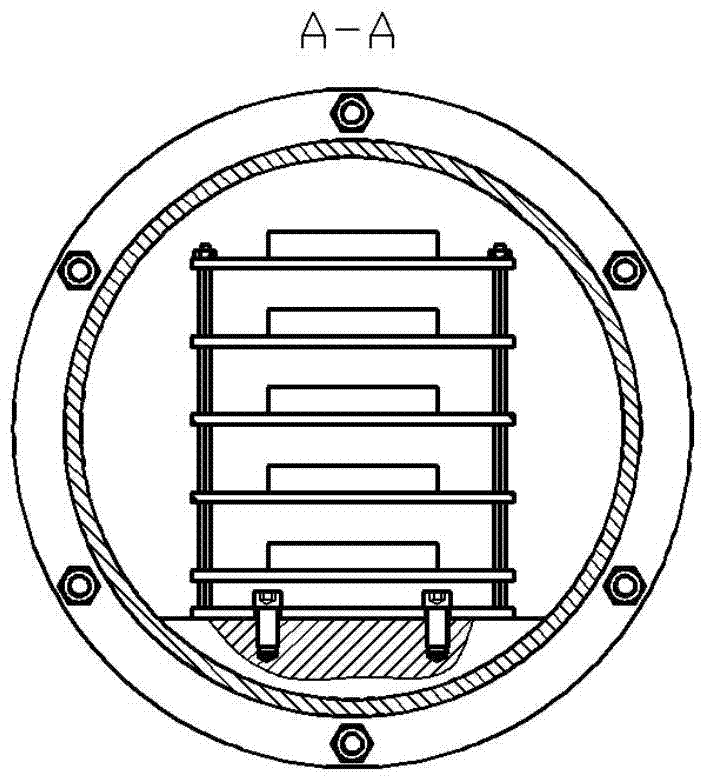

[0036] Attached below Figure 1-13 The patent of the present invention is described in further detail.

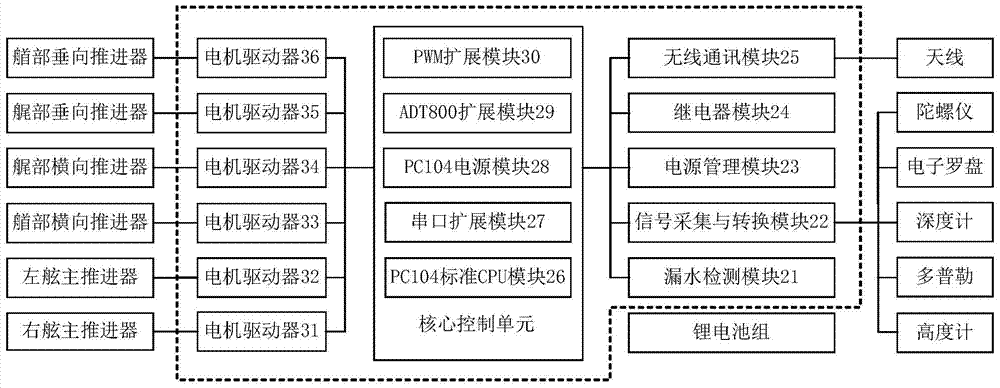

[0037] The patent of the present invention relates to an electronic cabin of an underwater robot with a stacked assembly structure, which is mainly composed of three parts: a pressure-bearing shell assembly, an electronic fixing frame, and an electronic module assembly. The pressure-bearing shell is installed on the underwater robot, and the inside is processed with a protrusion; the electronic fixing frame is composed of stainless steel screws, nuts, and spring washers to fix the circular bakelite board. The stainless steel screw protrudes outside the front panel. The end face is fixed with the internal protrusion of the pressure-bearing shell; multiple electronic modules adopt a stacked assembly structure on the electronic fixing frame, the normal direction of the module circuit board is parallel to the axial direction of the pressure-bearing shell, and the propeller moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com